Plastic pyrolysis – Chinaplas 2024, the premier international fair for the plastics and rubber industry, celebrated a remarkable return to Shanghai after a six-year hiatus, setting new attendance records 02-05-2024

Plastic pyrolysis

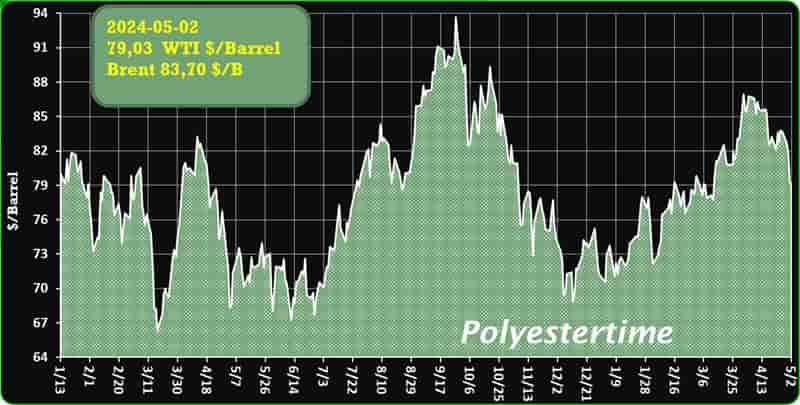

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

The Bulgarian company Plastchim-T has fully acquired the Italian firm Manucor

The acquisition from Milan-based financial company Pillarstone and minor stakeholders gives Plastchim-T ownership of Manucor’s facilities in Sessa Aurunca, Caserta. This site is noted for producing bi-oriented polypropylene (BOPP) films used in flexible food packaging, tapes, and various labels, generating approximately €150 million in annual revenue. Plastic pyrolysis

Plastchim-T, a direct competitor in the BOPP film market, operates three production sites in Bulgaria—Aksakovo, Dvnya, and Tervel—employing around 1,000 people.

The company boasts production capabilities of 115,000 tonnes per annum (t/a) of BOPP films, 12,000 t/a of cast polypropylene (CPP), 2,500 t/a of polyethylene (PE) film, and 10,000 t/a of flexible packaging. It also includes a 26,000 t/a hybrid BOPE/BOPP line.

In 2018, Pillarstone took a majority stake in Manucor, which increased to 95% in 2023, after the Russian company Biaxplen exited the venture. The remaining 5% was held by Manucor’s management. Plastic pyrolysis

The union of these two entities in the flexible film and packaging sector significantly enhances their production capacity to over 200,000 tonnes annually, positioning the newly formed group as one of Europe’s top BOPP film producers.

Investing in a plastic pyrolysis plant offers a multifaceted opportunity with numerous benefits

Let’s delve into the economic and environmental advantages of this innovative technology:

- Environmental Impact:

- Plastic Pollution Mitigation: With millions of tons of plastic waste generated globally each year, traditional disposal methods like landfilling and incineration are no longer sustainable. Plastic pyrolysis provides an alternative by converting plastic waste into valuable resources, reducing the burden on landfills and minimizing environmental pollution.

- Resource Conservation: Instead of relying solely on finite fossil fuels, pyrolysis allows for the production of fuel oil from plastic waste. This not only reduces the extraction pressure on natural resources but also contributes to energy diversification and security. Plastic pyrolysis

- Cleaner Fuel: The fuel oil derived from plastic pyrolysis has low sulfur content, leading to reduced emissions of harmful pollutants such as sulfur dioxide and particulate matter. It is highly versatile and can be used in power generation, heating, and industrial processes.

- Economic Opportunities:

- Job Creation: As governments worldwide implement stricter regulations on plastic waste management, there is a growing demand for sustainable solutions. Pyrolysis plants create employment opportunities in research, development, engineering, and manufacturing.

- Market Demand: The market for recycled products generated by plastic pyrolysis plants, including fuel oils and carbon black, continues to grow. These products find applications in various industries, making the investment economically promising. Plastic pyrolysis

- Circular Economy Principles:

- By converting plastic waste into valuable products, plastic pyrolysis enables closed-loop recycling, reducing the need for virgin resources and minimizing environmental degradation. This aligns with sustainable development goals.

- Technological Advancement:

- Companies continually strive to optimize the pyrolysis process, enhance product quality, and innovate in areas like catalysis and reactor design. This drives efficiency improvements and effectiveness in pyrolysis plants.

- Social Benefits:

- Investing in pyrolysis infrastructure in communities disproportionately affected by plastic pollution improves their quality of life and addresses environmental justice issues. Plastic pyrolysis

In summary, plastic pyrolysis technology offers a pathway to a more sustainable future, benefiting both the environment and the economy1234.

PET bottle recycling factory kicks off ‘trial’ operations in Al-Muwaqqar area

Econest Recycling, an Amman-headquartered leading recycler of PET bottles in the Middle East and North Africa region, announced start of trial operations for its factory specialized in recycling used plastic water bottles, with an investment amounting to $15 million.

Established in 2022, the factory, which is located in Al-Muwaqqar area, works to convert used plastic water bottles into polyethylene terephthalate, after recycling it with “high quality to become suitable for food use.”

In remarks to “Petra,” the company’s chairman, Mohammad Abu Sufa, said the factory, which is the first in the Middle East region, was established according to the “highest” international standards and “modern” European technologies, which ensure efficiency and excellence in all steps of the production processes, which would make its products “green and clean.” Plastic pyrolysis

Abu Sufa added that the factory’s mission aims to provide environmentally friendly solutions, revolutionize the recycling process, secure production inputs for multiple industries, achieve circular economy, protect the environment, and realize resource sustainability.

In the first quarter of the year, Versalis, a chemical subsidiary of the ENI group, reported a 12% increase in sales volume, reaching 900,000 tonnes

Despite this growth, the company experienced an adjusted operating loss of 168 million euros, marking an improvement over the previous quarter’s loss of 237 million euros due to cost optimizations, yet a 54% increase from the same period last year (109 million euros). This loss reflects weaker demand across all business segments, heightened production costs in Europe, and a less competitive stance against North American and Asian counterparts amidst an oversupplied market, according to the ENI quarterly report.

During the period between January and March, the plant utilization rate improved slightly from 52% to 57%. Plastic pyrolysis

However, the cracker margin has deteriorated compared to the same period in 2023. Furthermore, Versalis noted a decrease in margins on polyethylene and styrenics from last year, attributed to lower commodity prices and aggressive competitive pressures.

In mid-April, following these challenges, Versalis expanded its operations by acquiring Tecnofilm, a Marche-based company specializing in the development and production of functionalized polyolefins and thermoplastic compounds with elastomer properties. This acquisition is part of Versalis’ strategic efforts to enhance its product portfolio and market presence amidst fluctuating market conditions. Plastic pyrolysis

ENI – Versalis

Sinopec, Kazakh firm KazMunayGas to co-develop polyethylene project

China Petrochemical Corp, or Sinopec, together with KazMunayGas, a state-owned oil and gas company in Kazakhstan, will develop the biggest polyethylene project in Kazakhstan, the Chinese company said on Thursday.

Polyethylene is the most commonly produced plastic. A polymer, polyethylene is primarily used for packaging.

Sinopec signed an agreement with KazMunayGas in Xi’an, Shaanxi province, on Thursday for the joint implementation of the project in the Atyrau region of Kazakhstan, during the state visit to China of Kazakh President Kassym-Jomart Tokayev.

With a capacity of 1.25 million metric tons per year, the plant will be built on the territory of the special economic zone in Karabatan, close to the Tengiz field of the Atyrau region, Sinopec said. Plastic pyrolysis

To confirm Sinopec’s future involvement in the project, the two sides will sign a share purchase agreement and other legally binding documents. The final investment decision, called the FID, of the project participants is expected in 2024, it said.

Techtextil & Texprocess 2024 highlight future of textile processing

INSIGHTS

- Techtextil and Texprocess 2024 saw record attendance, with 38,000 visitors from 102 countries and 1,700 exhibitors.

- The fairs showcased innovative solutions driving cross-industry transformations in high-tech textiles.

- Texprocess highlighted advancements in digitalisation, automation, and AI, offering solutions for industry challenges and future growth.

High-tech textiles in twelve application areas, the global innovative power of technical textiles and nonwovens as well as the digitalisation of the textile-processing industry: with 38,000 visitors from 102 countries and 1,700 exhibitors from 53 countries, Techtextil and Texprocess have grown in terms of exhibitor numbers and recorded a 29 percent increase in visitor numbers. Plastic pyrolysis

At the leading trade fairs, the density of forward-looking textile solutions that are transforming entire industries was particularly noticeable.

Techtextil and Texprocess 2024 ended with 1,700 exhibitors from 53 countries, 38,000 visitors from 102 countries and a 29 percent increase in visitor numbers. The top visitor nations were Germany, Italy, France, Turkey and the Netherlands. The top exhibitor nations were Germany, Italy, China, France and Turkey. Countries such as Egypt, China, Indonesia, Kosovo, Luxembourg, Moldova and Thailand contributed to the expansion of exhibitors, among others. Plastic pyrolysis

Chinaplas 2024, the premier international fair for the plastics and rubber industry, celebrated a remarkable return to Shanghai after a six-year hiatus, setting new attendance records

From April 23 to 26, the event attracted an impressive 321,879 visitors, a 30% increase from last year’s edition in Shenzhen, which had 248,222 attendees. This surge in participation surpassed organizer expectations, who had anticipated 270,000 visitors based on the 180,000 from Shanghai’s last 2018 hosting.

Foreign attendance was notably strong, with 73,200 international visitors making up 23% of the total. The event’s peak came on its second day, seeing 118,687 entries. The fair’s venue, the National Exhibition and Convention Center (NECC) in Shanghai, sprawled over 380,000 square meters across 15 pavilions—an expansion of 12% from 2018. This space accommodated 4,420 exhibitors, also up by 12%. Plastic pyrolysis

Significantly, around forty Italian companies participated, grouped in a collective stand managed by Amaplast, the association representing Italian manufacturers of machinery and systems for processing plastics and rubber. This strong international presence underscores Chinaplas’s role as a crucial global platform for industry advancements and networking.

CHINAPLAS 2024

Plastic pyrolysis