Petrochemicals PETrecycled Polypropylene 25-09-2020 - Arhive

Petrochemicals PETrecycled Polypropylene

Crude Oil Prices Trend

-Total Corbion PLA announces the first world-scale PLA plant in Europe

Total Corbion

Total Corbion PLA, a 50/50 joint venture between Total and Corbion, announces its intention to build its second PLA plant with a capacity ramping up to 100,000 tons per annum. This expansion would make Total Corbion PLA the global market leader in PLA, firmly positioned to cater for the rapidly growing demand for Luminy® PLA resins. The new plant is planned to be located on a Total site in Grandpuits, France and to be operational in 2024.

“Announcing our second plant project, less than two years after we started up commercial scale production at our first plant in Thailand, demonstrates our commitment to develop PLA bioplastics and our ambition to become the world leader in PLA. We are proud to be the first company launching a commercial scale Lactic Acid to PLA plant in Europe” comments Stéphane Dion, CEO of Total Corbion PLA.

Corbion and Total, the two shareholders of the joint venture, are fully supporting its ambitious growth plans.

-Europe R-PET demand fluctuates, October outlook pessimistic

Senior Editor for Recycling, Matt Tudball, looks at what’s been happening in the European recycled polyethylene terephthalate (R-PET) market this week, including:

Fluctuations in demand levels

Potential post-consumer bottle tightness on horizon

Outlook for October price discussions

– Partnership paves the way for closed loop recycling to keep polystyrene out of landfills

INEOS Styrolution and AmSty, two of the largest global producers of polystyrene, announce plans to construct a joint 100 ton per day facility in Channahon, Illinois, that will utilize the Agilyx advanced recycling technology to recycle post-use polystyrene products back into virgin-equivalent styrene monomer.1

“The overarching goal of Cyclyx is to dramatically increase the recyclability of post-use plastics with a priority for fully circular pathways, as well as assisting in the development of new supply chains that will aggregate and preprocess larger volumes of post-use plastics than current systems.”

-Intertextile Shanghai Apparel to host Autumn Edition

Intertextile Shanghai Apparel Fabrics – Autumn Edition will be held from September 23-25, 2020, in Shanghai. It will welcome 3,400 exhibitors from 20 countries and regions. Along with pavilions and dedicated product zones, the inaugural Hybrid Showcase will allow exhibitors who cannot attend the fair, to showcase their products in a designated display area. Petrochemicals PETrecycled Polypropylene

Along with the international pavilions, the eight exhibition halls spanning over 200,000 square metres will also include a number of product zones and group pavilions. The comprehensive product zones includes Accessories Vision, Beyond Denim, Premium Wool Zone, Verve for Design, All About Sustainability and Functional Lab. A wide range of innovative exhibitors will feature in this year’s Group Pavilions which includes Button & Garment Accessories Industry Chamber (Hong Kong), DuPont Trading (China), Ecocert (China), Hyosung group (Korea), Lycra (USA), KTC (Korea), Lenzing Fibers (Hong Kong), and Oeko-Tex Pavilion (Switzerland).

-Borealis and MENSHEN launch new packaging closures made of post-consumer recycled resin

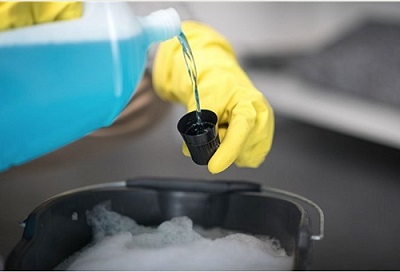

Borealis and MENSHEN, a leading specialist for plastic closures and packaging systems, have collaborated on a series of 10 packaging closures based on Borcycle.

Borcycle is an evolving recycling technology which transforms polyolefin-based waste streams into value-adding versatile solutions and can be used to manufacture a range of compounds made of recycled polyolefins (rPO) which are suitable for use in sophisticated rigid packaging applications. Petrochemicals PETrecycled Polypropylene

Borealis says this evolving technology unites its recycling and compounding expertise with its own Borstar® multi-modal and nucleation technologies. These packaging solutions are predominantly made for use in laundry and homecare and include 2K closures.

-Toyo Ink Europe Specialty Chemicals develops near-infrared sortable black masterbatch

Toyo Ink Europe Specialty Chemicals S.A.S. (TIESC), a member of the Toyo Ink Group, has developed a whole new range of Lioplax black plastic masterbatch for near-infrared (NIR) sorting and subsequent material recovery. Petrochemicals PETrecycled Polypropylene

Toyo Ink says the new packaging masterbatch supports the recyclability of black plastic waste that is currently destined for landfill, thus helping our customers in closing the loop on the circular economy.

-German economy to reach pre-pandemic levels by Q4 2021 on industrial pick-up

Germany’s economy is on track to recover pre-pandemic levels by the fourth quarter of 2021 as industrial activity is set to bounce back strongly, research institute Ifo said on Tuesday. Petrochemicals PETrecycled Polypropylene

Despite experiencing its deepest depression in its post-war history in the first half of 2020, Germany’s containment measures to cap infection rates enabled increased industrial activities, compared with other nations. Petrochemicals PETrecycled Polypropylene

The Ifo Business Climate index is almost at pre-crisis levels for many sectors, with significant improvements from the lows reached in April as shutdown restrictions have been relaxed.

GDP in 2020 is expected to fall by 5.2%, year on year, but growth of 5.1% in 2021 would place Germany’s economy at pre-pandemic levels by the fourth quarter.

The recovery would gain pace in 2022, with GDP expected to grow by 1.7%.

W-Cycle has developed plastic-free packaging made from upcycled sugarcane waste / Pic: GettyImages/undefined undefinedW-Cycle has developed plastic-free packaging made from upcycled sugarcane waste / Pic: GettyImages/undefined undefined

Made from upcycled sugarcane waste, the ‘fully compostable’ offering can be used for greasy, wet, or hot food. FoodNavigator speaks to W-Cycle co-founder Joseph Siani to find out more. Petrochemicals PETrecycled Polypropylene

Israeli foodtech start-up W-Cycle is concerned about plastic pollution, with an estimated 8m tonnes entering the marine environment every year.

At the same time, food waste is a growing concern. Upcycling food chain by-products, such as discarded seed husks and crop pulp, presents an opportunity for industry – and one that Israeli start-up W-Cycle is seizing with both hands.

-PepsiCo Partners to Prevent Ocean Plastics in Thailand

Burgess Davis, VP, Global Sustainable Plastics at PepsiCo, shares how The PepsiCo Foundation has joined TerraCycle to dramatically reduce the volume of marine debris and plastic waste found in the world’s waterways.

In 2018, TerraCycle founded the TerraCycle Global Foundation (TGF) with $450,000 in seed money from The PepsiCo Foundation. TGF is a 501(c)3 public charity dedicated to dramatically reducing the volume of marine debris and plastic waste found in the world’s waterways. The foundation’s inaugural platform is focused on Thailand (the Thai Foundation, or TGFT). Petrochemicals PETrecycled Polypropylene

In this interview, Burgess Davis, Vice President, Global Sustainable Plastics at PepsiCo, explains how the partnership is helping PepsiCo to reach some of its sustainability goals around packaging.

The manufacturing upgrades increase NatureWorks’ responsiveness to rapidly evolving market dynamics and high demand for Ingeo™ (PLA) biomaterials.

NatureWorks, the world’s leading manufacturer of low-carbon PLA biomaterials, today announced a slate of manufacturing technology projects, including lactide monomer purification efficiency, that will increase the availability of the full Ingeo™ (PLA) biomaterials portfolio by 10 percent. Petrochemicals PETrecycled Polypropylene

Installation is currently underway at NatureWorks’ facility in Blair, Nebraska, the world’s first and largest commercial-scale PLA manufacturing plant. The projects will be completed by the end of 2021.

-How sustainability will drive growth in the packaging industry

The recyclable properties of PET will drive growth in the packaging sector.

Brands are including more and more recycled content in their packaging to meet consumer demands.

The Global Plastic Action Partnership is bringing decision-makers together to forge collective solutions. Petrochemicals PETrecycled Polypropylene

Across the world people are learning that not all plastics packaging is the same. A unique type of recyclable plastic called Polyethylene Terephthalate – or PET – is commonly used for soft drink and water bottles. Today PET bottles are the most recycled plastic packaging in the world. This is set to increase as the world adopts a shared responsibility to end plastic waste. The coming decade will see collection of post-consumer beverage bottles reach close to 100%. Recycling is critical to our sustainable future as it delivers fewer greenhouse gases and less waste.

-Why the EU’s post-COVID recovery should go bio

The bioeconomy could play a significant role in Europe’s recovery from the COVID-19 crisis, if governments and industries capitalize on shifting demands and priorities, adapt to the new funding realities and learn some lessons regarding prevention rather than adaptation Petrochemicals PETrecycled Polypropylene

From businesses developing technological solutions to face the COVID-19 outbreak to companies producing biodegradable plastic products for hospitals and retail chains: many bio-based activities have proved to be crucial during the novel coronavirus pandemic and are coping better with the economic effects of lockdowns than others.

The European bioeconomy has an annual turnover of around 2 trillion euro and employs almost 18 million people. It represents industries and research organisations that use renewable biological resources from crops, forests, animals and microorganisms to produce food, materials and energy.

Petrochemicals PETrecycled Polypropylene

Petrochemicals PETrecycled Polyethylene 24-09-2020