Petrochemicals Biodegradable PET Flakes 16-09-2020 - Arhive

Petrochemicals Biodegradable PET Flakes

Crude Oil Prices Trend

-How Wittmann Battenfeld has increased its medtech focus

The COVID-19 pandemic put paid to such plans but many WIBA UK customers – such as White Horse Plastics and Linear Plastics – have since been turning their hand to medtech manufacture against the pandemic and WIBA UK has been in the vanguard of support.

Wittmann Battenfeld offers its MicroPower, EcoPower and SmartPower moulding machines (15-550t) in medical versions: All three are available in multi component format. Minimum emissions are standard and all machines can be upgraded for cleanroom purposes to the EN-ISO 14644 medical standard.

Micromoulding has led the way for many customers. When Wittmann acquired Battenfeld in April 2008, the revamping and renaming of the latter’s micromoulding machine was high on the list.

The MicroPower was the result and it has been particularly effective in leading the production of new polymer-based dental and medical implants and other small components.

-Lubrizol announce new materials for sports and recreation TPU innovation

Adapting to consumer trends in terms of sportswear can be difficult to keep up with, and Lubrizol believes it can bring unique, meaningful solutions to its customers with new materials optimised for training shoes. Petrochemicals Biodegradable PET Flakes

Addressing the biggest trends in sportswear production can be difficult to maintain. With a growing demand for sustainability, comfort, aesthetics and customisation, the needs and wants of consumers are continuously changing.

Julie Shlepr, Business Development Director for Engineered Polymers, said: “There’s a strong push to fast-track development to respond to consumer style preferences and to enable customisation. We see colour, texture, haptics, structure, cushioning, lightweight and novel fabrication methods as ways to enable this and allow close-to-consumer production.”

-Trinseo and Fernholz commercialise rPS for food packaging

Trinseo has announced that it has developed a new grade of post-consumer recycled polystyrene, together with the German packaging manufacturer Fernholz.

The latest Form Fill Seal (FFS) formulations incorporate 40 per cent rPS, depending on final application, due to Trinseo’s unique technology, which embeds the material into the polymerisation process using solvent processes.

Nicolas Joly, Vice President Plastics and Feedstocks at Trinseo, said: “With rPS technology, we have developed a process that will help the plastics industry conserve resources and reduce oil consumption. We are very pleased to work with Fernholz as our collaboration partner to jointly respond to consumer and market expectations, offering companies a tangible solution for more sustainable packaging.” Petrochemicals Biodegradable PET Flakes

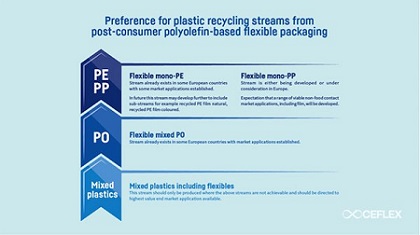

-CEFLEX recommends use of recyclable mono-materials for flexible packaging

As part of its ‘Issue Alignment’ process CEFLEX stakeholders are working with Swiss University ETH to collect and assess topics which are essential to realising a circular economy for flexible packaging. Petrochemicals Biodegradable PET Flakes

These issues are being tackled individually to create considered and aligned positions on each topic. The result has been its first Position Paper on ways to achieve this goal.

The first CEFLEX Position Paper, entitled ‘Accelerating the circular economy for flexible packaging – a recommendation for recyclable mono-materials’ is now being made available.

Taking into account the current best-practice technologies established in Europe, CEFLEX strongly recommends the use of flexible packaging made from recyclable mono-materials. The paper clearly states the need to evaluate functional requirements of packaging and, when possible, to redesign existing flexible packaging to a recyclable mono-material.

-RadiciGroup bets on research and innovation: sets up Radici InNova consortium

The new company’s R&D to focus on sustainable solutions by pooling the competencies of all RadiciGroup companies Petrochemicals Biodegradable PET Flakes

RadiciGroup has announced the founding of Radici InNova, a non-profit consortium, to carry out the Group’s strategic aims of ensuring business continuity, improving corporate competitiveness and creating value for the community. The new company’s main object is the development of new research and innovation projects for the chemical, high performance polymers and advanced textile solutions sectors, in accordance with the RadiciGroup sustainability strategy.

Indeed, Radici InNova renews and strengthens RadiciGroup’s commitment to a development model that balances economic profitability with environmental sustainability and social equity.

The new company will take advantage of and improve the synergies of the R&D activities that have long been carried on by the RadiciGroup Specialty Chemicals, High Performance Polymers and Advanced Textile Solutions Business Areas.

-Automotive – impact on chemicals

The automotive industry has an important relationship with the chemicals sector while remaining an instrumental force on the global economy as an employment-intensive sector.Petrochemicals Bioplastics PET Flakes

In a fast-changing world, automotive manufacturing is susceptible to unique challenges. While vehicle manufacturers are impacted by material prices, trends impacting the market ripple upstream. Petrochemicals Biodegradable PET Flakes

Globally the automotive sector continues to recover, led by a very strong performance in China. However, there are concerns about balance sheets with some producers struggling to survive in the short term.

Long-term investments for trends – including tightening emission standards, a growing push to electrify and shared-car ownership – have already left firms cash strapped. The pandemic, lockdowns, supply chain disruptions and associated sales cuts have further slashed profitability. This could lead to greater rationalisation or strategic partnerships.

-Chemical recycling of plastic waste

From plastic waste to new chemical products

Plastics do have proven benefits during their use phase – for example preservation of food loss in packaging applications, lightweight construction of vehicles, and building insulation. Plastic waste, however, and in particular plastic waste in the context of marine littering, is a major global challenge.Petrochemicals Bioplastics PET Flakes

There is also increasing regulatory pressure regarding recycling targets and recyclability on the one hand and strong commitments of our customers towards increasing the share of recycled material in their offerings on the other hand.

Solving these challenges requires innovation and joint efforts globally across the value chain. Petrochemicals Biodegradable PET Flakes

-Fashion Forward: Why Using Sustainable Materials Is More Important Than Ever

In the fashion industry, sustainability and innovation aren’t at odds with each other. More than ever, brands and designers are reducing their environmental impact by delivering beautiful, high-performance products that are made with sustainable and waste materials — and ECONYL® regenerated nylon is helping them do it.

Made from waste such as old carpet, fishing nets and textiles scraps, our regenerated nylon performs on the same level as virgin nylon, but with a significantly decreased environmental impact on our planet. Compared to material made from oil, ECONYL® regenerated nylon reduces the global warming impact of nylon by up to 90 percent. And for every 10,000 tons of ECONYL® raw material, we are able to avoid 65,100 tonnes of CO2 eq. emissions. Petrochemicals Biodegradable PET Flakes

This push for more sustainability across the supply chain has resulted in stunning products, with more than 1,000 brands using ECONYL® in their designs. It’s an important direction for the industry and a crucial departure from less sustainable practices and their negative impact on the environment. This movement is not only great for consumers, who are increasingly focused on the environment and sustainable actions, but also for the planet.

As the chairman and CEO of Aquafil SpA, I believe sustainability is a mindset and a must for those who wish to remain relevant in the marketplace and be true innovators making a difference. As we continue to usher in a new era of sustainability and foster change in the fashion industry, sustainable fibers like ECONYL® regenerated nylon have helped brands produce beautiful designs and express their creativity.

-Eurozone chemicals output up slightly in July, industrial recovery shows ‘signs of fatigue’

Chemicals output in the eurozone rose slightly more than 1% in July, month on month, a lower increase than average industrial production levels, the EU’s statistical office Eurostat said on Monday. Petrochemicals Biodegradable PET Flakes

In the wider 27-country EU, chemicals output also rose slightly more than 1%.

These modest increases compared with more than 4% increase in industrial production in both the EU and the eurozone.

However, the increase was not enough yet to compensate for falls in output during the second quarter amid lockdowns.

Analysts at Oxford Economics said the recovery was showing “early signs of fatigue” as rising coronavirus infections across Europe were denting confidence.

“Eurozone industrial output has recouped a large portion of its losses since the April trough but still remains almost 8% below the pre-pandemic levels,” said the analysts.

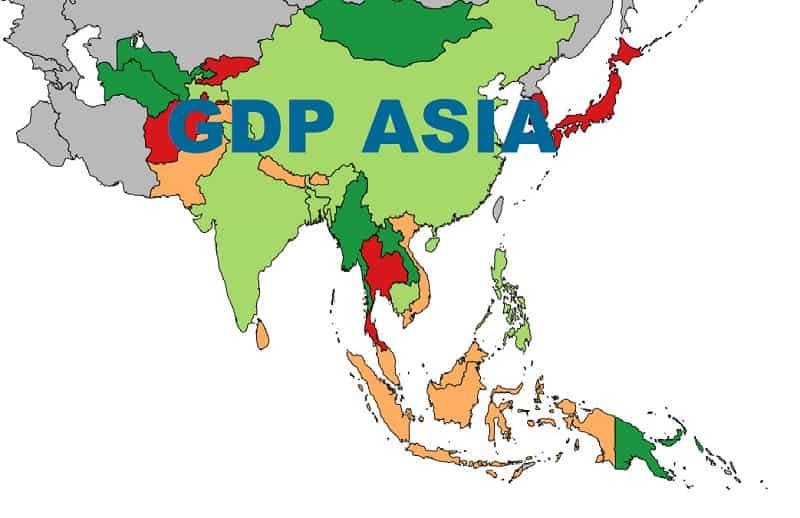

-Developing Asia GDP to contract in 2020, first recession in almost six decades – ADB

Economic prospects in developing Asia have worsened amid a revival of coronavirus cases in some areas, with regional GDP expected to contract by 0.7% this year, the Asian Development Bank (ADB) said on Tuesday. Petrochemicals Biodegradable PET Flakes

The contraction marks the first regional recession in nearly six decades, it said in a report. The ADB previously projected the region’s economy to grow by 0.1% this year.

ADB’s list of developing countries consists of 45 countries in the Asia-Pacific.

The region’s GDP is projected to grow by 6.8% in 2021, but this will still leave it substantially below expectations before the coronavirus pandemic, the ADB said.

“The threat of a prolonged pandemic is the main risk to the outlook. A return to more stringent containment measures could slow or even derail recovery and possibly trigger financial turmoil,” said Yasuyuki Sawada, ADB’s chief economist.

-Cat-HTR Chemical Recycling of Waste Plastic

Petrochemicals Biodegradable PET Flakes