Polymers Petrochemicals Polyethylene furanoate 19-03-2019 - Arhive

- China – Polyethylene Terephthalate

PET and its chain continue to be weak.

- Polyamide6 and its chain continue to be steady.

PET Bottle grade export 1,050/1,090 $/ton – PET Bottle grade domestic market 8,250/8400 yuan/ton – PET Filament grade SD domestic market 7,700/7,850 yuan/ton – PET Filament grade BR domestic market 7,800/7,900 yuan/ton

PTA Taiwan 845/855 $/ton – PTA domestic market 6,400/6,500 yuan/ton – MEG $ 635/645 $/ton – MEG domestic market 5,050/5,150 yuan/ton – PX Korea 1,050/1,070 $/ton

POY 150D/48F domestic market 8,900/9,000 yuan/ton – DTY 150D/48F domestic market 10,500/10,600 yuan/ton – PSF domestic market 8,800/8,900 yuan/ton

Crude Oil Prices Trend

Asia naphtha’s crack spread rose to its highest in over two months as steady demand provided market support, shrugging off supply that is expected to remain ample in the days ahead.

Spot naphtha market fundamentals were perceived as soft going into the second quarter, as downstream cracker turnarounds is expected to rein in demand.

Naphtha’s crack spread to ICE Brent crude oil futures, closed at $57.33/tonne on 15 March, up from $48.40/tonne in the preceding week, ICIS data showed.

The crack spread, a measure of naphtha refining margins, stood at a previous high of $66.90/tonne on 2 January.

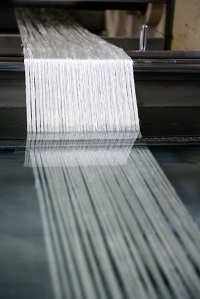

PrimaLoft fibres production. © PrimaLoftPrimaLoft, a leading expert in advanced material technology, has announced that its PrimaLoft Bio fibres are renewable in a circular economy. As a result of third-party testing, the polyester fibres have proven capable of being chemically recycled. This process breaks down polyester to its basic components so that it can be rejuvenated into a new high-performance material, without compromising its original integrity.

“The intention of PrimaLoft Bio was always to address the eventual end of life of a garment in an impactful way, while finding a solution for the industry-wide microplastics issue,” said Mike Joyce, PrimaLoft President and CEO.

March was certainly an eventful month for Knitting Industry with reports coming in from a number of leading industry events.

ISPO

Jana Bukolovska kicked things off with her report from ISPO, the world’s largest trade fair for sporting goods. The show welcomed around 80,000 industry visitors from 120 countries in February and a total of 2,943 exhibitors showcased their products and innovations, an increase of 5% over the previous year. The share of international exhibitors also set a record at 89%, with the largest participant groups by country being Germany, China, France, Great Britain, Italy, Taiwan and the US.

This year, the show occupied 18 halls of the Messe München exhibition centre and focused specifically on creating a consumer-centric environment that encourages valuable connections and helps accelerate the global evolution of sports. You can read Jana’s full report here – ISPO roadmaps future for industry.

The newly founded AFPA (Australian Fresh Produce Alliance) is currently in the news for its strategy of planning to get rid of plastics from the fresh produce aisles in Australia. The consortium, which is constituted by leading Australian fresh fruit & vegetable companies, is reportedly intending to make produce packaging completely recyclable and sustainable.

As per genuine sources, the AFPA is presently working on its mission, with necessary support from the country’s major retailers including Woolworths and Coles. Harry Debney, the AFPA Chairman, who is also the Chief Executive Officer of the largest Australian vertically-integrated fruit & vegetable company Costa Group, recently claimed that about 75% of the AFPA’s members are already into the use of recycled packaging.

Initiatives taken by sustainable packaging manufacturers to use environmental friendly packaging materials and technology in packaging products, has been supported by various organizations as well as governments. Sustainable packaging manufacturers are looking towards developing biodegradable plastics that will reduce carbon footprint. With a growing demand for a sustainability driven world, packaging experts and consumer products companies are focusing on “green packaging”.

Rampant Plastic Packaging Waste Prompts at Emergency of Adopting Sustainable Packaging Solutions

“More than 200 million tons waste created by plastics cause major landfill issues”. This is majorly reduced by the use of sustainable packaging.

Scientific studies have shown that light of any kind – whether in the supermarket, refrigerator, kitchen, or through a window – can cause food, beverages, and cosmetic products to degrade faster – often before they meet the expiration date.

With milk and other dairy products, for example, exposure to such light affects its taste, freshness, and nutritional value. Milk contains components that are sensitive to light, including riboflavin, also known as vitamin B2.

Noluma International, LLC uses technology developed to assess, measure, and certify light protection in packaging. Its unique, patented technology measures the light protection capacity of packaging as a function of its effects on the product contents.

The sale of LANXESS’ remaining 50% stake ahead of market expectations was prompted by a buy-out offer by joint venture partner Saudi Aramco based on the growth plans of the oil and gas giant for the business , according to CEO Matthias Zachert.

The Germany-based chemicals producer rolled its synthetic rubber assets into a joint venture with Aramco in 2016, giving the Saudi oil and gas giant the opportunity to diversify downstream, reducing LANXESS’ exposure to the automotive sector, and providing cash to diversify its portfolio.

Since then, the company has aggressively shifted its focus towards specialty chemicals, with a target of taking up leading positions in niche mid-sized sectors.

Magdi Batato, executive vice president, head of operations at Nestlé

Nestlé and resource management company Veolia are to develop recycling schemes as part of a collaboration aimed at reducing plastics leakage into the environment. The partnership will focus on waste collection, sorting and recycling of plastics material, with a particular emphasis on flexible plastics packaging.

Nestlé and Veolia will target 11 priority countries across Asia, Africa, Latin America and Europe and the partnership will explore technologies to establish viable models of recycling in different countries.

Malaysia expects no increase in plastics exports this year “due to challenging environmental issues”, but the overall industry should be able to pull a 2% growth amid a global economic slowdown, an industry executive said on Monday.

“With an anticipation of the slowing global and Malaysian economies, the plastics industry is expected to grow at about 2% in 2019,” Malaysia Plastic Manufacturers Association (MPMA) vice president CC Cheah told ICIS in an e-mail interview.

The country’s plastics shipments in 2018 were flat at Malaysian ringgit (M$) 14.6bn, weighed down by a contraction in exports of plastic bags following restrictions in the EU on the use of single-use plastics to reduce marine litter.

![]()

Plastics recycler and strapping maker Polychem Corp. is being sold.

The Mentor, Ohio-based company, which makes both PET and polypropylene strapping, was acquired by The Sterling Group, a private equity firm based in Houston.

Polychem, located in the eastern suburbs of Cleveland, has been family owned since the 1980s. The business includes a PET recycling facility that reprocesses post-consumer material for use in extrusion lines for strapping. The recycled PET also is sold to consumer packaged goods companies for their use.

Polychem also makes packaging equipment for its strapping customers, the new owner said in a statement.

Speakers detailed efforts to increase domestic reprocessing capacity for plastic scrap and to generate demand for PCR.

With China no longer welcoming imports of plastic scrap, investments are being made in the U.S. to add reprocessing capacity and to increase demand for postconsumer resin (PCR). The session Developments in Domestic Markets during the Plastics Recycling Conference and Trade Show, March 11-13 outside of Washington, detailed some of the progress that has been made in these areas and what remains to be done.

The state of North Carolina is growing its network of recyclers by investing in market development using economic development, tax incentives and grant funding, Sandy Skolochenko, industrial development specialist at the Recycling Business Assistance Center at the North Carolina Department of Environmental Quality, explained. The center works with local governments, waste generators and recycling businesses.