EU legislators agree on Ecodesign rules, but fail to ban the destruction of unsold goods and ensure enforcement for products sold online.

The European Commission, Parliament and Council reached an agreement last night on a new framework to make products sustainable by design. The European Environmental Bureau (EEB) welcomes the ban on the destruction of unsold textiles as well as progressive provisions on cement and substances of concern, but lament the twofold failure to rule out the wasteful destruction of unsold electronics and provide a credible enforcement regime for products sold online. Man-made yarns

The Ecodesign for Sustainable Products Regulation (ESPR) is one of the flagship initiatives of the Green Deal and Europe’s circular economy objectives. The policy is a revamp and extension of the existing Ecodesign and energy labelling framework, which only applies to electrical appliances.

The new regulation will put in place minimum requirements such as efficiency, durability and recyclability for almost any product on the EU market. However, during the negotiations, some products such as military equipment and motor vehicles were removed from the scope.

The regulation includes provisions to ensure the traceability of harmful substances in products, and the possibility to restrict them when they are a barrier to recycling or have a negative impact on human health. Man-made yarns

More…

In a noteworthy development, Trinseo, a major player in the polystyrene market, is implementing a significant reduction in the prices of polystyrene across Europe for the month of December

The company, known for its diverse range of polystyrene grades, is strategically revising its pricing strategy by lowering costs for all grades of polystyrene intended for general use (GPPS) and crystal applications (HIPS). This price adjustment spans across popular brands such as Styron, Styron A-Tech, and C-Tech. Man-made yarns

Trinseo has communicated that the reduction in prices amounts to a substantial 90 euros per ton. This move is indicative of the company’s commitment to maintaining competitive pricing and adapting to market dynamics. Notably, this marks the second consecutive reduction in prices, following a previous cut of 125 euros per ton announced in November. The successive nature of these adjustments underscores the company’s responsiveness to market trends and its proactive approach in managing pricing structures.

The impact of this price drop extends across the entire spectrum of polystyrene grades, emphasizing Trinseo’s broad commitment to providing cost-effective solutions for various applications.

The affected grades include those catering to general use (GPPS) as well as crystal grades (HIPS). The price cut applies uniformly to products marketed under well-known brands such as Styron, Styron A-Tech, and C-Tech, further emphasizing the comprehensive nature of this strategic pricing move. Man-made yarns

Trinseo’s decision to implement these price reductions aligns with the company’s objective of enhancing competitiveness, fostering market accessibility, and maintaining a dynamic response to evolving economic conditions. The consecutive reductions in November and December showcase Trinseo’s agility in navigating market fluctuations and its dedication to delivering value to its customers in the polystyrene segment.

Kumho Tire chooses Synthos as one of its key partners for sustainable development and seals the partnership during a ceremony in South Korea.

Synthos, a leading global producer of synthetic rubber, has announced the signing of a Memorandum of Understanding (MOU) with Kumho Tire, a leading South Korean tire manufacturer, for the joint development of sustainable tire raw materials.

Under the MOU, the two companies will conduct a joint research and development project for Neodymium-Butadiene rubber using Bio-Butadiene and expand the use of environmentally friendly synthetic rubber in tire manufacturing.

Dr. Malte Wohlfahrt, R&D Director, Synthos Synthetic Rubber, emphasized the importance of collaboration in the research and development of sustainable rubber and tire materials. “We are very pleased to be selected as one of Kumho Tire’s key partners to strengthen its efforts to develop environmentally friendly tires. Man-made yarns

We strongly believe that we have the best chance to contribute to net zero mobility if we can work together with industry leaders like Kumho Tire, who has already produced tires made from 55% sustainable raw materials in 2022 and is currently developing tires made from 80% sustainable raw materials that will be launched by the end of 2023. Kumho Tire’s impressive experience in developing tires with a lower carbon footprint combined with Synthos’ extensive expertise in sustainable synthetic rubber will enable further carbon footprint reduction towards our shared goal of carbon neutrality by 2050.”

More…

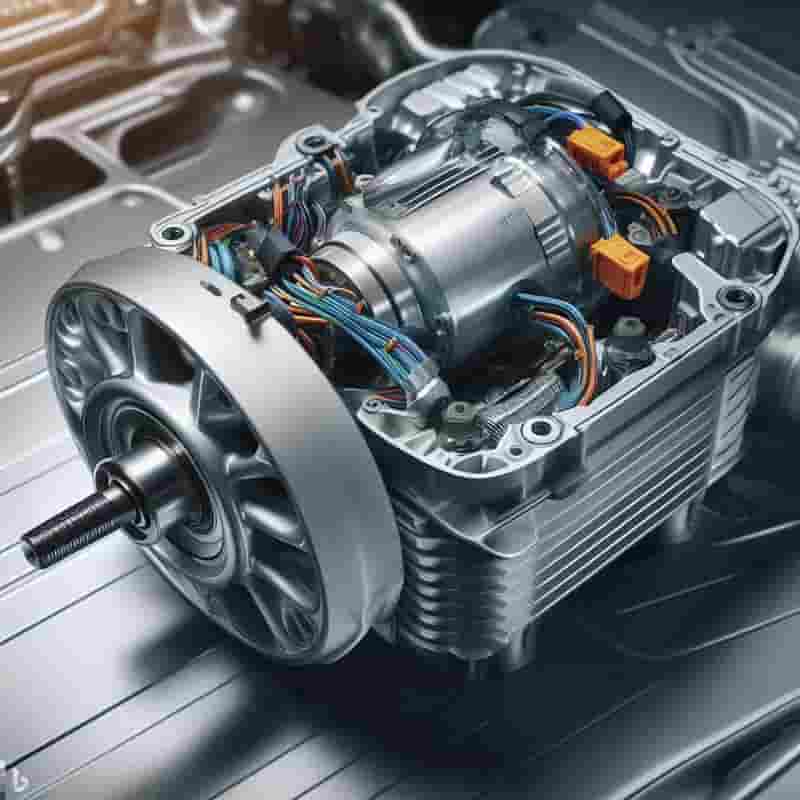

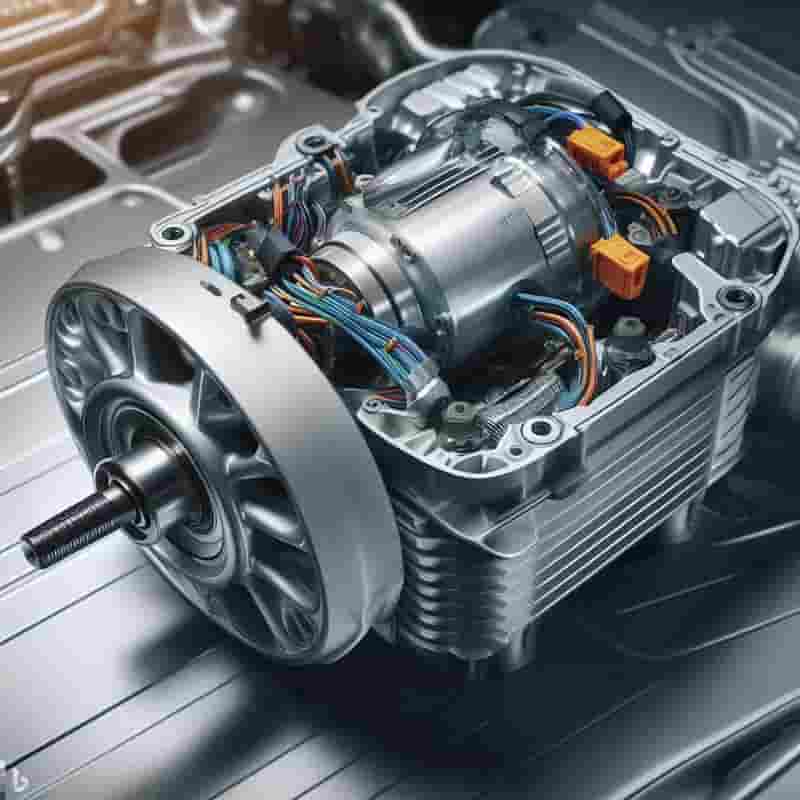

Critical raw materials? In an electric car you need 207 kilos

A comprehensive study conducted by Intesa Sanpaolo, as presented in the ‘Med & Italian Energy Report 2023,’ sheds light on the weighty matter of minerals required for this paradigm shift. The study not only emphasizes the quantities involved but also addresses the geographical concentration of crucial minerals, highlighting potential challenges for Europe. Man-made yarns

The sheer weight of the matter is evident in the fact that an electric car necessitates an average of 207 kilograms of diverse minerals, such as graphite, copper, cobalt, nickel, rare earths, lithium, and manganese. This stands in stark contrast to the 33.6 kilograms required for a traditional internal combustion engine vehicle, marking a sixfold increase. The report, presented to the European Parliament by the SRM study center linked to the Intesa Sanpaolo group, underscores the significance of CRM in the transition.

The distinction between critical raw materials and rare earths is pivotal in the study. While rare earths like Scandium, Yttrium, and Lanthanum find marginal use in the automotive sector, the primary focus is on critical raw materials. Solar photovoltaics, wind turbines, lithium-ion batteries, and electric motors are also examined for their mineral requirements. For instance, offshore wind turbines demand nine times more CRM than a conventional gas plant. Man-made yarns

Director General of the SRM, Massimo Deandreis, raises concerns about the territorial concentration of key minerals, such as lithium, cobalt, copper, and rare earths. He emphasizes that Europe’s reliance on specific regions exposes the European Union to geopolitical risks, necessitating strategic planning to mitigate these challenges.

The report elucidates the global distribution of these critical minerals, with significant shares located in countries like Congo, Australia, China, and South Africa. The Mediterranean region, including European countries, is notably deficient in these resources, except for Morocco, which ranks among the top three global producers of phosphorus. Man-made yarns

In response to these challenges, the European Union has proposed the Critical Raw Materials Act in 2023. This legislative framework aims to secure a safe and sustainable supply of critical raw materials, outlining objectives such as 10% of annual EU consumption covered by internal extraction, 40% by internal processing, 15% by internal recycling, and a cap of 65% covered by a single third country. As Europe strives to meet its 2050 objectives, the study underscores the imperative of addressing CRM dependencies for a successful energy transition.

This regulation aims to make products more durable, reusable, upgradable, reparable, recyclable, and easier to maintain. It targets a range of products including textiles and footwear and intermediate products. Man-made yarns

EuRIC, the voice of Europe’s recycling industries, welcomes the agreement, which incorporated most of the recycling industries’ main points, such as the compliance of online marketplaces with EU legislation, the requirement for transparency in reporting the destruction of unsold goods, and the introduction of the “Digital Product Passport”.

However, we regret the fact that the imposed direct ban on the destruction of unsold textiles and footwear fails to consider the role of recycling. Ending the take-make-waste cycle (linear economy model) is a significant step towards circularity but is impossible without recycling operations.

To equate recycling with destruction contradicts the very objectives of the Circular Economy Action Plan. The path to circularity should be defined by recycling operations, providing a second life to materials. Man-made yarns

Recycling is not destruction, but a resource recovery process, crucial for extending the lifecycle of materials.

Therefore, we strongly urge lawmakers to correct this miscalculated oversight and include recycling as a possibility to treat unsold goods, whenever reuse is not possible.

More…

Sustainable fuel – Innovative bio-based aromatics pave the way for 100% sustainable aviation fuel 07-12-2023

Man-made yarns