Petrochemicals Nylon CarbonFiber News 17-07-2020 - Arhive

Petrochemicals Nylon CarbonFiber News

Crude Oil Prices Trend

-Albis now operating separate resin distribution, compounding units

Albis Plastic GmbH has completed its split into two separate business units.

The firm’s resin distribution business will continue to operate as Albis, while its compounding unit will do business as Mocom. Both units are part of Hamburg, Germany-based Otto Krahn Group. Plastics recycler Wipag and chemicals distributor Krahn Chemie also are part of the group.

Otto Krahn CEO Philip Krahn said in a July 14 news release that the new structure “is good for our customers, good for our distribution partners and good for us as a group.”

-Dedicated to changing petroleum-based plastic items into bio-plastic.

Let’s change the world.

Welcome to PLA Bottles EU

Petroleum-based, single-use plastics such as bottles, caps, straws, and food utensils, clog landfills and contaminate our landscapes and watersheds.

-NGO Recommendations on Chemical Recycling Legislation

Zero Waste Europe (ZWE) and the Rethink Plastic Alliance (RPa) published a policy briefing on 7 steps to effectively legislate on chemical recycling.

‘The concept of ‘chemical recycling’ has been promoted by the industry for decades, including as a solution to the current plastic crisis.

The industry has been claiming that chemical recycling technologies are able to treat plastic waste that is currently not recovered through mechanical recycling, thus enabling an entirely circular economy in plastic. Petrochemicals Nylon CarbonFiber News

They are promoted as ‘green alternatives’, but the truth is there is no truly viable end-of-life solution for them at the moment beyond incineration at Energy Recovery facilities.

Contrary to popular belief, bioplastic isn’t good for industrial food waste composting. Quite the opposite. Petrochemicals Nylon CarbonFiber News

Let’s have a closer look at what’s going on here.

The basic material for cornstarch (sugar derived from corn) takes a lot of land and water to grow and fuel to harvest and transport, and the crop is usually genetically modified as it is generally the same crop used to produce feed for livestock. The global rearing of livestock is, in itself, a major cause of climate change; feed is rarely thought about as a factor in this, and the use of GM crops to resist ‘pests’ raises concerns about the impact this has on the ecosystem (though the higher yields using less land is an environmental point in favour of GM, concerns remain about herbicide usage and the crops’ effect on pollinators, etc.).

-LANXESS’ New Recycled Glass Fiber-based Polyamide 6 Compounds for Automotive

LANXESS has recently developed Durethan ECOBKV30H2.0, ECOBKV35H2.0 and ECOBKV60XF as the most recent examples of products made in line with its strategy. Recycled fibers manufactured from waste glass make up 30%, 35% and 60% by weight respectively of these three new polyamides 6 compounds.

Ecocycle, an independent inspection company, has examined the amount of recycled material in each compound and the long-term use of the glass waste stream using the mass balance method and awarded an ecoloop certificate in accordance with ISO 14021:2016. The glass comes from waste left over from glass fiber production (post-industrial recycling). Petrochemicals Nylon CarbonFiber News

Focus on Automotive Applications

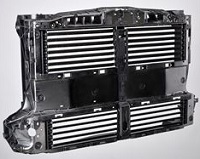

HPM’s primary target for the three new compounds is the automotive industry . Durethan ECOBKV60XF offers exceptional strength and rigidity, which makes it suitable for manufacturing structural components such as front ends, pedal bearing brackets and A-, B- and C-pillars, as well as lightweight battery trays for electric vehicles.

-Carbon fiber-reinforced polyamide performs in engine part

When École Polytechnique de Montréal (Montreal, Canada) developed a race car to enter in the 2010 Formula SAE competition, it turned to Solid Concepts Inc. (Valencia, Calif.) and additive fabrication for help. Petrochemicals Nylon CarbonFiber News

When École Polytechnique de Montréal (Montreal, Canada) developed a race car to enter in the 2010 Formula SAE (Society of Automotive Engineers, Warrendale, Pa.) competition, the school’s racing team turned to Solid Concepts Inc. (Valencia, Calif.) for help.

(Solid Concepts also is mentioned in this issue’s report on the recent SAMPE Tech Conference. See “Wichita welcomes SAMPE Tech,” under “Editor’s Picks,” at right.)

For their test engine, team members wanted to create a number of unique composite engine parts that, based on computational fluid mechanics (CFD) modeling, could achieve higher performance and withstand the engine environment at much reduced weight, compared to aluminum parts.

Their complex shapes and relatively small sizes, however, would make conventional tooling and molding both expensive and time-consuming.

But the parts were a natural fit for additive fabrication, the general process that undergirds rapid prototyping/manufacturing technologies in which a part is created directly from computer data, without tooling.

-Polyplastics Targets PBT Grades for ADAS Applications

Alkali resistance, hydrolysis resistance, and heat shock resistance are characteristics of PBT resin that make it suited for use in ADAS components.

As the automotive industry makes a strong shift to electric vehicles, global engineering plastics supplier Polyplastics sees strong potential for its innovative resin products in advanced driver-assistance system (ADAS) components that enable autonomous driving. The company’s Duranex polybutylene terephthalate (PBT) materials — targeted for actuators and communication devices — deliver strong durability, alkali resistance, hydrolysis resistance, and heat shock resistance.

In by-wire systems, the actuator requires a higher level of reliability as ADAS parts become more sophisticated and electronic controls become automated. Polyplastics’ Duranex PBT is chosen for many electric actuator parts because it continues to perform even in harsh environments. Petrochemicals Nylon CarbonFiber News

Lanxess says that a seat bolster for the Ford Kuga SUV features its Durethan BKV30H2.0EF glass fiber reinforced polyamide (PA) as part of plastic-metal composite component. Petrochemicals Nylon CarbonFiber News

According to Ulrich Dajek, hybrid design expert at Lanxess, the material is high flow and can be processed at lower injection pressures. ‘For this reason, smaller injection molding machines with lower clamping forces can be used in the production of the hybrid bolster,’ he said. ‘This has a positive effect on the machine running costs and allows greater flexibility in terms of machine selection and production planning.’

-US plastic, chemical demand remains soft, margins stay depressed

Demand for plastics and basic chemicals in the US was soft, while margins remained depressed, the Federal Reserve said on Wednesday.

The anecdote was among several that the US central bank collected in its recent Beige Book, a summary of US economic activity during the past six weeks among the Fed’s 12 districts. The latest Beige Book contains information collected through 6 July.

The comments about demand came from the 11th Federal Reserve District, which includes northern Louisiana and all of Texas, and has many of the nation’s refineries and petrochemical plants.Petrochemicals Nylon CarbonFiber News

Utilisation rates modestly rose for refiners, although their margins remain depressed, the Fed said.

Chemical companies said demand remains strong for personal protective equipment (PPE) and disinfectant products.

-Coca-Cola European Partners invests in creation of circular economy for PET in Western Europe

CCEP Ventures funding for CuRe Technology supports progress towards eliminating virgin oil-based PET from its packaging.

16th July 2020, London: Coca-Cola European Partners (CCEP), the world’s largest independent Coca-Cola bottler, has taken an important step on its journey towards 100% recycled PET (rPET) for its plastic bottles by funding CuRe Technology – a recycling start-up which seeks to provide a new lease of life for difficult to recycle plastic polyester waste.Petrochemicals Nylon CarbonFiber News

The funding from CCEP, through its innovation investment fund, CCEP Ventures, will enable CuRe to accelerate its ‘polyester rejuvenation’ technology from pilot plant to commercial readiness. Once the technology is commercialised, CCEP will receive the majority of the output from a CuRe-licensed, new-build plant.

Petrochemicals Nylon CarbonFiber News