Mechanical recycling – India’s rPET market is experiencing a remarkable surge, revolutionizing sustainability practices 23-02-2024

Mechanical recycling

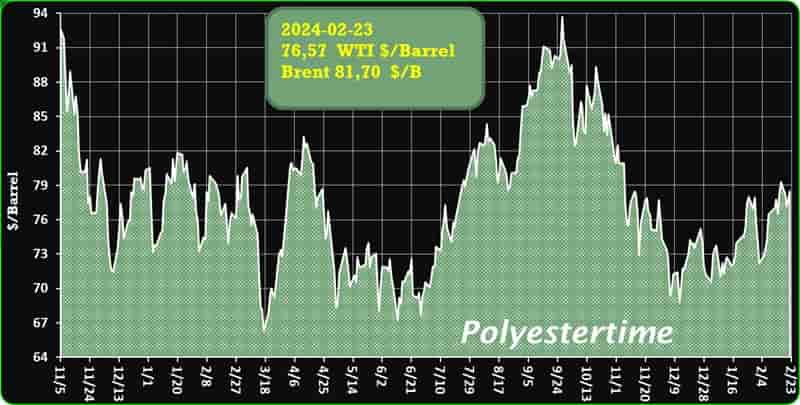

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

POSCO and ADNOC collaborate to establish clean hydrogen connections

POSCO Holdings of South Korea, along with its subsidiary POSCO International, and the Abu Dhabi National Oil Company (ADNOC) from the UAE, have inked a strategic cooperation agreement (SCA) to jointly explore the realm of clean hydrogen production. The agreement outlines a collaborative effort aimed at advancing the production and distribution of hydrogen utilizing LNG (liquefied natural gas) and CCS (carbon capture and storage) technologies, effectively capturing and storing carbon emissions generated during the hydrogen production process. Mechanical recycling

Under the terms of the agreement, the trio will spearhead the establishment of hydrogen production infrastructure at POSCO’s Gwangyang LNG terminal.

Commencing in 2029, the produced hydrogen will be channeled to meet various demands, including those of Gwangyang Steelworks and neighboring areas such as Hadong and Yeosu.

POSCO emphasizes the incorporation of CCS technologies, asserting that carbon emission reduction through the capture of incidental carbon during hydrogen production is crucial for achieving the status of clean hydrogen. Mechanical recycling

Beginning this year, the three entities plan to conduct a comprehensive feasibility study encompassing the establishment of clean hydrogen production facilities, as well as carbon dioxide capture and liquefaction terminals.

Lee Jun-Hyuk, Head of Energy Division at POSCO International, underscores the strategic significance of Gwangyang as a focal point for POSCO’s energy endeavors. He envisions the Gwangyang LNG terminal evolving into a pivotal hub for clean hydrogen production, thus bolstering Korea’s hydrogen industry development. Mechanical recycling

In parallel, POSCO is exploring additional avenues for sustainable energy solutions. In 2023, the company disclosed plans for a potential joint venture with U.S.-based CF Industries Holdings to construct a low-carbon clean ammonia plant at CF Industries’ Blue Point Complex in Louisiana. This initiative aligns with POSCO’s commitment to decarbonize its operations, with ambitions to import low-carbon clean ammonia to support the transition away from coal-based power generation.

Furthermore, POSCO aims to leverage low-carbon clean ammonia as a precursor for hydrogen production, facilitating its utilization in both gas-based power generation and steelmaking processes. Mechanical recycling

India’s rPET market is experiencing a remarkable surge, revolutionizing sustainability practices

As discarded PET bottles embark on a transformative journey toward greener solutions, they re-emerge as part of new products, contributing to a more eco-friendly planet. Let’s delve into the heartbeat of India’s rPET revolution and explore the challenges and opportunities in this transformative journey.

The Vibrant rPET Market in India Driven by environmental consciousness and supportive regulations, India is at the forefront of a recycling revolution. The demand for recycled PET (rPET) bottles is soaring, with urban centers like Maharashtra, Gujarat, Tamil Nadu, and Karnataka leading the charge. Sustainability isn’t just a moral imperative; it’s an economic choice. These regions’ waste management infrastructure forms the backbone of the burgeoning rPET market. Mechanical recycling

Innovations and Scope Businesses, including industry giants like Reliance Industries and Indorama Synthetics, are capitalizing on this opportunity. They’re pushing the boundaries of rPET applications beyond the conventional. From fibers and sheets to trays and even bottle-to-bottle recycling, the possibilities are boundless. This mirrors the global trend toward sustainable practices, emphasizing circular economies and responsible resource utilization.

Challenges Ahead Despite the promising landscape, challenges persist. Efficient collection infrastructure remains a priority, ensuring PET bottles reach recycling facilities effectively. Mechanical recycling

Contamination remains an ongoing issue, threatening the purity of recycled PET. Overcoming these hurdles is essential for sustained growth and a greener future.

India’s rPET journey is a beacon of hope, where innovation and sustainability intersect, paving the way for a more environmentally conscious tomorrow12.

LyondellBasell has revealed its recent acquisition of mechanical recycling assets, including rigid plastics recycling processing lines, from PreZero, a prominent global leader in recycling and waste management services

The acquisition encompasses the leasing of a processing facility located in Jurupa Valley, California, boasting a robust production capacity of approximately 50 million pounds annually for recycled materials.

Yvonne van der Laan, Executive Vice President of Circular and Low Carbon Solutions at LyondellBasell, emphasized the significance of this move, stating, “This acquisition further strengthens our U.S. presence and will deliver value for our customers and plastic recycling rates in the West Coast.” She highlighted the company’s commitment to leveraging its extensive experience in plastic recycling from Europe to establish a cutting-edge mechanical recycling facility to cater to the escalating demand for recycled products in the United States. Mechanical recycling

LyondellBasell intends to utilize its newly acquired mechanical recycling plant in California to produce post-consumer recycled resins utilizing plastic waste as feedstock. These recycled polymers will be marketed under the CirculenRecover brand, a key component of the company’s Circulen product portfolio designed to foster the circular economy. Operations at the new facility are slated to commence in 2025.

This strategic transaction aligns with LyondellBasell’s overarching goals of fostering a circular economy for plastics, mitigating plastic pollution, and meeting the rising consumer demand for sustainable products. Coupled with its previous investments such as the equity stake in the Cyclyx joint venture and the Cyclyx Circularity Center in Houston, this latest venture in California further solidifies LYB’s position in the competitive U.S. recycled products market. Mechanical recycling

Oerlikon solutions at Techtextil 24

Meeting high standards for airbags, seat belts, geotextiles and filter media.

Solutions for the automotive industry, geotextiles and filtration will be among end-use applications highlighted by Oerlikon Polymer Processing Solutions at this year’s Techtextil in Frankfurt from April 23 to 26.

The company reports that in today’s modern passenger cars an average of 30-35 kg of yarn is employed to ensure safety and comfort via products such as airbags.

Airbags have traditionally been made from polyamide but due to the ever increasing variety of airbag applications and the ever growing size of the systems, polyester is also often used today, depending on application requirements and cost/benefit considerations.

“Yarns produced with Oerlikon Barmag technologies meet all the high quality standards for airbags which must guarantee maximum safety for the occupants, and without any loss of function in any climate, anywhere in the world, for the entire service life of the vehicle,” says Dr Jen Supra, Oerlikon Barmag’s technology manager for technical yarns.

“Seat belts also play a life-saving role in vehicles. Mechanical recycling

They must be able to withstand tensile forces of more than three tons and at the same time stretch in a controlled manner in an emergency to reduce the load in the event of a collision.”

A seat belt consists of around 300 high-strength filament yarns spun from around 100 single filaments.

Oerlikon Barmag’s patented Single Filament Layer technology ensures a high tenacity (HT) yarn process that is as sophisticated as it is gentle. Mechanical recycling

Precision Textiles Unveils “PRESERVING The PLANET” Initiative

Precision Textiles — a supplier for the bedding, home furnishings, automotive and healthcare industries — is charting a course toward environmental sustainability with its “PRESERVING the PLANET” initiative. Committed to fostering a mindset that conveys “manufacturing with a conscience,” Precision Textiles is at the forefront of a transformative movement within the manufacturing sector. This strategic initiative underscores the company’s dedication to environmental stewardship and providing not only sustainable products but a commitment to contribute significantly to the global effort to safeguard the planet. Mechanical recycling

Precision Textile’s PRESERVING the PLANET initiative includes an all-encompassing strategy that incorporates key elements into every product produced including: FR solution products that offer the highest quality and performance standards that meet all government regulations; safety for its workers, its customers and the consumer; more natural materials such as cotton, wool and rayon derived from wood pulp; recycled or repurposed materials; certified sustainable materials that follow policies and processes for replanting, replenishment and regrowing; and a reduction in the company’s carbon footprint.

“As stewards of the environment, we are pleased to introduce our Preserving the Planet initiative,” said Scott Tesser, CEO of Precision Textiles. “Sustainability has long been our mantra and it is what drives our commitment to reducing our carbon footprint and embracing ecofriendly products and practices. Not only has it become fundamental to everything we do but it has evolved into a movement that is now encapsulated in our ‘Preserving the Planet’ initiative.” Mechanical recycling

Ascend to increase prices on nylon polymers, compounds and monomers

Ascend Performance Materials, the largest fully integrated producer of nylon 6,6, announced global price increases on its polyamide polymers, compounds and monomers, where contracts allow, as follows:

|

Material |

Price Increase |

|

|

Neat PA66 polymer |

$0.30/kg |

€0.28/kg |

|

PA6 and PA66 compounds |

$0.30/kg |

€0.28/kg |

|

Hexamethylene diamine |

$0.30/kg |

€0.28/kg |

These price increases will take effect Mar. 1, 2024. Customers should contact their sales representative for additional information. Mechanical recycling

About Ascend Performance Materials

Ascend Performance Materials makes high-performance materials for everyday essentials and new technologies. Our focus is on improving quality of life and inspiring a better tomorrow through innovation.

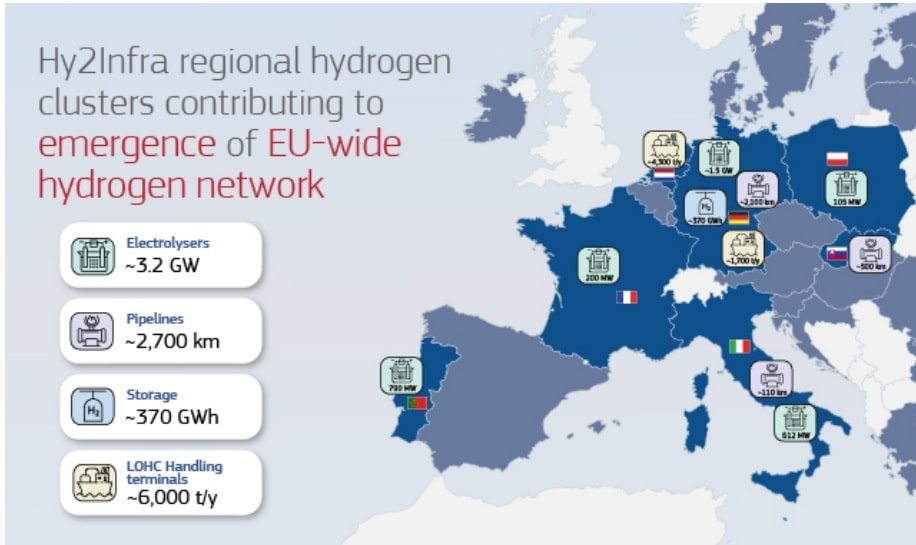

Commission approves up to €6.9 billion of State aid by seven Member States for the third Important Project of Common European Interest in the hydrogen value chain

The Commission has approved, under EU State aid rules, a third Important Project of Common European Interest (‘IPCEI’) to support hydrogen infrastructure. This IPCEI is expected to boost the supply of renewable hydrogen, thereby reducing dependency on natural gas and helping to achieve the objectives of the European Green Deal and the REPowerEU Plan. Mechanical recycling

The project, called “IPCEI Hy2Infra”, was jointly prepared and notified by seven Member States: France, Germany, Italy, the Netherlands, Poland, Portugal, and Slovakia. The Member States will provide up to €6.9 billion in public funding, which is expected to unlock €5.4 billion in private investments.

As part of this IPCEI, 32 companies with activities in one or more Member States, including small and medium-sized enterprises (‘SMEs’), will participate in 33 projects.

IPCEI Hy2Infra will cover a wide part of the hydrogen value chain by supporting:

- the deployment of 3.2 GW of large-scale electrolysers to produce renewable hydrogen;

- the deployment of new and repurposed hydrogen transmission and distribution pipelines of approximately 2,700 km; Mechanical recycling

- the development of large-scale hydrogen storage facilities with capacity of at least 370 GWh; and

- the construction of handling terminals and related port infrastructure for liquid organic hydrogen carriers (‘LOHC’) to handle 6,000 tonnes of hydrogen a year.

and facilitate future market integration.

The IPCEI will support the gradual emergence of an EU-wide hydrogen infrastructure starting from different regional clusters. Mechanical recycling

Mechanical recycling