Petrochemical MEG CircularEconomy Textile 11-12-2020 - Arhive

Petrochemical MEG CircularEconomy Textile

Crude Oil Prices Trend

-Lanxess raises 1,6-hexanediol prices

Lanxess has raised its prices globally for 1,6-hexanediol (HDO) with immediate effect (from 4 December), due to a significant increase in raw material costs in recent months, reported Chemweek with reference to the company’s statement.

The product price has been hiked by EUR350/metric ton (USD425/metric ton). HDO is an important precursor for high performance coatings, fibers, adhesives, polyurethanes, polycarbonate diols, and as a reactive diluent for epoxy resins.

The company raised its prices worldwide on 1 December for adipic acid by EUR90/metric ton for the same stated reason. Adipic acid is used in the production of polyamide (PA) 66–based fibers and polymers, and for the synthesis of polyester polyols for polyurethane systems and thermoplastic polyurethanes.

As MRC informed earlier, since January 2020, Vinmar Polymers America has been distributing Lanxess Corp.’s high-performance plastics to customers in North America.

We remind that Russia’s output of chemical products rose in October 2020 by 7.2% year on year. At the same time, production of basic chemicals grew in the first ten months of 2020 by 6.3% year on year, according to Rosstat’s data. According to the Federal State Statistics Service of the Russian Federation, polymers in primary form accounted for the greatest increase in the January-October output. October production of polymers in primary form grew to 857,000 tonnes from 852,000 tonnes in September. Overall output of polymers in primary form totalled 8,340,000 tonnes over the stated period, up by 17% year on year.

-Brexit: EU unveils fresh emergency ‘no deal’ plans

Talks between the UK and the EU have failed to find an agreement. There are just three weeks to go until the Brexit transition phase is scheduled to end.

The European Commission on Thursday unveiled no deal Brexit plans in a bid to limit travel disruption after talks between British and EU leaders failed to break an impasse.

Officials said both sides should offer reciprocal access to their fishing waters for up to a year, potentially easing tension around one of the most emotive sticking points in the trade negotiations.

Britain told the EU earlier it should make significant concessions to break the deadlock by the end of the weekend for clarity about the finale to the five-year-old Brexit crisis.

Both sides gave themselves until Sunday to decide whether to continue talks or allow the UK to leave the current Brexit transition period without a free trade agreement.

“Negotiations are still ongoing but the end of the transition is near,” said Ursula von der Leyen, the European Commission president. “There is no guarantee that if and when an agreement is found it can enter into force on time.”

-Scientific committees: EU-wide restriction best way to reduce microplastic pollution

The Committee for Socio-economic Analysis (SEAC) has adopted its opinion on a landmark restriction proposal, which would ban microplastics in products such as cosmetics, detergents, fertilisers and could lead to a ban of its use as soft infill on artificial turf sports pitches. It would prevent the release of 500 000 tonnes of microplastics into the environment over 20 years. Petrochemical MEG CircularEconomy Textile

Helsinki, 9 December 2020 – The adoption of SEAC’s opinion follows an earlier opinion by the Committee for Risk Assessment (RAC) in June 2020. Both committees concluded that an EU-wide restriction under the EU’s chemicals legislation REACH is the most appropriate means to address the risks of billions of small, solid plastic particles polluting our environment. SEAC also concluded on the expected benefits and costs to society of the proposal.

Bjorn Hansen, ECHA’s Executive Director says: “We need to protect our environment from microplastic pollution, and this restriction proposal is the most comprehensive of its kind in the world. We have now concluded our scientific and technical assessment and given our recommendations on how to best address the risks. This will contribute to decision making in the European Commission and the aims of the EU’s Plastics Strategy.”

-Petkim Raises December LDPE Prices in Turkey Again

The Turkish polymer producer Petkim, whose controlling stake is Azerbaijani SOCAR, raised the selling prices of high-pressure polyethylene (LDPE) on December 3, market sources told ICIS . Petrochemical MEG CircularEconomy Textile

This is the second time this month that a Turkish manufacturer has raised its LDPE prices.

Thus, the prices for the company’s material on the terms of delivery of FCA Aliaga (Aliaga, Turkey) increased by USD100 per ton.

The company lists actual prices on a gross basis, and Petkim may offer large discounts on shipments.

Earlier it was noted that over the past month Petkim raised its LDPE prices four times, and the total increase amounted to USD190 per ton.

In addition, the company increased the December prices for polypropylene (PP) and polyethylene (HDPE) last week.

-The plastics cycle and contaminated recyclate

Contaminated recyclate used in manufacturing or processing plastics lowers product quality and can even damage machinery. The solution? Systems that reliably spot and correctly sort out contaminants from other materials.

Recyclate from used plastic is a valuable material that is used in manufacturing new products. Manufacturers and fabricators process it in flake, powder or granulate form, but only if the recyclate is of good quality. Different plastic types, incorrect colours or foreign objects can have a significant impact on recyclate quality. A distinction can be drawn between three main types of recyclate contamination: foreign plastics, discolouration and foreign objects. Petrochemical MEG CircularEconomy Textile

These contaminants can enter the processing cycle at almost any time. Even the plastic waste from collection systems, which is pressed into balls, contains an array of materials that don’t belong there. Recycling companies are required to carefully sort their plastic waste to safeguard the quality of their recyclates. Random samples suggest that contaminants could account for up to 80% of plastic waste.

-Resealable PE film lidding ‘M-ResinsTM’ by Bostik tested by RecyClass

The findings of an independent laboratory testing of ‘M-ResinsTM’ technology show that it is suitable for recycling in a polyethylene (PE) film stream. The analysis was carried out by Proplast, as per the RecyClass Recyclability Evaluation Protocol for PE films. The technology is a multilayer resealable film lidding which is generally used in combination with a stiff film. Petrochemical MEG CircularEconomy Textile

According to the laboratory results ‘M-ResinsTM’ technology conforms to the current European PE film recycling stream provided it is used under specific conditions[1]. Since the technology is destined to be applied within a packaging structure, this approval does not apply automatically to the final packaging product. Hence the full lidding structure must be tested to receive a product approval. Another precondition is the presumption that ‘M-ResinsTM’ does not exceed 10% of the whole European LDPE flexible film market share. In case this threshold is exceeded, further testing will be required, and the current approval will be subject to a review.

-MEG prices rise in Asia amid rising prices in the futures market

Monoethylene glycol (MEG) prices in Asia rose to their highest level in nine months on December 7, surpassing USD500 per tonne amid rising prices in the futures market, ICIS reported. Petrochemical MEG CircularEconomy Textile

Negotiations on spot quotations were conducted in the range of USD500-510 per tonne, CFR CMP (main ports of China), according to market sources.

Thus, a deal was made to ship a batch of material in early January next year at a price of USD502 per ton, CFR CMP.

According to ICIS, MEG spot prices were USD494-496 per tonne, CFR CMP on December 4.

On Monday morning, MEG futures in China rose nearly 3%, putting strong pressure on price negotiations in the spot market.

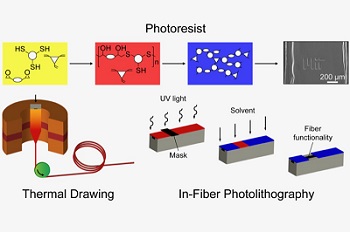

-UV-activated polymer for smart fabrics developed

E-textiles have progressed to e-fibers. The next means of incorporating functional elements may be in process, give the research into a new polymer that’s activated by UV light. As reported on newatlas.com, a team at MIT started by developing a photosensitive thiol-epoxy/thiol-ene polymer. When the material is exposed to ultraviolet light, its molecules crosslink with one another to form a network that’s impermeable to common solvents.Petrochemical MEG CircularEconomy Textile

The polymer was used to coat a conductive filament, which made an insulated fiber with a conductive core. Opaque masks were placed along the length of the fiber, after which it was exposed to UV light, so that some parts were exposed to the light and others were protected. When the fiber was subsequently treated with acetone solvent, the polymer only dissolved off the sections that had been shielded from the light.

-Polyester polymerization rate tends to reduce amid weaker seasonal demand

Stimulated by firm international crude oil and polyester feedstock futures market, downstream buyers replenished under low price. Therefore, sales of polyester fibers improved apparently. Actual trading price of PFY rose by around 300-400yuan/mt. Price of polyester fibers is expected to slightly move up driven by upstream cost and falling stocks but the increment may be limited amid weakening seasonal demand.

Operating rate of twisting units and fabric mills descended but was still higher than past years. Downstream orders diminished but were still flat with past years supported by orders for home textiles. However, seasonal demand tends to reduce later. End-user orders are supposed to fall and polyester polymerization rate tends to decrease.

Sales of grey fabric weakened further. Sales of high density polyester taffeta for down sweater were moderate in Wujiang and Siyang and those of other fabrics for apparels apparently diminished. Many enterprises reflected that sales of grey fabric were only 30-40%, and stocks kept accumulating. Orders for fabrics for spring and summer wear were sluggish. Petrochemical MEG CircularEconomy Textile

-LyondellBasell and SUEZ increase plastics recycling capacity

Companies expand their Quality Circular Polymers Joint Venture

LyondellBasell (NYSE: LYB) one of the world’s largest plastics, chemicals and refining companies and SUEZ (EPA: SEV), a world leader in environmental services, today jointly announced the acquisition of TIVACO, a plastics recycling company located in Blandain, Belgium. The company will become part of Quality Circular Polymers (QCP), the companies’ existing 50/50 plastics recycling joint venture. With this transaction, QCP will increase its production capacity for recycled materials to approximately 55,000 tonnes per year. Petrochemical MEG CircularEconomy Textile

“This latest investment in QCP supports LyondellBasell’s ambition to produce and market 2 million tons per year of recycled and renewable source-based polymers by 2030. Extending the plastics lifecycle through recovery, recycling and reuse not only eliminates waste but also produces a product with a lower CO2 footprint,” said Richard Roudeix, Senior Vice President Olefins & Polyolefins, Europe, LyondellBasell. “This innovative approach is key to unlocking additional value from existing plastics while addressing brand owners’ needs for sustainable products.”

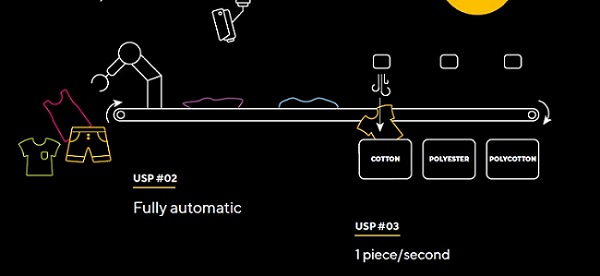

-Textile & Apparel Waste Management: Technology and its role!

Recycling of textiles and garments is important to drive circular economy concept and technology is the only way to do this. But, does the industry know the significance of the concept and the understanding of the available technologies? Let’s find out some key available technologies… Petrochemical MEG CircularEconomy Textile

The fact is that all sorts of clothes can be given a second life after consumers discard them, and not to mention, a second life to all discarded clothes is MUST to drive ‘circular economy’ concept. But, the question is – do we even bother to go deep into the subject and concept of recycling and align our efforts with the industry’s goals?

The previous feature named – “Textile & Apparel Waste Management: Concept, Adoption and Challenges” talked about the concept of recycling and how it’s taking shape in today’s apparel industry, while we have now brought forth the technologies available for the industry to boost recyclers’ endeavours towards strengthening circular economy concept…

Petrochemical MEG CircularEconomy Textile