Petrochemical PETBottle Recycling H2 01-12-2020 - Arhive

Petrochemical PETBottle Recycling H2

Crude Oil Prices Trend

-Michelin and Pyrowave join forces to industrialize an innovative plastic waste recycling technology

Pyrowave, a pioneer in the electrification of chemical processes and plastics recycling, and Michelin agree to industrialize an innovative plastic waste recycling technology

- Michelin Group and the Canadian firm Pyrowave join forces to accelerate time-to-market for an innovative plastic waste recycling technology.

- They agree to fast‑track the process industrialization.

- The purpose of the technology is to increase the rate of sustainable materials not only in Michelin tires, but also in other industries.

The Canadian firm Pyrowave proudly announces a joint development agreement with the Michelin Group. Through the Pyrowave‑developed technology, it is possible to generate recycled styrene from plastics found in packaging, insulation panels and/or household appliances. This recycled styrene is an important monomer*: it is used in the production of polystyrene and synthetic rubber for tires and a large number of consumer products.

-Germany’s BASF completes plant for plastic additives business in Italy

BASF on Monday announced the technical completion of a newly constructed plant for its plastic additives business in Pontecchio Marconi, Italy.

The state-of-the-art facility will deliver a wider range of BASF’s NOR solutions to support BASF’s position in the growing agriculture industry, it said in a statement.

BASF NOR technology platform consists of a range of light and thermal stabilizers that are especially effective in plasticulture applications such as greenhouse covers, macro and small tunnels, nettings and substrate bags.Petrochemical PETBottle Recycling H2

The BASF Pontecchio site has already been a major production unit for hindered amine light stabilizers.

-New sustainability standards for man-made cellulosic fibres establishes

Man-made fibres made from wood pulp and natural plant materials may hold the key to a truly circular fashion industry development, but the sustainable quality of the field can be further enhanced.

According to a report out last week from Forum for the Future and the Textile Exchange, man-made cellulosic fibres (MMCF) sector could revolutionize the wasteful textile and apparel sectors. Petrochemical PETBottle Recycling H2

MMCF includes materials such as lyocell, viscose, and modal that comprise roughly 7% of global fibre production which offers ‘unique prospects’ for achieving a circular fashion industry, the report said.

According to the Ellen MacArthur Foundation, without the quality loss, MCCF waste fibres can be turned into new fibres typically associated with recycling natural fibres. As a result, this fibre is apart from other materials coveted by the fashion industry, which wastes disposal is roughly $500bn in value every year due to the that is barely worn and rarely recycled.

-What is the real cost of green hydrogen?

What is the real cost of green hydrogen? Is there a reliable and straightforward way to obtain this cost? What information is needed? Is it valid to compare green hydrogen prices with grey or blue hydrogen prices? Mike Parr and Simon Minett attempt to answer these questions.Petrochemical PETBottle Recycling H2

Mike Parr is director of PWR, a UK-based company providing market research and technical support in the field of renewables and energy efficiency. Simon Minett is founder of Challoch-Energy, a consulting firm.

Green hydrogen is much in the news. In October Cap Gemini published a report called “Net Zero 2020”. Page 36 had a section on green hydrogen with the declaration “At around €6 per kg, green hydrogen is not competitive today with fossil energies (parity at €1/kg equivalent to €25/MWh)”.

Last week another hydrogen organisation announced itself “the Renewable Hydrogen Coalition” accompanied by (yet another) report on green hydrogen which contained (yet another) price estimate for green hydrogen – €6/kg.

-Europe plasticizers spot prices at 13-month high, no sign of year-end slowdown

As sources embark on December talks for European plasticizers, spot prices have reached 13-month highs and there is no sign of the traditional year-end slowdown.

– Limited supply and good demand

– Consumers build stock

The supply/demand balanced has pushed prices higher and spot numbers reached levels last seen in October 2019. Petrochemical PETBottle Recycling H2

“It is not a price issue – it is an availability issue today,” one seller said.

In 2018, the global plastic recycling market reached a value of $41,238.8 million and is expected to generate a value of $64,139.7 million in 2024, advancing at an 8.6% CAGR during the forecast period (2019–2024). The market is growing due to the rising focus on reducing the plastic waste volume and government policies and initiatives for increasing the adoption of recycled products. On the basis of type, the market is classified into polyethylene (PE), polyvinyl chloride (PVC), polyethylene terephthalate (PET), polypropylene (PP), polystyrene (PS), and others.

In terms of source, the plastic recycling market is divided into sheets, wires & cables, packaging, pipes, molded products, and others (which include plastic waste generated from disposables, fabrics, and tarpaulins). The packaging division dominated the market during the historical period (2014–2018), holding a volume share of more than 78.0% in 2018. Petrochemical PETBottle Recycling H2

-A circular economy for plastics: the time is now

This year’s Society for Plastic Engineers‘ Plastics and the Circular Economy virtual conference saw Cleanaway CEO and Managing Director Vik Bansal outline his plan for creating the right environment to drive closed-loop plastic recycling in Australia.

“Set against the backdrop of the recent National Waste Policy Action Plan, defined timings for the Waste Export Ban and Container Deposit Schemes having opened or imminent in every Australian state, the time is now for companies to look at the waste value chain and take action,” Bansal said. Petrochemical PETBottle Recycling H2

Clean energy company Monolith Materials on Sunday said it has received an investment from Mitsubishi Heavy Industries (MHI) Americas to support its commercial-scale, emissions-free hydrogen manufacturing technology.

Monolith Materials is the first US manufacturer to produce turquoise hydrogen on a commercial scale, with the announcement the latest in a series of recent investments by MHI in support of achieving a decarbonised world.

“Successfully scaling Monolith’s technology to serve a global marketplace will benefit from the kind of investment that we have from MHI,” stated Rob Hanson, co-founder and CEO of Monolith Materials. Petrochemical PETBottle Recycling H2

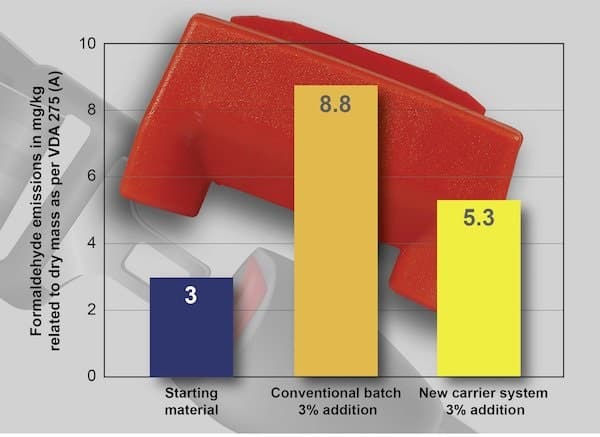

-Tosaf optimises carrier material for low-emission POM masterbatches

Tosaf Color Service’s colour, functional and combination masterbatches for POM are now based on particularly low-emission carrier materials.

In addition, the pigments have been optimally selected with regard to their effectiveness. As a result, the low emission data of the starting material – depending on the POM type – are almost fully retained, even after colouring and compounding. The new masterbatches thus help ensure compliance with the strict specifications of the automotive industry for moulded parts, and also with the requirements regarding personnel safety.

The emission-optimised masterbatches are suitable for all POM grades. At the customer’s request, ongoing applications can also be switched to the new technology.

Tests carried out at an independent institute show the efficiency of the adopted measures, based on the example of a conventional, low-emission POM grade, to which a combination masterbatch was added. Petrochemical PETBottle Recycling H2

-End-of-life automotive speakers to provide source of rare earths

Mkango Resources, a specialist in rare earth material extraction, has announced that HyProMag and partners European Metal Recycling (EMR) and the University of Birmingham have been awarded a grant from the Industrial Strategy Challenge Fund, delivered by UK Research and Innovation (UKRI), for a new project entitled Rare-Earth Extraction from Audio Products (REAP). Petrochemical PETBottle Recycling H2

REAP will investigate ways of recycling rare earth magnets from speakers used in automotive and consumer electronics applications, which account for approximately 20% of the current market for rare earth magnets.

Nick Mann, operations general manager of HyProMag, said, “With demand for rare earth magnets accelerating, it is imperative that we find viable economic solutions to reclaim end-of-life magnets that are currently lost. Current estimates suggest that the recycling rate of rare earth magnets from end-of-life products stands at below 5%.

Petrochemical PETBottle Recycling H2