Recycling-Loop – PA66-low-carbon-hydrogen 08-07-2022 - Arhive

Recycling-Loop – PA66-low-carbon-hydrogen

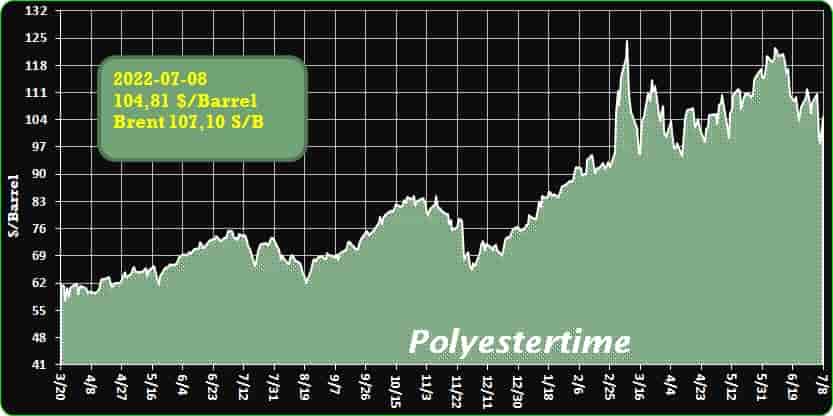

Crude Oil Prices Trend

-Collaboration Creates Recycling Loop for Multilayer PET

Water-based adhesive makes packaging film easier to delaminate.

The European Green Deal requires all packaging to be reusable or recyclable by 2030. The regulation is perceived as particularly challenging for multilayer packaging, since its layers first need to be separated before entering recycling streams.

A multilayer film produced by Evertis, comprising PET and PE layers, laminated with a BASF Epotal water-based adhesive and processed with a Bobst coating system, is produced for various applications, including thermo-formed food trays. After use, collected product can be used as a raw material by Sulayr. Sulayr has a process for separating the layers, recovering the PET for delivery to Evertis and other film producers. The process can be applied to both post-consumer and post-industrial product.

Sulayr has been able to separate multilayers since 2009, but the speed and cost-effectiveness depends on the debonding of the films. The new Epotal® water-based adhesive from BASF simplifies the process, enabling quicker and easier separation than is possible with solvent-based adhesives. Recycling-Loop – PA66-low-carbon-hydrogen

-PA66 from low carbon hydrogen

DOMO Chemicals and Hynamics collaborate on the HyDom project for the production of polyamides starting from low-carbon hydrogen.

domo impiant0 The Belgian producer of polyamides DOMO Chemicals has signed an agreement with Hynamics, a company of the EDF group specialized in the production of low-carbon hydrogen, in order to reduce the environmental impact of the Belle-Étoile industrial center in Saint-Fons. (near Lyon), in the heart of the Vallée de la Chimie in France. Recycling-Loop – PA66-low-carbon-hydrogen

As part of the HyDom project, a new 85 megawatt (MW) hydrogen production plant will be installed at the French site, through water electrolysis, with a production capacity of 11,000 tons of low environmental impact hydrogen, powered by energy renewable.

When it comes into operation in 2027, the new unit will cover the entire annual requirement of hexamethylenediamine production, a key component of polyamide 66, avoiding the emission of 84 thousand tons of carbon dioxide per year. It will replace an existing hydrogen production unit running on natural gas.

The project, supported by the France 2030 investment plan, represents an important step towards the decarbonisation of industrial sites that use gray hydrogen, obtained from fossil fuels. It was also presented to the European Commission for public funding.

-Lanxess Adds Sustainable Variants to Tepex Composites Range

Development of a composite with a polyamide 6 matrix containing more than 80% of sustainable raw materials is almost completed.

Lanxess is placing an emphasis on sustainability in its business activities, and new Tepex thermoplastic composites currently being developed based on recycled or bio-based raw materials are the latest example. “With these construction materials, we want to help our customers to make more sustainable products that have a smaller carbon footprint, conserve resources, and protect the climate,” explains Dr. Dirk Bonefeld, Head of Global Product Management and Marketing for Tepex at Lanxess. Recently, the specialty chemicals company launched a fully bio-based composite material based on flax and polylactic acid. Recycling-Loop – PA66-low-carbon-hydrogen

Development is about to be completed, for example, on a matrix plastic based on polyamide 6 for Tepex dynalite that is produced starting from “green” cyclohexane and comprises more than 80% of sustainable raw materials. The plastic meets the requirements that Lanxess has set for its new Scopeblue range — products that contain a significant proportion of circular (recycled or bio-based) raw materials or have a considerably smaller carbon footprint than their counterparts.

When the matrix plastic is reinforced with continuous-fiber fabrics, the resulting semi-finished products exhibit the same properties as comparable, equivalent fossil-fuel-based products. The semi-finished products with a green matrix are suitable for applications in structural lightweight designs that are typical for Tepex dynalite, such as front-end carriers, seat shells, or battery consoles.

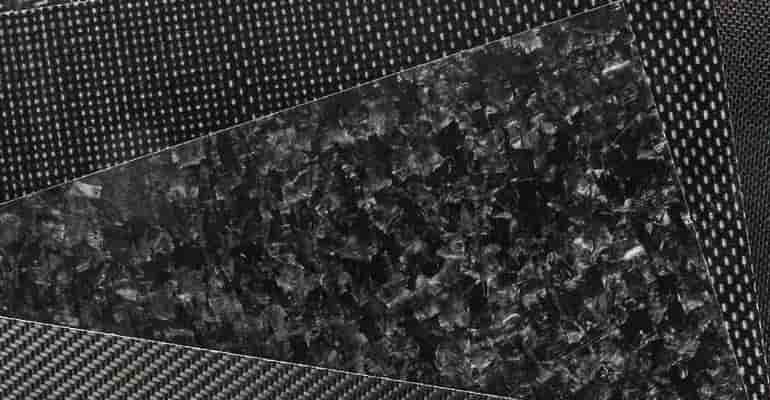

Bundling high-class décor and high-grade mechanical properties

Another new product line comprises variants of Tepex with up to 80% recycled material that yield surfaces with a so-called forged carbon look. The corresponding components feature a grain that is reminiscent of marble. The high proportion of recycled material is based on carbon fibers from post-consumer and post-industrial waste. The fibers are used as non-woven material or chopped fiber mats.

A variety of thermoplastics are suitable as a matrix material, such as polyamide 6 and 66, polypropylene, or polycarbonate, whereby types of recycled material made up of these plastics can also be used. Recycling-Loop – PA66-low-carbon-hydrogen

-Heartland Polymers Starts Polypropylene Production

Canadian company expects to produce more than 575,000 tons of PP annually, filling approximately 18 rail cars per day, seven days a week.

Heartland Polymers has successfully commissioned its polypropylene (PP) plant and began initial production at the Heartland Petrochemical Complex in Alberta, Canada. Railcars are being loaded with North America’s newest source of PP using Alberta, Canada-based propylene feedstock. Recycling-Loop – PA66-low-carbon-hydrogen

“A safe commissioning of our polypropylene plant is a crucial step towards commercial production of Heartland Polymers,” said Jim Madro, Senior Vice President, Petrochemicals. “The PP Plant has been producing pellets since late June with polymer grade propylene (PGP) from our storage cavern. The entire Heartland Complex remains on schedule for an integrated start-up in the third quarter of this year, at which point Heartland will begin commercial production.”

Heartland Polymers will initially produce homopolymers with plans to add random copolymers in 2023. Once commercial production is underway, Heartland is expected to produce 525,000 tonnes/578,713 tons of PP annually, filling approximately 18 rail cars per day, seven days a week.

“Heartland Polymers is anticipated to be one of the most reliable, service-oriented polypropylene producers in the industry,” says Yonas Kebede, director, polypropylene sales and marketing. “We have rail connections to every major shipping hub in North America, storage-in-transit to expedite delivery times, real-time GPS shipment tracking, and our geographic location means we are less vulnerable to extreme weather incidents that can cause downtime, additionally we have reliable access to one of the world’s largest sources of propane feedstock.” Recycling-Loop – PA66-low-carbon-hydrogen

-U.S. factory activity slows to two-year low as clouds gather over economy

U.S. manufacturing activity slowed more than expected in June, with a measure of new orders contracting for the first time in two years, signs that the economy was cooling amid aggressive monetary policy tightening by the Federal Reserve, said Reuters.

“The June Manufacturing PMI registered 53 percent, down 3.1 percentage points from the reading of 56.1 percent in May. Recycling-Loop – PA66-low-carbon-hydrogen

This figure indicates expansion in the overall economy for the 25th month in a row after a contraction in April and May 2020. This is the lowest Manufacturing PMI® reading since June 2020, when it registered 52.4 percent. The New Orders Index reading of 49.2 percent is 5.9 percentage points lower than the 55.1 percent recorded in May. The Production Index reading of 54.9 percent is a 0.7-percentage point increase compared to May’s figure of 54.2 percent. The Prices Index registered 78.5 percent, down 3.7 percentage points compared to the May figure of 82.2 percent. The Backlog of Orders Index registered 53.2 percent, 5.5 percentage points below the May reading of 58.7 percent. The Employment Index contracted for a second straight month at 47.3 percent, 2.3 percentage points lower than the 49.6 percent recorded in May. The Supplier Deliveries Index reading of 57.3 percent is 8.4 percentage points lower than the May figure of 65.7 percent. The Inventories Index registered 56 percent, 0.1 percentage point higher than the May reading of 55.9 percent. The New Export Orders Index reading of 50.7 percent is down 2.2 percentage points compared to May’s figure of 52.9 percent. The Imports Index climbed into expansion territory, up 2 percentage points to 50.7 percent from 48.7 percent in May.”

“All of the six biggest manufacturing industries — Computer & Electronic Products; Machinery; Transportation Equipment; Petroleum & Coal Products; Food, Beverage & Tobacco Products; and Chemical Products — registered moderate-to-strong growth in June. Recycling-Loop – PA66-low-carbon-hydrogen

-Over 2 billion plastic bottles recovered for recycling in SA

STATISTICS from South Africa’s longest-standing plastics producer responsibility organisation indicate that the country’s PET plastic recycling rates are recovering after the lockdown regulations resulting from the Covid-19 pandemic.

According to figures released at the PET Recycling Company’s (PETCO) annual general meeting in June, 2.1 billion PET bottles were diverted from landfill last year thanks to the various recycling efforts in which it was involved. Recycling-Loop – PA66-low-carbon-hydrogen

On the back of waste management experts warning that parts of South Africa could soon run out of landfill space, CEO Cheri Scholtz said PETCO’s efforts had saved an area equivalent to 560 495 cubic metres and prevented potential associated carbon emissions of 135 604 tonnes in 2021.

Despite a challenging year for the paper and packaging sector, PETCO, which represents producers of polyethylene terephthalate (PET) packaging, grew its collection of post-consumer PET bottles for recycling by 14% – from 79 078 tonnes in 2020 to 90 402 tonnes in 2021.

“In spite of the impact of prolonged Covid-19 lockdowns and curfews on collection rates, which restricted the movement of informal collectors, 63% of PET packaging that was placed on the market by PETCO members was collected for recycling in 2021,” Scholtz said.

“Once lockdown regulations eased, PETCO made a concerted effort to stimulate collection by supporting informal waste pickers and formal collection businesses, buy-back centres, and recyclers, and encouraging them to grow capacity and capability.”

STATISTICS from South Africa’s longest-standing plastics producer responsibility organisation indicate that the country’s PET plastic recycling rates are recovering after the lockdown regulations resulting from the Covid-19 pandemic.

According to figures released at the PET Recycling Company’s (PETCO) annual general meeting in June, 2.1 billion PET bottles were diverted from landfill last year thanks to the various recycling efforts in which it was involved.

On the back of waste management experts warning that parts of South Africa could soon run out of landfill space, CEO Cheri Scholtz said PETCO’s efforts had saved an area equivalent to 560 495 cubic metres and prevented potential associated carbon emissions of 135 604 tonnes in 2021.

Despite a challenging year for the paper and packaging sector, PETCO, which represents producers of polyethylene terephthalate (PET) packaging, grew its collection of post-consumer PET bottles for recycling by 14% – from 79 078 tonnes in 2020 to 90 402 tonnes in 2021.

“In spite of the impact of prolonged Covid-19 lockdowns and curfews on collection rates, which restricted the movement of informal collectors, 63% of PET packaging that was placed on the market by PETCO members was collected for recycling in 2021,” Scholtz said. Recycling-Loop – PA66-low-carbon-hydrogen

“Once lockdown regulations eased, PETCO made a concerted effort to stimulate collection by supporting informal waste pickers and formal collection businesses, buy-back centres, and recyclers, and encouraging them to grow capacity and capability.”

Prices on July 2 for film HDPE were announced at 21,630 Indonesian rupees per kg, DEL Java, while on June 25 they were 21,760 rupees per kg, DEL Java.

LDL offerings for July 2 were announced at Rs 21.34 per kg del Java compared to Rs 22.06 per kg del Java on June 25. Recycling-Loop – PA66-low-carbon-hydrogen

The reasons for the price increase were not called, but market participants said that prices followed the continuing decline in prices for imports of polyethylene in Southeast Asia.

Earlier it was reported that a major Indonesian supplier raised prices for linear low-density polyethylene (LDL) and film low-pressure polyethylene (HDPE) for its domestic customers. Prices on June 25 for film HDPE were announced at 21,760 Indonesian rupees per kg, DEL Java, while on June 18 they were 21,550 rupees per kg, DEL Java.

-Asia petchems mired in bearishness on elevated recession fears

Asian petrochemical markets are in a jam, with price bearishness across the board as recession risks continue to mount.

Elevated concerns on the economic front, from the fallout of the Russia-Ukraine conflict and sanctions on Russia, plus fears of upward spiralling inflation continue to weigh on sentiment. Recycling-Loop – PA66-low-carbon-hydrogen

The increase in interest rates from central banks to combat inflationary pressures around the world has also fanned concerns of sending the world into a recession.

In addition, it would be a long shot for markets to look to support from China, the world’s second-largest economy.

Supply recovery coupled with slow demand recovery led to an overall decline in China’s petrochemical market in June.

In early June, the market jumped quickly on the back of stimulus policies but has since retreated.

Compared with the end of May, the ICIS China Petrochemical Price Index fell 3.8%, to 1374.99 at the end of June.

Downstream by product, Asia’s monoethylene glycol (MEG) market plunged to its lowest level this week since the end of 2020, as the crude slump and weak downstream demand exerted downward pressure on spot discussions.

Polyester producers have started a new round of production cuts after reducing operations in April due to COVID-19 lockdowns in Shanghai, as end-demand remained sluggish amid global inflation and recession concerns. Recycling-Loop – PA66-low-carbon-hydrogen

Recycling-Loop – PA66-low-carbon-hydrogen