Plastic Barrier CrudeOil Additive 16-11-2021 - Arhive

Plastic Barrier CrudeOil Additive

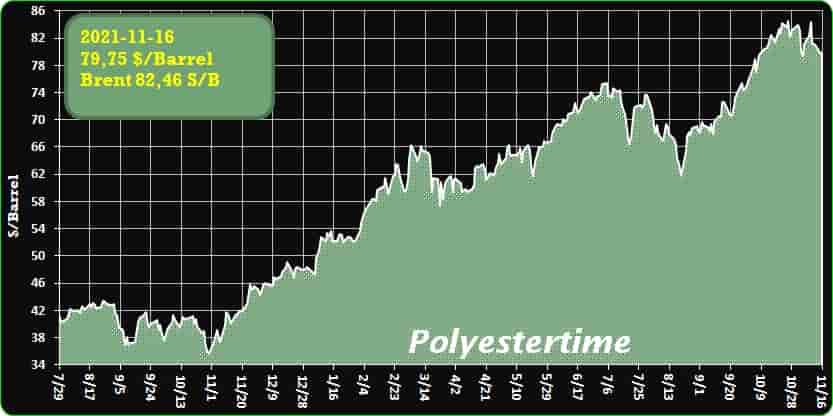

Crude Oil Prices Trend

-RadiciGroup filaments for additive manufacturing

At Formnext 2021, RadiciGroup launches product offering for 3D printing

On the one hand, the rapidly evolving market of additive manufacturing and, on the other, the RadiciGroup High Performance Polymers business area with its extensive experience in polymer compounding and recognized skill at optimizing materials to meet the requirements of various applications: those were the factors that brought about the development of Radilon® Adline, a range of 3D printing filaments based on special polyamide grades from the Group’s Radilon® family.

RadiciGroup has chosen the Formnext fair – taking place in Frankfurt from 16 to 19 November (Stand 12.1 B94) – as the launchpad for its new proposals aimed at the needs of 3D applications. Indeed, Formnext is the international meeting point for suppliers and users of industrial 3D printing.

Radilon® Adline products are characterized by their high performance and are suitable not only for prototyping, but also for the manufacture of functional parts. They have also been tested with different open 3D printing systems to ensure the ease of material processing.

“The technical requirements of additive manufacturing technology are special and not so simple to meet with semicrystalline polymers,” explained Chiara Devasini, marketing & development project leader of RadiciGroup High Performance Polymers. “That is why the entire first phase in the development of the 3D printing project was dedicated to identifying the polyamides meeting such requirements. Specifically, we opted to focus on materials for fused filament fabrication (FFF) and succeeded in developing high technical content products based on PA6/66 copolyamides with a fusion point of 195°C, which makes them suited to most 3D printers.”

-EIA predicts crude oil prices to go down in November and through 2022

The EIA forecasts that crude oil prices will begin declining in November 2021 and will decline through 2022, according to Hydrocarbonprocessing.

We expect that the price of WTI will fall from an average of USD76/b in January 2022 to USD62/b in December and that the price of Brent will fall from USD79/b in January 2022 to USD66/b in December, said EIA

Since the third quarter in 2020, global demand for crude oil and petroleum products has increased faster than production, which has led to inventory draws and increasing crude oil prices.

In February 2020, before the World Health Organization declared COVID-19 a pandemic, the spot price for Brent crude oil averaged USD56 per barrel and USD51/b for West Texas Intermediate (WTI). The spot prices for Brent fell to USD18/b and WTI to USD17/b in April 2020 because of the significant decline in demand caused by the pandemic.

Prices have since increased and are now above pre-pandemic levels because of returning demand and slow global oil production growth. In October, the price of Brent crude oil averaged USD84/b, and the price of WTI averaged USD81/b, the highest nominal prices since October 2014. In the EIA’s November Short-Term Energy Outlook (STEO), they forecast that global liquid fuels inventories will begin building in 2022, driven by rising production from OPEC+ and the United States, which will contribute to falling crude oil prices. Plastic Barrier CrudeOil Additive

The futures markets are similarly showing high prices in the near term compared with longer-dated contracts. Crude oil stock levels, among other factors, affect the relationship between near-term and longer-term futures prices.

Differences in prices between crude oil contracts for delivery in the near term compared with contracts for delivery at later dates indicate market expectations that stock draws will moderate. Low crude oil inventories, both globally and in the United States, have put upward price pressure on near-dated contracts, whereas longer-dated contract prices likely reflect expectations of a more balanced market. Because of the upward price pressure on the near-term contracts, near-dated contracts have higher prices than longer-dated contracts, a situation referred to as backwardation. When near dated contracts have lower prices than longer-dated contracts, it is known as contango.

As MRC informed before, US commercial crude stocks fell 3.48 million barrels to 413.96 million barrels in the week ended Sept. 17, to more than 8% below the five-year average, Energy Information Administration data showed. Stocks were last lower Oct. 5, 2018.

We remind that in late August, 2021, US crude stocks dropped sharply while petroleum products supplied by refiners hit an all-time record despite the rise in coronavirus cases nationwide, the Energy Information Administration said. Crude inventories fell by 7.2 million barrels in the week to Aug. 27 to 425.4 million barrels, compared with analysts’ expectations in a Reuters poll for a 3.1 million-barrel drop. Product supplied by refineries, a measure of demand, rose to 22.8 million barrels per day in the most recent week. That’s a one-week record, and signals strength in consumption for diesel, gasoline and other fuels by consumers and exporters.

-MEG prices keep low in anticipations of increasing supply

Thermal coal futures decreased sharp since late October and related commodities also posted significant declines. Spot MEG prices has dropped by around 30% from its previous high of 7,500yuan/mt to around 5,250yuan/mt. CFR China price dropped from $940/mt to around $710/mt. Plastic Barrier CrudeOil Additive

China domestic supply remained low in short term. Operating rate of all MEG units in China has decreased to around 57-58% this week with the unexpected shutdown of CSPC #2 unit.

However, overall supply is expected to increase with some units coming back and new startups. With the decrease in coal purchase prices, several producers were planning to restart their units. Operating rate of coal-based units was around 37% currently, and was expected to stand above 50% by mid-December. In terms of new units, Xinjiang Guanghui is testing its unit. Anhui Haoyuan plans to commission soon; Shenhua Yulin and Shanxi Meijin plans to test in end-November. In terms of integrated p In fundamentals, MEG market would be broadly balanced in November-December. Total MEG inventory is expected to increase apparently in January 2022. In short term, MEG prices are likely to keep low due to the weakness in commodity futures market and expectations of increasing supply. rojects, with the easing of power restrictions, Zhejiang Petroleum & Chemical is expected to test its Phase II-2 in end-November.

-Tighter supplies support China’s titanium concentrates

China’s import prices for titanium concentrates may return to an upwards trajectory in the coming weeks because of tighter spot supplies from international mining firms and firmer demand from the downstream dioxide sector.

Import prices for Vietnamese A grade 50pc minimum concentrate on 11 November were assessed stable from 4 November at $390-340/t fob China warehouse, with the range for Vietnamese B grade 54pc minimum concentrate firm at $370-380/t fob China warehouse.

Import prices for Australian 50pc grade concentrate on 11 November held unchanged from 4 November at $380-400/t cif China, with the range for Mozambique 50pc grade concentrate holding at $400-430/t cif China..Plastic Barrier CrudeOil TiO2

Prices rose slightly in late July because of limited output from international consumers and rising ocean freight costs, moving higher in September with renewed demand from the dioxide sector.

Most international mining companies have committed to long-term contracts in recent weeks. They have suspended offer prices in the past few days because of sparse spot availability.

Australian mining companies have temporarily halted price quotations to the Chinese market in the past few days because of tighter spot inventories. Offer prices from Vietnamese mining firms have been also limited in the past few days, as they just resumed production from the Covid-19 pandemic so are focusing on fulfilling contracts signed in mid-September.

Offer prices from Mozambique’s mining firms have held firm in recent weeks because of limited stocks. They have yet to start new contract negotiations with regular contracts.

Major international dioxide producers including Chemours, Tronox and Kronos have been operating at high capacity rates this year, in response to rising demand from the chemical sector following the global roll-out of Covid-19 vaccinations that have boosted economic growth. These dioxide producers are operating from titanium concentrate supplies produced by mines outside of China, which has tightened global spot feedstock availability.

China imported 350,900t of titanium ores and concentrates in September, up by 73.07pc from a year earlier. Imports during January-September rose by 30.72pc from a year earlier to 2.84mn, according to customs data. This was driven by higher demand, as large-scale domestic titanium dioxide producers have increased output during the same period prompted by a rise in dioxide prices.Plastic Barrier CrudeOil Additive

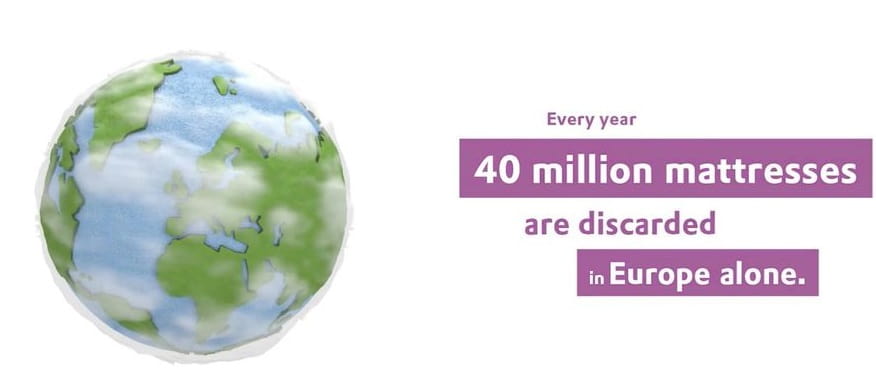

- The process helps the flexible polyurethane foam industry to increase circularity

- Hydrolysis technology enables used flexible polyurethane foams and mattress materials to be recycled

- Innovation will significantly reduce the number of mattresses incinerated or going into landfill each year

Essen. Evonik has used its expertise in polyurethane (PU) chemistry to develop an efficient chemical recycling process for converting flexible PU foams back to the original polyol raw material. Evonik’s new hydrolysis recycling process has the potential to achieve circularity in the flexible PU foam industry.

As the next phase of the development, Evonik will scale-up trials of its new process, which has been further strengthened by its partnership with The Vita Group, a leading provider of value-added and differentiated flexible PU foam products. The Vita Group has trialled the recycled polyols from Evonik’s hydrolysis process in several of its flexible foam applications.

According to the latest report from EUROPUR (European association of flexible polyurethane foam blocks manufacturers), some 40 million mattresses are discarded each year in Europe alone, with the majority ending up as landfill creating the equivalent of 600 kilotons of waste: including more than 300 kilotons of PU foam. With the potential to recycle the main component materials used in flexible PU foams and PU foam-based mattresses, Evonik’s process offers significantly higher use levels of the recycled polyol compared with existing commercialized technologies.

Evonik’s solution will contribute to the global flexible PU industry’s sustainability expectations of reducing waste and increasing the use of renewable raw materials in the production of its products. This enables Evonik to expand its position as a leading solutions provider for the PU industry and supports the entire Evonik Group’s objectives of establishing a fully functioning circular economy.

“It’s only by recycling products back to their raw materials and reusing them over and over again that we will enable a fully circular economy,” said Ralph Marquardt, Head of Evonik’s polyurethane additives business. “Our new hydrolysis process delivers recyclates of a quality and performance similar to that of virgin raw materials. Thus, innovative foam producers like our partner The Vita Group can meet their own sustainability targets, while continuing to deliver high-quality PU products.” Plastic Barrier CrudeOil Additive

“The Vita Group is renowned for our long-history of innovation in sustainability and investing in circular economy products. We recycle and rebond over 30,000 tons of trim each year, as part of our dynamic sustainability agenda,” said Ian W. Robb, Group CEO for The Vita Group. “Sustainability and innovation are central principles of every aspect of our business. We see it as our responsibility to be at the vanguard of the development of eco-friendly technology within our industry. This hugely exciting partnership represents a key milestone on our journey to achieving the circular economy we are all striving for, and we look forward to working closely together with Evonik.”

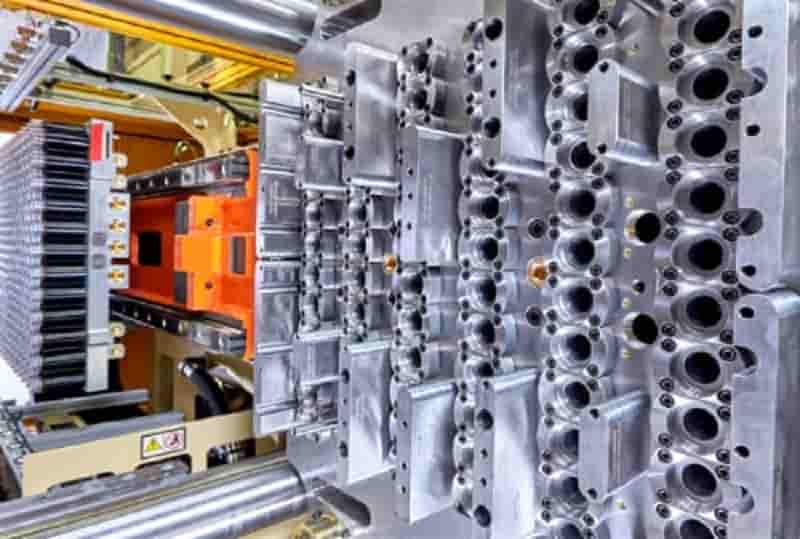

-Husky exonerated by the Italian antitrust

According to the Canadian manufacturer, the AGCM has ruled unequivocally against the existence of anti-competitive practices in the sale of PET presses and molds.

Husky PET mold Husky stated that the investigation launched in March last year by the Italian antitrust authority (AGCM) aimed at ascertaining the existence of an abuse of dominant position in the sale of injection molding machines has ended with an archiving. (HyPET HPP) and molds (Mold ID) for the production of PET preforms (read article).

The investigation started following a complaint filed in June 2017 by a competitor, whose name was not revealed. The closure of the investigation has not yet been communicated in the AGCM bulletin.

According to the Canadian manufacturer, after a long and in-depth investigation into company and technical documents, which lasted over two years, the Italian antitrust authority unequivocally ruled in favor of the company, having found no evidence on the alleged anti-competitive behavior contained in the anonymous report.

The complaint was based on the alleged abuse of a dominant position in an exclusionary manner in order to prevent other operators from competing in the production and marketing of injection molds for use in the machinery used for the production of PET preforms.

-Polymer Comply Europe: Risk of devastating ‘own goals’ in the plastics supply chain

2020 and 2021 have been difficult years for global manufacturing. Within that context, the plastics industry has been particularly severely affected. It is an industry which is subject to extreme volatility in normal times and depends on huge global shipments of a host of intermediate materials to maintain some semblance of balance between supply and demand.Plastic Barrier CrudeOil Additive

Polymer Comply Europe: Risk of devastating ‘own goals’ in the plastics supply chainPolymer Comply Europe

Polymer Comply Europe: Risk of devastating ‘own goals’ in the plastics supply chain

Since the beginning of the COVID-19 pandemic, it has been predictable that the industry would be a prime victim of inevitable shortages and disruption. What was rather less predictable was that 2021 would see in the supply base a higher level and longer-lasting Forces Majeures with a plethora of causes than even 2015.

In addition, extreme weather events of the type that perhaps we now need to learn to live with have combined with COVID to exacerbate the industry’s difficulties.

It has seemed to most European converters in recent months that a semblance of normality had returned. In fact, with few exceptions, most materials have become readily available and pricing has begun to reflect this reality. However, the conversion industry now seems to be confronted by energy ‘surcharges’ and other unilateral non-market price adaptation attempts which have the potential to pose an existential threat to large swathes of the industry.

-Revenue of China’s plastic manufacturers up 16.5 pct in Jan-Sept

China’s plastic industry logged steady growth in the first three quarters of the year, with the combined revenue of manufacturers surging 16.5 percent year on year, official data showed.

The total operating revenue of plastic product manufacturers topped 1.58 trillion yuan (about 246.6 billion U.S. dollars) in the January-September period, according to the Ministry of Industry and Information Technology.

These companies raked in total profits of 87.1 billion yuan, up 3.3 percent from a year earlier, said the ministry.Plastic Barrier CrudeOil Additive

In the first three quarters, the output of China’s plastic industry reached 58.81 million tonnes, up 9.3 percent year on year. Enditem

(ANSA-XINHUA).

-BarrierGuard® OxygenSmart™ Earns How2Recycle® Widely Recycled Designation

Ring Container Technologies, a leader in the plastic container manufacturing industry, today announced BarrierGuard® OxygenSmart™, a technology designed to protect both product freshness and the environment, has met the standards for the How2Recycle® “Widely Recycled” label.Plastic Barrier CrudeOil Additive

BarrierGuard® OxygenSmart™ is the first oxygen-additive barrier bottle technology that allows ketchup bottles to be designated as widely recycled, offering superior clarity and making it possible to meet consumer demands for more sustainable packaging. It’s 100% recyclable, patent-pending and proprietary technology uses less material without sacrificing protection and can incorporate more than 50% recycled content without compromising shelf life.

“OxygenSmart™ enables customers to achieve up to two years of shelf life with optimized technology that drives down overall costs,” said Tim Ferrel, Vice President of Business Development at Ring Container Technologies. “The customizable barrier allows them to further optimize profits by tailoring the barrier level to deliver an optimal shelf life.”

BarrierGuard® OxygenSmart’s™ How2Recycle® “Widely Recycled” label, with broad acceptance in curbside programs, reduces the need to create new material from fossil feedstock due to the circular benefits of readily recycled, highly reusable PET.

“Ring values sustainability and recyclability, and this technology can incorporate rPET without impacting the barrier performance,” said Paul Kelley, Vice President of Product Development at Ring Container Technologies. “Once again, Ring is disrupting the industry – this time with new technology that protects both product freshness and the environment.”

Plastic Barrier CrudeOil Additive