Petrochemicals Biomaterials Generalnews 20-03-2021 - Arhive

Petrochemicals Biomaterials Generalnews

-r-PET : NEO GROUP started to produce PET resins with 25% recycled secondary raw materials

At the beginning of this year, UAB NEO GROUP, a PET producer operating in Klaipėda FEZ, produced and sent to customers for testing the first PET resins, which were manufactured using up to 25% of recycled raw materials. The company predicts that the commercial application – PET packaging – of this fully circular product will be presented to the market by converters in early May. In the next 3-5 years, NEO GROUP plans that recycled PET will account for 25-30% of the total production.

From the very beginning of NEO GROUP’s operations, only fossil raw materials have been used for the production of PET resins. However, by monitoring the market trends and preparing for the EU directive that will come into force in 2025, back in 2019, the company started experimental research in the laboratory by using the secondary, i.e. recycled PET (rPET) in the production process. After a year of trials, in 2020, on one production line NEO GROUP successfully produced food-contact PET resins with 15% of rPET, which in terms of quality and technical parameters were in the same high level as the primary raw material. And this year – PET resins with 25% rPET.

-Nylon 6 CS chip: an initiator of the industrial decline

CS chip was the first product declined in nylon industrial chain

As a product with the highest percentage of spot trading, nylon 6 CS chip market has been almost the most alert product during a volatile trend.

In the historical trend, CS chip market has been leading product in price decline and increase. Petrochemicals Biomaterials Generalnews

In the insight report “Nylon 6 CS chip into intensive profit-taking sales” released on March 2, the website has stated that nylon 6 CS chip market had stabilized after rapid increase since Feb 19, and sellers began to sell stocks actively at the profit-taking rate.

This “intensive profit-taking sales” window has ended after two weeks consolidation, and nylon 6 CS chip prices started falling sharply since Mar 9 to 14,100yuan/mt, close to the rate beginning the market after the Chinese Lunar New Year holiday (13,900yuan/mt on Feb 19).

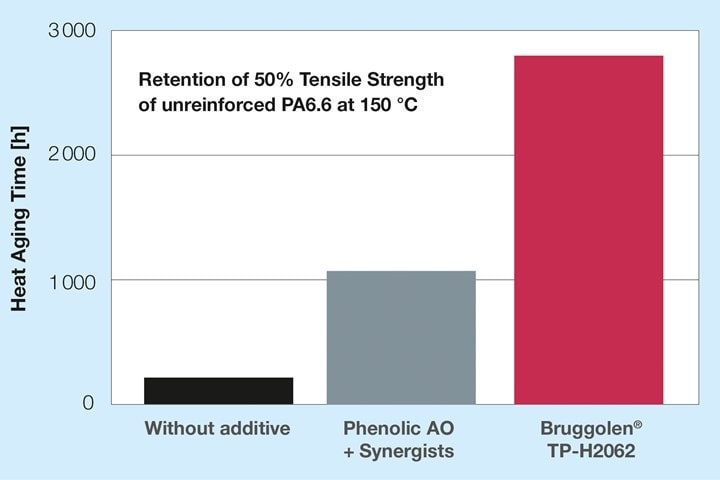

-Metal and Halogen Free Heat Stabilizer for Nylon E&E Applications

Brueggemann’s new Bruggolen TP-H2062 said to offer sustained protection for nylons in broad temperature range. Petrochemicals Biomaterials Generalnews

A metal and halogen free heat stabilizer for nylons used in electrical and electronic (E&E) applications that reportedly provides sustained protection in a temperature range of 248 F/120 C to 338 F/170 C is newly available from Germany’s Bruggemann (U.S. office is Newton Park, Penn.). Providing electrically neutral stabilization, Bruggollen TP-H2062 is said to prevent contact corrosion while at the same time maintaining the mechanical properties of the compounds even after long-term aging.

The new TP-H2062 is available as a dust-free, highly dispersible masterbatch. Depending on the application, its dosage can be adjusted to meet a wide range of temperature levels and profiles. Compounders supplying the E&E industry have for long been searching for a metal and halogen free heat stabilizing additive to preserve the integrity of nylon components at elevated temperatures as well as electrical properties like CTI, without causing electrical corrosion.

-japanese firms mull floating hydrogen infrastructure

Four Japanese companies will co-operate to develop a floating green hydrogen production and supply infrastructure project at a key Japanese port, hoping to tap growing demand for alternative marine fuel and help achieve the country’s 2050 decarbonisation goal. Petrochemicals Biomaterials Generalnews

Japanese shipbuilding venture Nihon Shipyard has teamed up with bunker supplier Mol Techno-Trade, industrial gas supplier Taiyo Nippon Sanso and engineering firm Kobelco Eco-Solutions to explore hydrogen production on a ship using renewable power and to supply the produced hydrogen as a marine fuel for coastal shipping.

The partners plan to start examining the floating green hydrogen project, named the SeaEra, in April.

-First fully automated sorting plant in Sweden

The new automated plant has a capacity of up to 4.5 tons per hour per line.

Sysav Industri AB is now operating the world’s first fully automated sorting plant for textiles recycling in Malmö, Sweden. Petrochemicals Biomaterials Generalnews

The plant has been built and designed by Stadler, headquartered in Altshausen, Germany, and integrates four Autosort units built by Tomra, of Asker, Norway.

It is part of the government-funded Swedish Innovation Platform for Textile Sorting (SIPTex) project, which aims to develop a sorting solution tailored to the needs of textile recyclers and the garment industry.

Sorting textiles according to the various types of fibres they contain requires a high degree of precision. It is currently done manually, but the result doesn’t meet the requirements of recycling companies and the fashion industry. As a result, only a small quantity of discarded textiles is recycled and the potential for increasing it is enormous. The SIPTex project is exploring how to achieve the required quality through automation.

-PolyREC created to report on Europe’s plastics circularity

Petcore Europe, PlasticsEurope, Plastics Recyclers Europe, and VinylPlus have mutually agreed to join forces to form PolyREC, which will monitor, verify, and report their plastics recycling and uptake data in Europe. Petrochemicals Biomaterials Generalnews

This will be achieved through RecoTrace, a common data collection system. PolyREC aims to ensure traceability, transparency, and trust in recycled materials along the entire plastics value chain by utilising VinylPlus’ 20 years’ experience and expertise in becoming the industry standard for collecting credible and reliable recycling data via its data collection vehicle Recovinyl.

VinylPlus’ Managing Director Brigitte Dero said: “The European PVC industry, through VinylPlus, has learnt the importance of monitoring and progress reporting. We are therefore pleased to share this long-time experience and work collaboratively with all plastic industry sectors to raise traceability and transparency.”

Color Star Technology Co., Ltd. (NASDAQ: CSCW) (hereinafter referred to as “Color Star” or the “Company”), today announced the signing of a cooperation agreement between its wholly-owned subsidiary, Color China Entertainment Co., Ltd. (hereinafter referred to as “Color China”), and Doman (HK) Ltd. (hereinafter referred to as “Doman”). The cooperation will provide blockchain technology support for Color Star’s interactive entertainment platform software, known as Color World APP.

Doman is a Hong Kong-based company that provides blockchain technology to many enterprises around the world, addressing issues in computing and internet management. Petrochemicals Biomaterials Generalnews

The cooperation between Color China and Doman will focus on several areas of blockchain technology, including entertainment copyright blockchain, membership management blockchain, and the development and application of interactive community blockchain. The cooperation will also include joint efforts to create a “private chain” and the continued pursuit of breakthroughs in augmented reality (AR) technologies. In addition, the cooperation may include mutually agreed strategic investments in each other.

The LYCRA Company, a global leader in sustainable fiber solutions for the apparel industry, has completed the Higg Facility Environmental Module (FEM) self-assessment at all six of its LYCRA® fiber manufacturing sites.

The robust impact assessment – which reviews environmental management systems, energy use, emissions, water usage, wastewater, and waste and chemical management at the facility level – helps manufacturing locations establish an environmental baseline to pursue continuous improvement.

The LYCRA Company’s Maydown site, located in the North West of Northern Ireland, piloted the module more than a year ago.

Based on initial learnings, the remaining five production facilities completed self-assessments simultaneously. Petrochemicals Biomaterials Generalnews

-CPG Company Launches Plant-Based Recyclable PET Packaging

Good Natured’s Bio-PET is food safe

While retailers, product manufacturers and food producers with sustainable packaging mandates have been limited to choose between petroleum-based, curbside recyclable and plant-based compostable options when it comes to their packaging, Good Natured Products Inc. is providing a different option: plant-based recyclable PET packaging. Petrochemicals Biomaterials Generalnews

A provider of earth-friendly plant-based products, the Canadian company has launched food-safe Bio-PET — a thermoformed packaging material designed to commingle in the recycling stream with petroleum-based packaging.

Vancouver, British Columbia-based Good Natured offers more than 385 sustainable products and services through wholesale and retail channels, including its own e-commerce stores. Its products combine the latest in plant-based renewable materials, eliminating BPAs, phthalates and other chemicals of concern.

-World biofuels output up to 3.3mn b/d by 2026: IEA

The IEA expects global biofuels production to increase by more than 25pc by 2026, after output fell last year for the first time in 20 years as the Covid-19 pandemic cut road fuel demand. Petrochemicals Biomaterials Generalnews

In its medium-term Oil 2021 report, the Paris-based group sees output rising to 3.3mn b/d by 2026 from 2.6mn b/d last year, underpinned by a recovery in mobility and road fuels transport demand. Strengthened policies and planned capacity additions will drive gains thereafter, the IEA said.

It estimates that global ethanol production will grow by 330,000 b/d from 2020 to 2026, and biodiesel and hydrotreated vegetable oil (HVO) output will increase by 380,000 b/d over the same period.

Gains in ethanol production will be driven by China, India and Brazil. The IEA expects Chinese output to increase from 70,000 b/d in 2020 to 160,000 b/d by 2026 thanks to robust gasoline demand growth, E10 mandates in some provinces and the start-up of new facilities. India’s ethanol production will rise from 30,000 b/d in 2020 to 70,000 b/d in 2026 following the country’s proposal to move its 20pc blending target forward to 2025 from 2030. Brazilian output could grow by 90,000 b/d to 660,000 b/d by 2026 as gasoline demand recovers and the country sets higher decarbonisation goals.

Petrochemicals Biomaterials Generalnews