Recycled-polymers – Plastic-Circularity 19-05-2022 - Arhive

Recycled-polymers – Plastic-Circularity

-Chemours Leads Remove2Reclaim Project to Advance Plastic Circularity

The Chemours Company (“Chemours”), a global chemistry company with leading market positions in Titanium Technologies, Thermal & Specialized Solutions, and Advanced Performance Materials, announced its participation leading a three-year recycling research project in collaboration with industry, academic, and government experts to develop an efficient, cost-effective, and more sustainable process for recovering titanium dioxide (TiO 2 ) and polymers from plastic end-use products. The initiative, dubbed Remove2Reclaim, has the potential to drive significant environmental benefits, eliminating waste and reducing the amount of energy used in manufacturing, by enabling circularity across a much wider range of applications.

Current commercial scale recycling technologies do not allow polymers and additives to be effectively removed and separated, limiting the potential applications and overall quality of products made with recycled plastic. Remove2Reclaim is designed to change that. The project goal is to develop commercial-scale detection and extraction technologies that enable the removal and recovery of TiO 2 and polymers for reuse. Recycled-polymers – Plastic-Circularity

“Through the Remove2Reclaim initiative, we hope to help crack the code on effective plastic recycling, achieving a new level of circularity for the industry,” said Steven De Backer, EMEA Technical Marketing Manager at Chemours. “This initiative has the potential to reclaim thousands of tons of TiO 2 from different end-of-life streams, reducing raw material demands, and creating a new TiO 2 supply stream for our customers. We’re honored to lead this project in collaboration with a team of experts from across the value chain to pursue a common goal that benefits our shared planet.”

In the project’s first year, research partners have developed a sorting mechanism to effectively identify plastic wastes that contain TiO 2 and determined innovative solvent-based extraction routes to remove TiO 2 from different polymer matrices. Other project milestones include developing methods and equipment to detect TiO 2 in specific polymer matrices, recovering TiO 2 from the polymer by dissolution route, and eventually reusing the TiO 2 and polymer in new products.

Even though 59% of Americans have access to curbside recycling, only 27% of plastic bottles are currently recycled – a grim statistic that is not only bad for the environment but also bad for CPG businesses, like The Coca-Cola Co., that are striving to incorporate more recycled material in their packaging.

With an ambitious goal to use at least 50% recycled material in its packaging by 2030, The Coca-Cola Co. is confronting the limited availability of food-grade recycled plastics, which the Independent Commodity Intelligence Services’ Mechanical Recycling Supply Tracker estimated late last year at about only 10% of the global annual capacity of recycled polymers of more than 45 million metric tons. Of this, the vast majority (82%) was recycled polyethlene terephthalate which is used, among other ways, to create clear bottles, 12% was recycled polyethylene and 6% recycled polypropylene. Recycled-polymers – Plastic-Circularity

Competing for tight supplies with other major CPG food and beverage companies that have made similar high-profile commitments to use more recycled plastics in their packaging, The Coca-Cola Company is pacing its roll out of packages made from recycled resins while simultaneously working to increase limited supplies.

“We have a few really laser focused goals on driving the circular economy, including a goal to put up to 50% recycled material in our packaging and a goal to collect a bottle or can for every one that we sell,” creating a virtuous circle of demand and supply for food-grade recycled plastics, said Christine Yeager, director, sustainability at The Coca-Cola Co. North America, told FoodNavigator-USA.

In pursuing these goals, which are included in The Coca-Cola Co.’s World Without Waste initiative, she explained, the company has launched several packages in the US made from 100% recycled PET, including as of last year 13.2 ounce bottles of Coke, Diet Coke, Coke Zero Sugar, and Coca-Cola flavors in California, Florida and select states in the Northeast. Also in the New York and California markets it has launched 20-ounce bottles for select brands, including Coke, Diet Coke and Dasani, with another brand launching nationwide this summer.

“So, we’re continuing to build more and more recycled material into our portfolio, but some of the challenges are the availability of food grade quality material,” which requires more material to be collected and recycled, Yeager said.

-Sabic Launches Upcycled PBT Made with Ocean-Bound Plastic Waste

Automotive seating, fan housings, and electrical connectors and enclosures are among the applications.

Sabic has debuted a polybutylene terephthalate (PBT) engineering plastic that uses ocean-bound polyethylene terephthalate (PET) bottles as a feed stream for chemical upcycling into resin. Ocean-bound plastic is mismanaged waste that originates within 30 miles (50 km) off the coast and is likely to end up in the ocean.

The new grade — LNP Elcrin WF0061BiQ — is the latest addition to Sabic’s portfolio of chemically upcycled LNP Elcrin iQ materials, which help support circularity while serving as potential drop-in replacements for virgin PBT resins. LNP Elcrin WF0061BiQ resin is a candidate for consumer electronics applications such as fan housings in computers and automotive seating, as well as electrical connectors and enclosures. Recycled-polymers – Plastic-Circularity

Materials portfolio helps customers achieve sustainability goals

“We’re continually expanding our LNP Elcrin iQ portfolio – and the PET waste streams used to produce these materials – to help divert more plastic from the oceans while helping our customers incorporate recycled materials in their products, achieve their carbon neutrality goals, and meet consumer demand for greater sustainability,” said Sanjay Mishra, GM Technology & Footprint, Specialties, Sabic. “Within the next decade, we anticipate upcycling 10 billion plastic bottles into higher-performing, durable materials that deliver enhanced value to customers. Sabic is committed to working with the plastics supply chain to find new solutions to address urgent environmental issues, such as reducing ocean-bound plastic waste and achieving net zero carbon emissions.”

The new LNP Elcrin WF0061BiQ grade, a glass-fiber-reinforced PBT material, features non-brominated, non-chlorinated flame retardancy meeting the UL94 V0 standard at 0.8 mm and F1 rating. It also delivers heat resistance, toughness, and stiffness, and high flow well-suited for molding thin-wall applications for outdoor environments such as electrical equipment enclosures.

Drop-in replacement for virgin PBT

All LNP Elcrin iQ materials can serve as possible drop-in replacements for conventional PBT to help manufacturers increase the sustainability of end products. Sabic’s proprietary upcycling technology, which involves the repolymerization of ocean-bound PET into PBT, delivers virgin-like performance properties.

This process surpasses mechanical recycling in quality and consistency, according to the company. Recycled-polymers – Plastic-Circularity

“According to an internal life cycle analysis conducted in accordance with ISO 14040/14044 protocols, LNP Elcrin WF0061BiQ compound can offer potential reductions of up to 14% in the carbon footprint and up to 25% in cumulative energy demand, when compared to the virgin PBT compound reinforced with glass fiber,” said Darpan Parikh, Americas Customer Fulfillment Leader, Specialties, Sabic. “By replacing virgin material with our resins, customers can help reduce environmental impacts by reusing plastic waste and eliminating halogenated additives.”

-Coca-Cola will attach caps to bottles to boost recycling

Coca-Cola Great Britain has announced it is introducing attached caps to its plastic bottles to make the recycling of them easier.

The company said that production of bottles with attached caps will begin today (17 May) at its site in East Kilbride, Scotland. This will be followed by its facility in Edmonton, North London, and the rest of its of its UK sites over the next 18 months.

The move is set to cover the entire portfolio of brands including Diet Coke, Fanta, Sprite and others. It is planned to begin in Scotland this month and roll out across Great Britain, with new caps attached to 1.5l bottles of Fanta, Coca-Cola Zero Sugar and Diet Coke. Recycled-polymers – Plastic-Circularity

The switch is set to be completed for all plastic bottles across Coca-Cola GB’s range of brands by early 2024.

Recycling

Last year the company announced that it had reached its target of using 100% recycled plastic – excluding caps and labels – in all its 500ml or smaller bottles sold in Great Britain ahead of the plastics packaging tax taking effect.

The company joined a string of others in doing so, which has played a part in demand and prices for recycled plastic soaring in recent months.

Stephen Moorhouse, general manager at Coca-Cola Europacific Partners, Great Britain said: “This is a small change that we hope will have a big impact, ensuring that when consumers recycle our bottles, no cap gets left behind.”

Coca-Cola explained that bottle caps are often discarded and littered. The new design means that the cap stays connected to the bottle after opening, so the whole plastic bottle and attached cap can be recycled together reducing the potential for it to be littered.

This move was welcomed by Jo Churchill, resources and waste minister, who commented: “More businesses are finding innovative ways to tackle harmful plastic pollution and Coca-Cola’s new design will make it easier for people to recycle and help reduce litter.”

-Perstorp to be acquired by Malaysian market player

Specialty chemicals company Perstorp Group is to be acquired by Petronas Chemicals Group Berhad (PCG), a Malaysian company which has edged further into the polymers market in recent years via acquisitions, as well as its own resin portfolio.

PCG announced today that it has signed a Securities Purchase Agreement on 14 May 2022 to acquire the entire equity interest in Perstorp Holding AB. The agreement was signed with Financière Forêt S.à.r.l, a company under PAI Partners, a European private equity firm. Recycled-polymers – Plastic-Circularity

Jan Secher, President and CEO of Perstorp said, “We are excited to become part of the Petronas family. I see a strong commonality in values and priorities for how to take our respective businesses forward, meeting the challenges and opportunities of the future. By tapping into PCG’s strength and market leading position in the Asia Pacific region, we are confident that Perstorp can continue to develop into its next phase of growth. Being part of PCG means Perstorp gets the scale to increase the pace of innovation and accelerate our sustainable transformation, which is at the forefront of the chemical industry. PCG’s and Perstorp’s businesses complement each other very well.”

“Perstorp is an outstanding strategic fit for PCG and enables us to participate in attractive end-markets such as paints and coatings, construction, plastic additives, personal care and food, feed & nutrition, paints and coatings that share a robust growth outlook. This acquisition will also provide us critical talent, know-how, technological platforms and proven customer channels to address the pressing needs of the market for more eco-friendly and sustainable solutions,” said PCG Managing Director and CEO, Ir. Mohd Yusri Mohamed Yusof.

Perstorp is a niche provider of resins and coatings, as well as products for numerous other markets. The company has seven manufacturing sites in Europe, US and China (the 8th plant will be ready in India in 2023) and three research and development (R&D) centres worldwide.

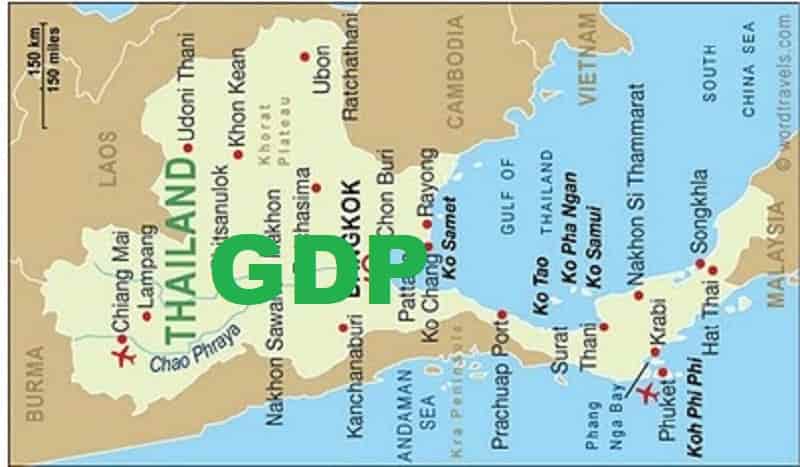

-Thailand Q1 GDP growth accelerates to 2.2% as COVID-19 restrictions ease

Thailand’s economy posted a first-quarter annualized growth of 2.2%, faster than the 1.8% pace set in the previous quarter, on the back of stronger private consumption and exports as COVID-19 restrictions have eased.

On a seasonally adjusted quarter-on-quarter basis, the economy expanded by 1.1% in the period January to March 2022, data from the Office of National Economic and Social Development Council (NESDC) show on Tuesday.

On a year-on-year basis, private consumption in the first quarter accelerated to 3.9% from 0.4% in the previous quarter.

Exports during the period grew 14.6% to $73.3bn, with chemicals and petrochemical products posting an 18.7% increase year on year.

Manufacturing posted a slower growth of 1.9% in the first quarter from 3.8% in the previous quarter. Recycled-polymers – Plastic-Circularity

Tourism receipts grew for the first time in 11 quarters, rising 63.8% year on year to $4.2bn in January-March 2022 as COVID-19 measures were relaxed. The sector is a major component of the Thai economy.

For the whole of 2022, the Thai economy is projected to grow by 2.5-3.5%, supported by improvement in domestic demand, recovery of domestic tourism, and continued export growth, NESDC stated.

Recycled-polymers – Plastic-Circularity