Biopolymers Petrochemicals RecycledWaste 01-07-2021 - Arhive

Biopolymers Petrochemicals RecycledWaste

Crude Oil Prices Trend

-RadiciGroup overcomes the pandemic

In the 2020 fiscal year, a contained drop in turnover to -6.7% and growing margins for the Bergamo chemical group. 2021 started with growing results.

RadiciGroup, an important Bergamo-based company in chemistry, technopolymers, fibers and nonwovens, presented the financial results for the year 2020, considered satisfactory by the management considering the difficulties and challenges imposed by the Covid-19 pandemic.

If the consolidated turnover showed a drop of -6.7% to 1,019 million euros, the gross operating margin (Ebitda) increased last year by + 4.4% to 173 million euros and the operating profit , net of amortization, depreciation and write-downs, it stood at 87 million euros, or + 8.1% compared to 2019. This is also due to the stability of volumes against an improvement in margins, thanks to higher prices starting from second half of the year.

Investments have also been confirmed, amounting to 50 million euros for the year, for technological upgrading and plant flexibility, as well as for the sustainability of processes and products.

In 2020 – reads a note from the Bergamo group – the financial trend followed the developments of the spread of the pandemic, recording a sharp drop in demand during the first part of the year, after the introduction of lockdown measures, followed by a moderate recovery between September and November, partially slowed down by the resumption of infections in December.

2021 began with positive results: in the first quarter turnover and EBITDA grew in almost all business sectors, despite the sharp increase in raw material costs recorded in the period.

“2020 was certainly a complex year from various points of view – comments Angelo Radici, President of RadiciGroup -, but we were able to limit the negative impact of the pandemic and achieve satisfactory results that confirm our competitiveness on the market. The new year opens with the challenge of being able to fully grasp the potential of the recovery of economic activities and, despite a still uncertain global scenario, we are confident that, by leveraging our solidity and efficiency and focusing on productions with greater added value, on better flexibility production and investments in research and development, we will be able to continue to offer our customers highly performing solutions, working together on increasingly innovative and sustainable projects “.

-Plastics Industry Must Speak with United Voice to Counter Anti-Plastics Messaging

At Virtual Engineering Days, Plastics Industry Association President and CEO Tony Radoszewski urged industry to “push back” against those who want to “put us out of business.” Biopolymers Petrochemicals RecycledWaste

Plastics Industry Association (PLASTICS) President and CEO Tony Radoszewski didn’t mince words during a presentation at Virtual Engineering Days this week. The plastics industry has a “target on its back,” he told attendees. “Some people are trying to put us out of business,” and industry has to push back with a “united voice,” he stressed. Radoszewski showed how on day one of the three-day virtual event. He was joined by PLASTICS Chief Economist Perc Pineda, who delivered an upbeat economic assessment of the industry in a post-pandemic landscape.

Preaching to the choir to some extent, Radoszewski highlighted the many ways that plastics benefit society. The litany is familiar to those of us who cover the industry, but it bears repeating that polymers enable medical breakthroughs and improve patient safety, increase fuel efficiency in automobiles through lightweighting, reduce food waste and make food last longer thanks to innovations in packaging, and help build a more durable, sustainable infrastructure. None of that seems to drown out the clarion call of NGOs and parts of the media to abolish plastics. Radoszewski acknowledged the dissonance — “We are part of the problem because there is so much plastic” — but, importantly, “we’re also part of the solution.”

-SIBUR launches Vivilen brand of products containing recycled waste

SIBUR, Russia’s largest integrated petrochemicals company and a leader in sustainable development, is introducing the Vivilen brand that will see recycled materials incorporated into its production process, said the company on its site.

The brand manufactures polypropylene (PP) and polyethylene (PE) utilising partners’ capacities. In the future, the product line will be expanded with polyethylene terephthalate (PET) and other products. Biopolymers Petrochemicals RecycledWaste

New polymer grades were developed by SIBUR’s R&D Polylab facility and tested by processing companies. SIBUR has already started to supply new solutions on an industrial scale and is going to ramp up its output going forward into 2H 2021.

Promoting circular economy and developing polymer recycling are essential focus areas of SIBUR’s Sustainable Development Strategy.

Secondary polymers have a great recycling potential and can be reused up to ten times or more. When used to manufacture end products, they help reduce the environmental footprint: by 2050, recycling of the world’s polymer waste will cut down GHG emissions by 1.6 bt.

-Schur Flexibles acquires Italian film manufacturer Termoplast

Schur Flexibles Group has acquired film producer Termoplast in a move to accelerate its expansion in the Italian market.

Based in Tuscany, Italy, Termoplast is a manufacturer of films for industrial, food, medical and pharmaceutical applications, and specialises in recyclable products. The company’s portfolio includes sealable, barrier and high-barrier films, as well as peelable and reclosable offerings. Biopolymers Petrochemicals RecycledWaste

With a manufacturing facility in Gambassi Terme, Florence, the family business reported annual revenue of approximately €50 million in 2020.

The company is said to pursue a holistic resource efficiency approach. All waste from Termoplast’s production operations is recycled, while plastic waste from the region is also prepared for further processing by Termoplast’s own recycling company.

Schur Flexibles CEO, Michael Schernthaner, said: “Termoplast is a perfect fit for Schur Flexibles Group. Its entire production process is geared towards sustainability. It is truly a best practice example of the circular economy, whether with respect to innovations, its product portfolio, the recycling of post-industrial waste.

-International Recycling Week: Informal census finds consensus

Collectors and reprocessors of plastic scrap and end users of the material all see intense activity in the sector.

A panel gathered for the online International Recycling Week event represented several links in the plastic recycling supply chain, and each one of them is involved in and/or witnessing big-ticket investments in new plastic recycling activity.

Mass media headlines surrounding plastic packaging have been consistently negative for several years, as improperly discarded plastic has accumulated in the ocean and other ecosystems. The activism has spurred (belatedly, activists would likely contend) new regulations and substantial investments by brand owners, plastics producers, waste and recycling companies and entrepreneurs all seeking to raise the global packaging recycling rate. Biopolymers Petrochemicals RecycledWaste

Syed Shahzad Alam, a procurement manager in the Middle East region for Unilever, pointed to that company’s aggressive plastic recycling targets when commenting, “We are not the only one doing this, but we are certainly the pioneer and we are helping to create an industrywide drive, [and] this is actually happening.”

France-based waste and recycling firm Veolia has “heavily investing in plastic recycling,” said Ronald Richa, who works for the firm in the United Arab Emirates (UAE). Richa says his work involves “structuring the plastics recycling business here with a new project we intend to build [focused on] polyethylene terephthalate (PET) recycling.”

-Brief analysis over the trade barriers China PET bottle chip industry faces

We are to update the latest overseas trade barriers condition Chinese PET bottle chip plants face.

US and Japan anti-dumping duty on Chinese PET resin is to due in 2021-2022. US began to levy 126-162% extra tariff on Chinese PET resin since May 2016. Apr 2021, US International Trade Commission (ITC) launched the first anti-dumping and countervailing sunset review, and the preliminary results of this investigation may come out at the end of 2021. Biopolymers Petrochemicals RecycledWaste

PET bottle chip exports to US reached its highest in 2014, which was around 150kt. However, in view of the current relationship between China and US, we believe that the chance of directly abolishing anti-dumping countervailing duties is small, but it may also be good if we can get the result of tariff reduction year by year.

Japan began to collect 39.8%—53% anti-dumping duties since Dec 28 2017, duration 5 years. So around the end of 2022, Japan’s anti-dumping duties on Chinese PET bottle chip will expire.

Japan’s imports of PET bottle chip from Chinese mainland peaked at 440kt in 2016.As a net importer, Japan has small capacity which cannot meet domestic consumption demand. Its annual import volume is basically around 900-1000kt. After levying ADD on Chinese materials, the local downstream factories in Japan directly bear the consequences of high pricing.

-TAIF plans to increase polypropylene production capacity at meringue NKNKh

TAIF plans to increase its polypropylene production capacity, Realnoe Vremya reports.

Nizhnekamskneftekhim (part of TAIF Group) plans to build a new polypropylene plant with a design capacity of 400,000 tonnes of products per year in the near future. A tender has already been announced, and companies-applicants for the contract from Europe, Korea, Japan and China are competing in whose offer will be the best in terms of the combination of price and quality of performance. Business negotiations with the management of the Chinese corporation China Machinery Engineering Corporation (CMEC) and its business partner China Huanqiu Contracting & Engineering Corporation (HQC) took place the other day.

The management of TAIF PSC and Nizhnekamskneftekhim met with the top managers of CMEC Corporation and HQC Company, applying for a contract for the construction of PP-400. Biopolymers Petrochemicals RecycledWaste

It is noted that Nizhnekamskneftekhim is already one of the leaders in the Russian Federation in this segment with a design capacity of the existing polypropylene production of 180,000 tonnes and a real production of 215,000 tonnes per year. Taking into account the existing plant and the one that is planned to be built – with a design capacity of 400,000 tonnes – Nizhnekamskneftekhim will almost triple the production of polypropylene and become one of the largest and most powerful producers of polypropylene in Europe.

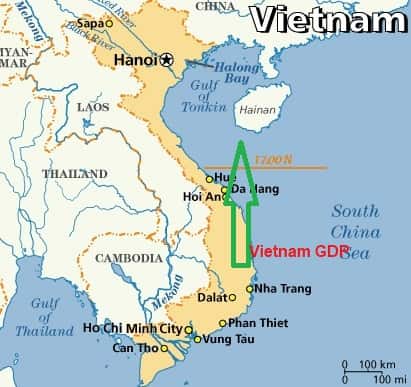

-Vietnam GDP growth accelerates in Q2 on strong industry output

Vietnam’s economic expansion accelerated in the second quarter on an annualized basis, backed by strong performance from the manufacturing sector.

June-quarter GDP growth at 6.61% represents a sharp improvement from the 0.39% pace recorded in the same period last year, and higher than the 4.65% rate registered in the first three months of 2021, official data showed on Tuesday.

Analysts were expecting a higher growth of 7.20% in the June quarter, Singapore-based UOB Global Economics and Markets Research said in a note on 29 June.

In the first half of 2021, GDP growth was 5.64% compared with a 1.82% growth recorded in the previous corresponding period, according to data from the Government Statistics Office (GSO) of Vietnam. Biopolymers Petrochemicals RecycledWaste

-Trendy new colouring for home-compostable biopolymers

The Lifocolor group has announced that it has expanded its range of Lifocolor BIO masterbatches for biopolymers, with what the company calls bio-C colour concentrates. These concentrates are based on a selection of particularly environmentally compatible colourants and are suitable for colouring bio-based home compostable polymers. Biopolymers Petrochemicals RecycledWaste

Under home composting conditions, they degrade to water, carbon dioxide and minerals.

Now, for the first time, Lifocolor has designed its trending colour series 2022 according to the standards of bio-C masterbatches, demonstrating that bio-based and biodegradable bioplastics can be both trendy and colorful as well as highly sustainable.

“Combined with suitable biopolymers, our Lifocolor Bio-C Masterbatches can decompose under home composting conditions. They decompose during the decomposition process to water, carbon dioxide and minerals. All the colourants used are therefore selected so that they do not pollute the environment during degradation,” said Dr. Martin Fabian, Managing Director of the Lifocolor corporate group.

This year, the Lifocolor group has gone a step further with its interpretation of the trending plastic colours for 2022.

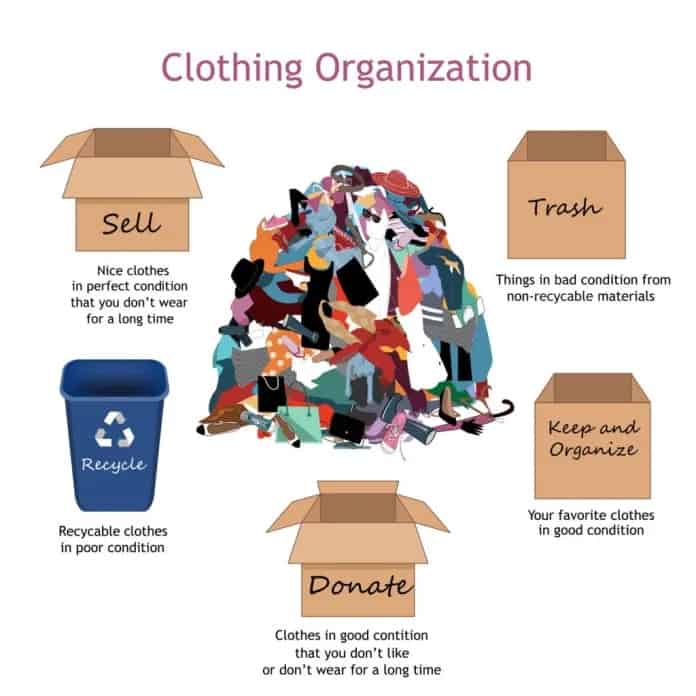

-Circular economy in textile industry- the new way forward

Today, we will be talking about an industry that is currently resulting to be very beneficial for any economy. It generates foreign direct investments as well as absorbs a large share of the labor force in any country. Yes, the textile industry. The global textile market is very vast. Biopolymers Petrochemicals RecycledWaste

It sums up to nearly $1.4 trillion and its major share is in the developing countries, like China, India, Bangladesh, Brazil, Pakistan, and Turkey. The textile industry employs a large number of people, nearly over 300 million people, therefore, contributing to reducing unemployment in the country.

Being a huge industry, the production levels are very high. However, so are its implications on the environment. Often the people involved in the production process do not realize the harm they are causing to the environment. From non-environment-friendly methods of production to improper disposal of waste, the list is a long one. To meet the rising demand for textiles, these environmental and social values are often neglected and this continued negligence has been very dangerous for the world, harming the people and over-filling the landfills. The world has started to realize the damage it is doing to the environment through its non-eco-friendly measures. A point to keep in mind is that this not only creates environmental problems but also leads to losing many economic opportunities.

Biopolymers Petrochemicals RecycledWaste