Petrochemicals Plasticwaste Generalnews 19-03-2021 - Arhive

Petrochemicals Plasticwaste Generalnews

Crude Oil Prices Trend

-Waste-to-olefins technology nears commercialisation

Synova and Technip Energies have entered into a joint development and cooperation agreement to commercialise Synova’s advanced plastics waste-to-olefins technology, in conjunction with Technip Energies’ steam cracking technology.

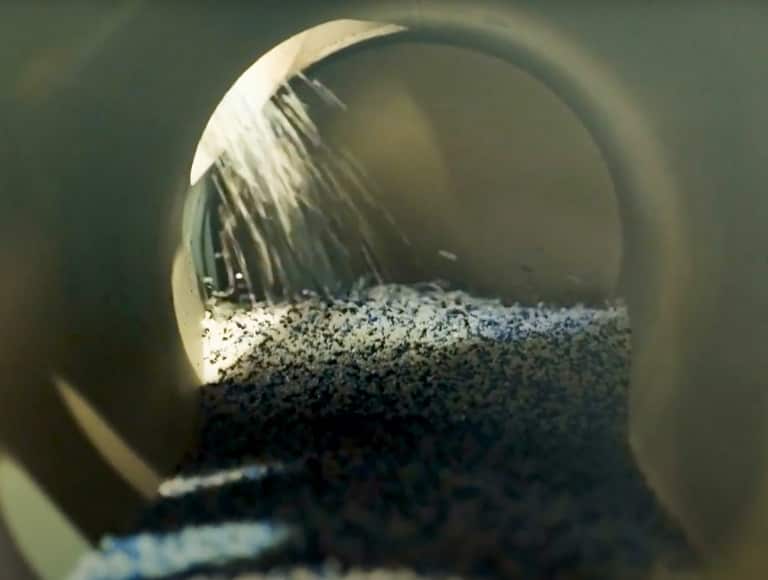

Synova’s patented thermochemical recycling technology takes dirty and mixed plastics waste, and break it down to its basic building blocks, such as olefin monomers and co-products, to produce circular plastics. The process, according to Synova, has a low carbon footprint and displaces the need for virgin polymers, in addition to reducing the need for intensive plastics waste sorting.

The Netherlands Organization for Applied Scientific Research (TNO), an independent Dutch research organisation, is credited as inventing the technology, which has been developed, tested and piloted in conjunction with Synova over a 15-year span.

-Packaging continues to steer PP market

Global polypropylene market revenue is likely to rise to $226.8 billion by 2030 growing at a 5.7 per cent CAGR during 2020–2030, according to P&S Intelligence.

The packaging sector accounts for the highest consumption of PP, while demand is shifting from PP homopolymers to copolymers. Petrochemicals Plasticwaste Generalnews

According to the research company, the key driver for the PP market is a rise in demand for the staple fibres made from this material among manufacturers of vehicle components and coating substrates. Petrochemicals Plasticwaste Generalnews

The Covid-19 pandemic saw surging demand for PP plungers, N95 masks and gloves. The market was, however, initially negatively impacted by the pandemic due to factory closures around the world.

Moreover, the slump in oil and gas exploration and production activities drastically reduced the availability of the raw materials required for creating PP.

-Benzene prices in Asia continue to decline

The price of benzene in Asia continued to decline this week, ICIS reported .

The increase in US oil inventories put pressure on the markets and weakened buying sentiment. So, on March 18, West Texas Intermediates (WTI) crude oil futures fell to about USD64 per barrel. Petrochemicals Plasticwaste Generalnews

Spot prices for benzene in Asia fell to USD830 per tonne FOB in Korea on March 17 from about US 850 per tonne FOB in Korea earlier in the week, according to ICIS data.

Meanwhile, the global economic recovery thanks to vaccinations in countries against Covid infection continued to inspire optimism with increased demand in the second half of the year.

Demand for imported benzene in China remained strong after the Lunar New Year holidays, with Chinese benzene prices higher than Korean ones, in stark contrast to the situation in 2020.

-Synova and Technip Energies Enter into Strategic Partnership

The agreement aims to commercialize Synova’s advanced plastic waste-to-olefins technology in conjunction with Technip Energies’ steam-cracking expertise.

Synova (Maassluis, Netherlands) and Technip Energies (Paris) have entered into a joint development and cooperation agreement to commercialize Synova’s advanced plastic waste-to-olefins technology in conjunction with Technip Energies’ expertise in steam cracking. Petrochemicals Plasticwaste Generalnews

Synova said that its patented thermo-chemical recycling technology closes the gap in the plastic supply chain by taking dirty mixed plastic waste and breaking it down to its basic building blocks, such as olefin monomers and co-products, to produce circular plastics. The process has a low carbon footprint and displaces the need for virgin polymers in addition to reducing the need for intensive plastic waste sorting, according to the company.

–Major Asian Producer Raises April PVC Prices for China by USD300 / Ton

A major petrochemical producer in Northeast Asia (NEA) has raised its polyvinyl chloride (PVC) bids for supply to the Chinese market in April by USD300 per tonne compared to March levels, market sources told ICIS .

Thus, the company’s April price proposals for China were announced at USD1,510 per ton, CFR China, without providing a discount for the supply of significant volumes of material, market sources said. Petrochemicals Plasticwaste Generalnews

For the markets of Southeast and North-East Asia (NEA), as well as for other regions, the company named April PVC price offers at the level of USD1,460 per ton, FOB NEA / SEA / other regions, which is also USD300 per ton higher than the level Martha. In these cases, the discount does not apply either.

The rise in bids was driven by a sharp decline in global supplies of the material amid disruptions in US production due to a winter storm in mid-February.

Earlier it was noted that in March this manufacturer increased prices for China by USD20 per tonne compared to the level of the previous month.

There has been a noticeable increase in demand for EREMA recycling machine combinations featuring ReFresher technology that reduces odour downstream of the extrusion process. Petrochemicals Plasticwaste Generalnews

This is due to the growing demand for high-quality post consumer recyclates that can be used for a wide variety of applications. Thanks to the combination of its INTAREMA® TVEplus® RegrindPro® machine with the ReFresher, EREMA has enabled the PCR-HDPE produced with it to be used in proportions of up to 100 percent for the production of packaging for direct contact with food and beverages, as confirmed by the U.S. Food and Drug Administration (FDA).

A look at the order books of the Austrian plastics recycling machine manufacturer shows that out of a total of more than 25 ReFresher modules sold, 19 were ordered in the past 18 months alone. This development goes hand in hand with the enormous increase in interest in the use of post consumer recyclate. “Odour is a typical problem with contaminated household waste such as LDPE films, HDPE containers and PE closures. It is essential that odour is removed if the PCR material is to be reused in high quality packaging for cosmetic products or food,” explains Clemens Kitzberger, EREMA Group Business Development Manager for Post Consumer Applications.

Broadly speaking, today’s carpet fiber market is characterized by two great divides-between low-cost PET filament and the higher-performing nylons, and between branded and unbranded fibers.

In terms of brands, the residential market is still dominated, for now, by a single independent brand, Invista’s Stainmaster, which competes against the vertically integrated fiber production of most of the major mills as well as unbranded fiber business. Petrochemicals Plasticwaste Generalnews

The commercial market is a more competitive field, where there are both vertically integrated mills and brands from the independent producers, like Invista’s Antron, Aquafil’s Econyl, Ascend’s Ultron and Universal Fibers’ range of fibers, including Thrive.

A lot can change in a couple of decades. At the turn of the century, staple fiber, mostly from independent producers, made up over 30% of the carpet and rug face fiber market-18% from nylon, 6% from polypropylene and 7% from PET (a form of polyester). And in terms of BCF (bulk continuous filament) fiber, 37% came from nylon and 31% from polypropylene. At the time, there was no BCF PET.

Back then, most of the carpet mills were supplied by four nylon suppliers (BASF, Honeywell, DuPont and Solutia), with vertical fiber integration still largely centered on polypropylene carpet production. There were a couple of PET suppliers, KoSa and Wellman, and two mills extruding their own PET from recycled drink bottles, Beaulieu’s Marglen and Mohawk’s Image.

Today, staple fiber is largely a thing of the past. PET filament technology yielded a viable product, and now over 50% of face fiber used in carpets and rugs is polyester-the vast majority of which is PET, with the balance from another form of polyester, Mohawk’s SmartStrand triexta (PTT) fiber-with nylon about ten points behind and polypropylene consumption in single digits.

Polyester is predominantly used in the production of residential broadloom. On the commercial side, almost all of the synthetic fiber in both carpet tile and broadloom is nylon 6 or nylon 6,6.

-Devan launches range of bio-based fragrances for textiles

The range consists of Natural Lavender, Menthol, Wild Mint, a Citrus Blend and will be expanded over time

RONSE, BELGIUM – Textile innovator Devan is launching a new range of bio-based fragrances, named SceNTL®. The range uses traceable raw materials and an external lab has confirmed that the bio-content of the fragrances is above 85%.

SceNTL® is a unique and wide range of encapsulated fragrances that can be integrated onto the fabric and are gradually released over time. Upon release, the fragrances appeal to the senses, promoting relaxation, wellbeing and feel-good sensations. Petrochemicals Plasticwaste Generalnews

While synthetic fragrances are composed of synthetic, man-made ingredients, natural scents and oils are created by isolating natural aroma components from raw plant materials. This also explains why every SceNTL® batch can have a slight variation in smell. As natural conditions differ from time to time, every harvest is a little different from the previous one.

-Germany’s chems Q4 production jumps 9.2% but Q1 more challenging – VCI

German chemicals production excluding the pharmaceutical sector jumped 9.2% in the fourth quarter, compared to the third, on the back of customer restocking but industry body VCI said conditions at the start of 2021 have been more challenging.

Customers looking to replenish empty warehouses toward the end of the year helped to galvanise the pace of recovery for chemicals, with production also substantially higher compared to the closing months of 2019. Petrochemicals Plasticwaste Generalnews

Including the pharmaceutical sector, the level total sector productivity moderated slightly to 7.4% quarter on quarter, with pricing firming 0.4% compared to the July-September 2020 quarter.

However, chemicals prices remained in the fourth quarter nearly 2% lower year on year.

LOCKDOWNS COOL DOWN OPERATIONS

Conditions were less unambiguously bullish in the opening months of this year amid lockdown extensions and fears of a fresh wave of infections in parts of Europe, with almost half of VCI members responding to a survey expecting setbacks for the quarter.

Aside from coronavirus fears, the extent that the manufacturing sector has heated up through 2021 so far has led to material shortages for German chemicals producers, exacerbated by the logistics issues brought on by the ongoing shipping sector disruption.

Can recycle almost all PET bottles that Hong Kong produces, plus a large proportion of HDPE, New Life executive says

Plant has sealed a three-year partnership with P&G and Watsons Hong Kong for supply of plastic waste Petrochemicals Plasticwaste Generalnews

The opening of Hong Kong’s first advanced plastic recycling plant mid-this year could kick-start a “closed loop” of turning household resin waste into recycled material, in line with the government’s waste blueprint.

New Life Plastics will process up to 100 tonnes of plastic waste a day, and turn it into secondary raw material to be reused in the manufacture of new resin products. It is a joint venture between Swire Coca Cola, Baguio Waste Management & Recycling and Alba, a German recycling giant.

“We have the capacity to manage virtually all PET [polyethylene terephthalate] bottles that Hong Kong produces, plus a large proportion of HDPE [high-density polythene],” said Nigel Mattravers, joint venture representative of New Life.

Petrochemicals Plasticwaste Generalnews