Petrochemicals CarbonFiber Textile 04-09-2020 - Arhive

Petrochemicals CarbonFiber Textile

Crude Oil Prices Trend

-Borealis buys controlling stake in South Korean compounder DYM Solution

The acquisition is designed to expand Borealis’ global wire and cable asset footprint.

In a move that expands its global wire and cable asset footprint, resin supplier Borealis has acquired a controlling stake in South Korean compounder DYM Solution Co. Ltd.

The financial terms of the deal have not been disclosed.

Based in Cheonan, South Korea, DYM Solution Co. Ltd. was founded in 1992 and is a provider of compound solutions for the global wire and cable industry. It specializes in semi-conductive, halogen-free flame retardant (HFFR), rubber and silane cured compounds.

-New appointments at Brückner Textile Technologies

As of 1 September 2020, Michael A. Tuschak will take over the position of Sales Director at Brückner Textile Technologies GmbH & Co. KG in Leonberg, Germany. Mr Tuschak succeeds Gerd Kolmer, who will hand over management responsibility after many years of service and focus on market development in selected countries and technologies. He will also continue to be available to his successor and the company with his extensive experience in all areas. Petrochemicals CarbonFiber Textile

“Mr. Tuschak has been working as a textile engineer and MBA International Marketing for over 25 years in the sales of textile machines, technical textiles and nonwovens and has many years of professional experience in leading positions,” the company said in a statement this morning.

-Picanol NV To Exhibit At CINTE TECHTEXTIL Shanghai

Picanol will be present at Cinte Techtextil in the Shanghai New International Expo Centre! Visit us at booth E3-A15.

Driven by extensive investments in R&D, Picanol has grown into an industry leader for high-tech weaving machines in the sector of technical textiles. The various developments made in recent years clearly highlight this point and have resulted in the growing success of our weaving machines in technical segments.Petrochemicals CarbonFiber Textile

The wide OptiMax-i rapier machines can be equipped with positive guided grippers in widths up to 212 inches (540 centimeters). This demonstrates how Picanol can efficiently replace obsolete projectile technology for such applications as agro-textiles, packaging, and carpet backings.

Picanol NV

-TUV Rheinland: Reducing Fibre Shedding When Washing Textiles

Microfibres released during laundry pollute the environment considerably / TUV Rheinland to support members of The Microfibre Consortium (TMC) to enhance understanding of fibre shedding from textiles / Information at www.tuv.com/textiles

It happens a million times every second, worldwide. Yet for many people it is happening in secret. “With every wash, textiles shed microfibres.

But while cotton, as an organic material, degrades almost completely, synthetic fibres persist in the environment much longer,” explains Heather Ball, responsible for textile testing at TUV Rheinland in Western Europe. Only a few days ago, researchers from the National Oceanography Centre (NOC) in Great Britain published their latest measurements of micro plastics in the Atlantic Ocean. Petrochemicals CarbonFiber Textile

The experts assume that an estimated twelve to 21 million tonnes of waste are found in the upper layers of water in the first 200 meters alone. This also includes fibres shed from synthetically produced fibres. “The problem has long been recognized by experts. The microfibres in the wastewater are not completely filtered out by sewage treatment plants and thus end up in the waters or as sewage sludge on the fields”.

TUV Rheinland

-LyondellBasell PP and HDPE technologies selected for petrochemical project in Oman

LyondellBasell (Rotterdam, the Netherlands) announced that Duqm Refinery and Petrochemical Industries Company LLC (DRPIC) has selected LyondellBasell’s world-leading polypropylene (PP) and high-density polyethylene (HDPE) technologies for a new facility, as per Chemical Engineering. Petrochemicals CarbonFiber Textile

The new plants will comprise of a polypropylene (PP) plant that will utilize LyondellBasell’s Spheripol PP process technology to produce 280,000 metric tons per year (m.t./yr) of PP and a 480-m.t./yr high-density polyethylene plant which will utilize LyondellBasell’s Hostalen ACP process technology and will be built in Al Duqm, Oman.

“LyondellBasell’s market leadership in polymer process technologies is once again confirmed with this significant award by DRPIC,” said Neil Nadalin, Director of Licensing at LyondellBasell. Nadalin added: “The selection by DRPIC of the Spheripol technology as the benchmark manufacturing platform for polypropylene resins and the Hostalen ACP technology as the leading low-pressure slurry process for the production of HDPE resins shows once again the confidence operators have in products produced with our technologies.”

-Innovative Companies Partner to Solve Plastics Waste Crisis

ePac Flexible Packaging and RePurpose Technologies Create Disruptive Solution for Plastics Recycling

ePac Flexible Packaging, the first company created based entirely on breakthrough digital printing from HP and RePurpose Technologies (RPT), which provides engineered product solutions through purpose-driven recycling, have announced a partnership to effectively solve the crisis that leads to 9 out of 10 pieces of discarded plastic waste polluting our environment*. The community-based model, which can be replicated easily, provides a transparent and economically viable solution that can once and for all cure the grave problem of our overflowing landfills. Petrochemicals CarbonFiber Textile

ePac operates a network of 18 community-based flexible packaging facilities in the US, United Kingdom, and Indonesia focused on supporting the growth of small and medium-sized companies. Through the power of digital printing every package produced can be serialized with a unique code that allows it to be tracked from production through reuse. Using IoT/Blockchain technology, data can be collected to provide tracking information to brands and retailers, while educating consumers about the package they just discarded and incentivizing them to practice a sustainable lifestyle.

-Heimtextil announces new trends for 2021/2022

eading trade show, Heimtextil, has launched the motto of the trend season 21/22, with the overarching theme ‘Nothing New, Everything New’.

The trends will provide an outlook on the design topics for the leading international trade fair for home and contract textiles, which will be held from January 12-15, 2021, in Frankfurt am Main, Germany, in hall 3.0. Petrochemicals CarbonFiber Textile

Together with the Heimtextil Trend Council, the management established a trend forecast for the coming season and presented it live via an online conference.

The subsequent design topics are already brought to life in the trend book, which is available now. In terms of trends, this season’s highlight is the comprehensive presentation offering during Heimtextil, according to a press release by Messe Frankfurt.

-Why Bioplastics Will Not Solve the World’s Plastics Problem

Bioplastics are being touted by industry marketers as the solution to plastics pollution. But the idea that bottles and packaging made of plant-based material can simply be discarded and then break down and disappear is false – recycling and reuse are the only strategies that can work. Petrochemicals CarbonFiber Textile

Coca-Cola calls it the PlantBottle — a new kind of recyclable plastic container, 30 percent of which is made from sugar cane and other plants, with the remaining 70 percent made from traditional oil-based plastic. The company says that PlantBottle packaging now accounts for nearly a third of its North American bottle volume and seven percent globally.

Does the PlantBottle mean the giant soft drink company has cracked one of the world’s most serious environmental problems, the choking of the world with oil-based plastics that never completely break down and disappear? Hardly. Though companies like Coca-Cola and Pepsi are under public pressure to solve the problem of plastic pollution, they have so far been unable to find a material or method as cheap and effective as single-use plastic.

-How AI and Robotics are Solving the Plastic Sorting Crisis

“If present trends continue, by 2050, there will be 12 billion metric tons of plastic in landfills.

That amount is 35,000 times as heavy as the Empire State Building.” If that isn’t a rallying cry, what is? Petrochemicals CarbonFiber Textile

The United States makes up 4% of the world’s population but produces more waste-to-population than any other country at 12%. “ India and China make up more than 36% of the world’s population and generate 27% of the world’s waste.

To make things worse, the U.S. needs help when it comes to disposing and reusing waste. Each year, approximately 90 million tons of extremely useful recyclable products are thrown away and sent to landfills,” said Chris Werth, VP of Marketing for AMP Robotics.

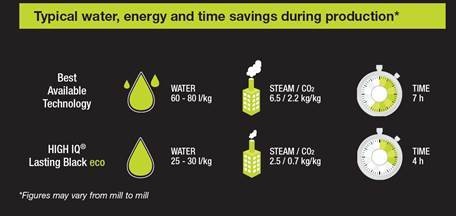

-Huntsman introduces High IQ Lasting Black eco program

Huntsman Textile Effects has extended its industry-leading High IQ brand assurance program with the launch of HIGH IQ Lasting Black eco.

Based on Huntsman’s award-winning Avitera SE Black reactive dye, the new colour-retention program will help mills, brands and retailers meet global demand for eco-friendly black shades that retain their intense colour even after repeated washing, Huntsman reports. Petrochemicals CarbonFiber Textile

“Black shades are an ever-popular choice among designers and consumers, offering visual appeal and timeless style. Leading brands today need to not only deliver intense black shades that won’t fade but must also show that they are sustainable and good for the environment,” the Singapore headquartered company says.

“High IQ Lasting Black eco is a unique combination of the world’s leading colour-retention program with Huntsman’s revolutionary Avitera Black SE reactive dye,” it adds.

Petrochemicals CarbonFiber Textile