Plastic chemicals circular economy bioplastic 09-10-2018 - Arhive

-China – Polyethylene terephthalate is assessed mixed

PET Bottle grade export 1,240/1,280 $/ton – PET Bottle grade domestic market 9,850/9,950 yuan/ton – PET Filament grade domestic market 9,800/9,900 yuan/ton

PTA Taiwan 1,035/1,045 $/ton – PTA domestic market 7,800/7,900 yuan/ton – MEG $ 905/915 $/ton – MEG domestic market 7,450/7,550 yuan/ton – PX Korea 1,300/1,310 $/ton

POY 150D/48F domestic market 11,100/11,200 yuan/ton – DTY 150D/48F domestic market 12,600/12,700 yuan/ton – PSF domestic market 10,600/10,700 yuan/ton

Titan-Polymer signed a new contract for the supply of equipment for the production of BOPET films, the press service of the Titan Group of Companies reported.

The supplier of machines for cutting rolls of biaxially oriented polyethylene terephthalate (BOPET) films will be the German company Kampf Schneid-und Wickeltechnik GmbH.

-Crude Oil Prices Trend

-VietnamPlas: More US polyethylene to hit Vietnam’s shores in Q4 as US-China trade war intensifies

Ho Chi Minh City — More US polyethylene is expected to land in Vietnam during the fourth quarter, as the intensifying US-China trade war will see traders divert cargoes to avoid China’s retaliatory import tariffs on US PE, industry sources said on the sidelines of VietnamPlas 2018 in Ho Chi Minh City.

“Over the last two months, we’ve seen about 20,000 mt per month of US PE fixed, and will begin arriving from October onwards,” a trader from Mitsubishi Corporation Vietnam said Friday, adding that the exact figures will be seen only after Vietnam’s customs data is released.

-OMNOVA Acquires Leading Supplier in European Coating Resins

OMNOVA Solutions Inc. announced today that it has acquired Resiquímica, S.A., a Portugal-based producer of resins and binders for the coatings and building and construction industries. Resiquímica’s aqueous polymer emulsions and solvent-borne alkyd and acrylic resins are key elements used in a wide variety of residential and industrial coatings. Additionally, unsaturated polyester resins from Resiquímica are targeted at demanding applications in marine, food storage tanks, and more. Geographic markets served by Resiquímica include Portugal, Spain, France, and North Africa.

“This is another important milestone in OMNOVA’s path to becoming a premier global specialty solutions company. The acquisition of Resiquímica expands our technology and product offerings in the coatings and construction industries, strengthens our position in the EMEA region and enhances production flexibility and capabilities for our specialty business,” said Anne P. Noonan, President and CEO of OMNOVA Solutions. “We welcome the Resiquímica team to the OMNOVA family. The combined businesses are synergistic and will help accelerate growth.”

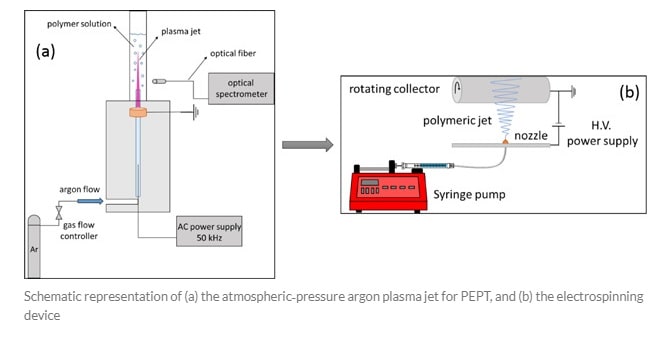

-Plasma To Enhance Nano and Microfibers through Electrospinning

In recent years, the chemical processes induced in liquids by non‐thermal atmospheric pressure plasmas have been extensively investigated due to the high potential of plasma in a wide variety of applications including synthetic chemistry. A very novel application of this promising research field is the use of non‐thermal plasma technology for the treatment of pre‐electrospinning polymer solutions. Electrospinning is well known as a cost‐effective and versatile technique for the fabrication of polymer‐based nano/micro fibers. Such synthetic and natural polymeric nanofibrous mats are of great interest for biomedicine, biotechnology, and industry: the nanofibers can be used for biological and/or chemical sensors, wound healing, drug delivery, and tissue engineering.

–Saudi crude shows record low carbon intensity

Among the countries producing more than 0.1 per cent of global oil production, Saudi Arabia ranks the lowest in carbon intensity (CI) of any major producer to extract, process, and transport its crude oil to the refinery gate, a study said.

In one of the most comprehensive oil field CI) studies ever published, a global team led by Stanford University has calculated the CI of the world’s active oil fields — with significant results for Saudi Arabia.

-Kaufland Romania Implements Reduced-Plastic Strategy

Kaufland has implemented a reduced-plastic strategy at a store in Bucharest, as part of the group’s willingness to tackle plastic waste.

The project, implemented in the Barbu Văcărescu store in the Romanian capital, sees more than 90% of disposable plastic materials removed and replaced with 100% biodegradable or compostable, environmentally friendly materials.

-BPA safety confirmed, once again, by final report from National Toxicology Program

BPAIf I told you that the final report on bisphenol A (BPA) has been issued, would you believe me? After nearly two decades of studies from various groups attempting to prove that BPA either causes—or does not cause—problems in humans, the results released last week once again confirm that BPA is safe in the minute levels found in plastic consumer products.

The results of the landmark CLARITY Core Study from the U.S. National Toxicology Program (NTP) is the final part of a multi-year, in-depth research program strongly supporting “recent statements from the U.S. Food and Drug Administration (FDA) that BPA is safe at the very low levels to which people are typically exposed,” commented Steven G. Hentges, PhD, Polycarbonate/BPA Global Group of the American Chemistry Council (ACC; Washington, DC).

-ASA/PC specialty compounds make their mark in weatherable automotive applications

The constantly growing demands in the automotive market with regard to design, economic and increasingly more important ecological aspects are challenging compounders to continuously optimize specific properties and develop new materials. Application-ready and affordable polymer blends play a significant role here.

ASA/PC compounds can be used in vehicle exteriors without the need for painting.

One requirement of automobile manufacturers, for example, is to create particular effects on a part after injection molding without complex and expensive subsequent operations. This is possible with polymer blends that satisfy a multitude of requirements due to their wide range of properties.

-EPCA ’18: Pessimism descends upon Europe petchems as challenges mount – EPCA president

European petrochemicals face several challenges amid an increasingly uncertain geopolitical outlook but the real, long-term test for the industry will be sustainability and how to become participants of a true circular economy, the president of the European Petrochemical Association (EPCA) said on Monday.

Marc Schuller, who is also a board member at French chemical major Arkema, added that the paramount feeling among petrochemical players in Europe is how a number of problems which could greatly impact the industry remain unresolved.

-EPCA ’18: Economic uncertainty, upward pressure on oil colour Europe petchems outlook

Nervousness about Europe’s manufacturing economy and the rising crude oil price colour the petrochemicals outlook at the start of the fourth quarter.

Petrochemical prices have struggled to keep pace with rising oil-based feedstock costs and margins are under pressure.

Economic sentiment has ratcheted down on the US-China trade war and the collapse of the Turkish lira.

And, while the eurozone appears to be performing relatively strongly, there are concerns about the outlook in Germany which relies so heavily on its export-driven manufacturing sector.

-Frost & Sullivan gives award for best innovation in the cosmetics sector to Bio-on

Minerv Bio Cosmetics, the 100% natural bioplastic microspheres biodegradable in soil and water, are named the year’s most innovative biobased product in the cosmetics sector.

Frost & Sullivan finds that “Bio-On is properly positioned to serve as a leader in the bio-polymeric ingredient revolution for the cosmetics industry”.

For Frost & Sullivan, the bioplastic microspheres patented by Bio-on are “incredibly versatile” and are “a sustainable alternative to synthetic polymers for use in not only cosmetics, but also in the food, healthcare, packaging, and FMCG industries. Looking ahead, the PHAs could provide a potential solution for cancer treatment within the next few years”.

-EPCA 2018: Asia Pacific Fibres considers restarting Indonesia PTA plant

Asia Pacific Fibres is considering restarting its purified terephthalic acid production plant in Indonesia, which has laid dormant since late 2015, a source close to the company said Monday on the sidelines of the 52nd annual EPCA conference in Vienna.

Since late 2015, Asia Pacific Fibres’ integrated PTA production plant has been closed and the company has been purchasing PTA in the open market to service its downstream polyester fiber production.

-Producers’ responsibility and plastic pollution crisis

The threat of plastic wastes is becoming alarming in Nigeria

Although, the federal and state authorities, even manufacturing firms are increasingly aware of the scale of plastic pollution, actions to curb the menace are taking a snail pace, write Chinedum Uwaegbulam, Bertram Nwannekanma and Victor Gbonegun.

With the production outpacing almost every other material population, plastic waste is now one of the biggest environmental scourges of the time. The scale of the challenge is daunting.

According to the State of Plastics report, only nine per cent of the nine billion tonnes of plastic in the world ever produced has been recycled. Most ends up in landfills, dumps or in the environment.

-Nasa Tests New Antibacterial 3d Printing Filament

NASA is testing the suitability of an antibacterial 3D printer filament for use in future space missions. The filament is made by Copper3D, a Chilean company with a base in the USA. The study, conducted in association with the University of Nebraska at Omaha, aims to overcome the health challenges faced by NASA astronauts in space.

3D printed antibacterial prostheses

A new research paper ‘3D printed antibacterial prostheses’ published in Applied Sciences journal investigates, “the development of 3D printed prostheses using antibacterial filaments” and the resulting “antibacterial properties of the 3D printed prostheses.” It is hoped that the research will lead to applications including postoperative prostheses, wound dressings, and surgical equipment.

-Sorting the Plastic Recycling Problem

As Smurfit Kappa’s Arco Berkenbosch has observed, a key to the success of paper recycling is the fact that everything from corrugated board to newspapers can go into the same stream. Simplicity for the consumer is crucial to a high collection rate. Given the multiplicity of polymers used in packaging, raising recycling rates based on a single collection stream depends on solving the challenge of efficiently identifying and sorting different plastics. Having explored a number of approaches to this challenge, a number of value chain stakeholders are now investing in research around two technologies that could make an important contribution: tracers and digital watermarking. Tim Sykes reports.