Polymers protect us from the elements, increase the fuel efficiency of cars, protect food from pathogens, help cure disease, and enable renewable-energy technologies. To promote, foster, and enable a sustainable society, we need polymers.

Polymers protect us from the elements, increase the fuel efficiency of cars, protect food from pathogens, help cure disease, and enable renewable-energy technologies. To promote, foster, and enable a sustainable society, we need polymers.

Yet polymers can also create serious environmental challenges. Nearly all plastic packaging produced—more than 80 billion kg annually—originates from fossil resources and is disposed of after a relatively short period of use (1, 2).

An increasing fraction of plastic is recycled or incinerated to recover energy, but most ends up in landfills, littering cities or landscapes, and in the oceans (3).

New recycling concepts (4), clean incineration, and the development of polymers that can rapidly degrade (5) will be key to addressing these problems.

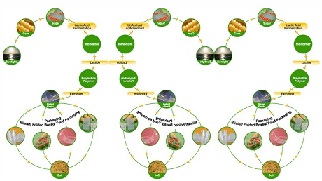

Shifting from petrochemical feedstocks to renewable resources—making plastics from plants—can also rectify some environmental challenges associated with petrochemical extraction and render plastics production sustainable (see the figure).

A nearly inexhaustible supply of annually renewable carbon is embedded in plant-derived macromolecules (including cellulose, lignin, and other polysaccharides) and small molecules (including sugars, vegetable oils, and terpenes).

Carbon dioxide is also overly abundant. From these renewable feedstocks, it is possible to prepare nearly all of today’s polymers.

From a chemistry perspective, the main challenge is to establish efficient and commercially competitive transformations of these abundant resources into the set of compounds that are useful for plastics, elastomers, coatings, thermosets, and other polymeric materials. Efficiency is crucial because large-scale commodity chemicals must be produced for a few dollars per kilogram.

And although the chemistries already exist, most current processes and technologies that use biobased feedstocks are too expensive to be competitive with traditional petrochemical refining. This needs to change for the polymer industry to become truly sustainable.

Biobased Commodity Polymers

Two major approaches highlight the importance in chemistry to moving toward polymers made from renewable resources.

The first is focused on generating, from biobased resources, the small set of monomers used to produce the commodity polymers that dominate the polymer industry (see the figure).

Consider the fermentation of sugar to make ethanol, a process carried out in the United States at a scale of billions of kilograms every year (see the photo), for use in transportation fuels.

A commercially viable process is available for dehydrating this bioethanol to make bioethylene, which can be polymerized to produce a whole family of polyethylenes, the most abundant class of synthetic polymers (6).

Isoprene—the precursor to polyisoprene, a principal ingredient in car tires—can also be produced through catalytic conversion of fermentation products derived from sugar in processes that have commercial potential (7).

Some manufacturers are using ethylene glycol from bioethylene as a component in polyethylene terephthalate (PET), the polymer found in hundreds of billions of beverage bottles globally produced per year.

Efforts are also under way to produce other key high-volume monomers used in commodity polymers—propylene, styrene, and terephthalic acid—from plant-based materials (8).