Petrochemical PETPackaging Polyolefins 19-12-2020 - Arhive

Petrochemical PETPackaging Polyolefins

To address allegations of fraud in an October report from Hindenburg Research, Loop Industries (Montreal, QC) announced that it engaged Kemitek to perform an independent verification of its patented Gen II depolymerization technology. Loop Industries claims that the process recycles waste PET and polyester fiber into virgin-quality PET resin. Kemitek is a not-for-profit College Center for Technology Transfer that specializes in green chemistry and chemical process scale-up. Petrochemical PETPackaging Polyolefins

According to Loop Industries, Kemitek established a “rigorous and independent methodology” for the verification. The Kemitek team was on site at Loop’s Terrebonne, Quebec, facilities for 16 days to verify each step of Loop’s technology at mini-pilot (25 L reactor) and pilot scales (6000 L reactor) from feedstock (post-consumer waste PET plastic) to final purified monomers (DMT and MEG).

-Expansion of BOPP capacity in India / Plants for BOPET films in operation in Hungary and Thailand

The board of the Indian conglomerate SRF (Gurugram, Haryana / India; www.srf.com) has approved the construction of a second BOPP film plant and metallisation facility in Indore / India. The existing capacity of 45,000 t/y is to be more than doubled with an additional 60,000 t/y. Petrochemical PETPackaging Polyolefins

Construction is scheduled to take 20 months, so the new plant is scheduled to be operational by the end of 2022, at the earliest. The investment is estimated at INR 4.24 bn (EUR 47.4m) and is to be provided from debt and internal accruals. SRF cites growth in the BOPP market both in India and overseas as the motivation for the investment, as well as the goal of being able to serve the entire spectrum of BOPP products. Based on the current product mix, the existing plant in Indore is running at 100% capacity.

-INEOS Styrolution hosts groundbreaking ceremony for its new 600kt abs plant in Ningbo, China

- Additional resources for the world’s biggest ABS market

- Improved service offering for customers

- Investment reflects commitment to the company’s Triple Shift growth strategy

INEOS Styrolution, the global leader in styrenics, today announced its ground-breaking ceremony for its new 600kt ABS (acrylonitrile butadiene styrene) plant located in Ningbo, China. The development of the new site is part of INEOS Styrolution’s larger expansion plans into China, following an earlier acquisition of two polystyrene production sites in Ningbo and Foshan. Petrochemical PETPackaging Polyolefins

The location of the new site was selected because of its extensive access to feedstock supply options and excellent supply chain connection to customers. The new site is expected to be operational by 2023.

-Tomra, Stadler combine to provide Viridor MRF system

Sorting technology firms work together to equip Viridor’s Mason’s MRF near Ipswich, England. Petrochemical PETPackaging Polyolefins

The Stadler UK Ltd. business unit of Germany-based Stadler Anlagenbau GmbH has led a £15.4 million ($20.7 million) project to upgrade the Masons Materials Recycling Facility (MRF) near Ipswich, Suffolk, United Kingdom, that is operated by Viridor. In 2019, when it sought bids for the project, U.K.-based Viridor specified sensor sorting devices made Germany-based Tomra Sorting Recycling’s in its tender documentation.

The modernization of the facility is part of a 10-year Viridor-Suffolk County Council contract renewal. Viridor runs the MRF on behalf of the Suffolk Waste Partnership.

Viridor says the upgrade allows it to increase capacity from 65,000 metric tons per year to 75,000 (equivalent to 17 metric tons per hour). The plant is now operating at full capacity and at what the equipment firms call optimum processing levels.

Mondi has developed a paper-based packaging solution for Drylock Technologies’ baby diapers Petrochemical PETPackaging Polyolefins

The EcoWicketBags are recyclable, replacing the traditional plastic packaging for diapers

CO2 footprint is significantly reduced with the innovative new products due to the use of renewable resources

Mondi, a global leader in packaging and paper, has launched a new paper EcoWicketBag for Drylock Technologies’ baby diaper ranges, bringing sustainable paper-based packaging to the hygiene market globally.

The global hygiene products manufacturer approached Mondi to create a more sustainable alternative to its existing plastic diaper packaging that would travel well, have strong shelf-appeal, and protect the product – while also using renewable resources and significantly reducing its CO2 footprint.

-Weekly Resin Report: Spot PE, PP Prices Spiral Higher

Processors, many of whom were caught short of supply, flocked to the spot resin market last week seeking material, but demand continued to outstrip current resin availability.

Consequently, prices for both polyethylene (PE) and polypropylene (PP) continued to spiral higher, driven by ongoing production issues, rapidly rising feedstock costs, export demand, and domestic price increase pressures, reports the PlasticsExchange in its Market Update.

Few Prime railcars were spotted, although a steady trickle of off-grade cars passed through.Petrochemical PETPackaging Polyolefins

Resellers doled out limited Prime offerings from warehoused stocks; as material sold, they raised prices on new offerings.

“Though we cringed to ask for the ever-rising offering prices,” writes the PlasticsExchange, “if the right resin was found, transactions came together with relative ease.”

-Enval and SAIREM partner to accelerate plastic recycling process

UK-based recycling specialist Enval has selected SAIREM, the French leader in industrial microwave and radio frequency applications, to supply the microwave generators that will power its laminate recycling process.Petrochemical PETPackaging Polyolefins

Enval uses a unique proprietary pyrolysis technology for treating low-density packaging waste. Its process transforms plastic waste into oil feedstock to produce new plastic. Enval’s process enables the recycling of each of the laminate’s components into materials that can be reprocessed and put back into circulation.

To power its pyrolysis process, Enval has engaged SAIREM, which has four decades of experience developing and delivering microwave and radio frequency applications, to supply its microwave generators. The units provided by SAIREM will provide clean and efficient heating that will be used to create the required conditions in Enval’s pyrolysis reactor. Enval plans to use SAIREM’s products in all of its future plants.

The Environment Committee of the Swiss National Council (ESPEC) seeks to create incentives to increase the proportion of recycled material in packaging for beverages and cleaning agents. A motion passed on 1 September 2020 calls for the country’s Federal Council to introduce by 2025 a tax on disposable plastic products with packaging containing less than 25% recycled material.Petrochemical PETPackaging Polyolefins

The goal is to create incentives for the increased use of recycled materials and to make products in this type of packaging the preferred option. The lower-house committee argues that polyethylene and PET are already collected today and can be recycled without any loss of quality. However, the recyclates are currently not competitive with virgin material due to the higher prices.

-Australia’s Xefco develops World-First Antiviral Textile Technology to Fight COVID-19

XViroblock™ antimicrobial copper treated textiles effective at inactivating SARS-CoV-2 in as little as five minutes.

Australian-owned materials science and technology start-up, Xefco®, in collaboration with Swiss textile innovator, HeiQ, has developed XViroblock™, the world’s first thin-film antimicrobial copper surface treatment for textiles that is proven to exhibit significant viricidal activity against SARS-CoV-2.Petrochemical PETPackaging Polyolefins

Studies conducted by the Peter Doherty Institute for Infection and Immunity (Doherty Institute) showed textiles coated with XViroblock™ inactivated SARS-CoV-2, with significant inactivation occurring within five minutes of direct contact.

By developing textile treatments that provide rapid viricidal and antibacterial functionality, Xefco hopes to reduce transmission of disease by reducing the persistence of pathogens on treated surfaces.

“While the antimicrobial properties of copper are well-known, we have developed a unique process and technology to apply an ultra-thin surface coating of the metal onto textiles,” said Tom Hussey, CEO and Co-Founder, Xefco.

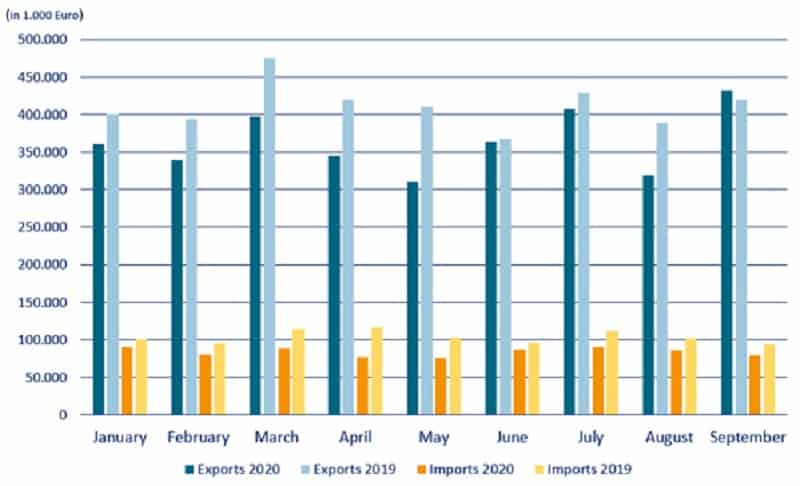

At the beginning of the year, the German plastics and rubber machinery industry, like almost all sectors of the economy, was hit hard by the effects of the Corona pandemic. However, the downward trend in sales and incoming orders already flattened out in mid-2020, and incoming orders even rose again from September onwards. Cumulatively, from January to October 2020 they are only 3% below the incoming orders in the same period of 2019.Petrochemical PETPackaging Polyolefins

According to Ulrich Reifenhäuser, Chairman of the Plastics and Rubber Machinery Association within the VDMA, the September and October months contributed significantly to this encouraging trend. “In September 2020, we had 13% more incoming orders compared to the same month of the previous year, and in October 2020, there were even twice as many orders on the books as a year ago”, Reifenhäuser said.

Petrochemical PETPackaging Polyolefins

Petrochemical PETPackaging PlasticAdditives 18-12-2020