Recycling PETBottle BiodegradablePlastics 09-04-2021 - Arhive

Recycling PETBottle BiodegradablePlastics

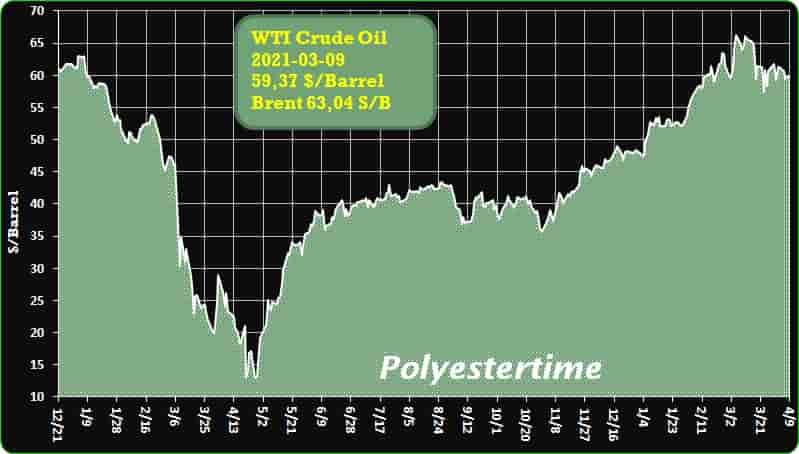

Crude Oil Prices Trend

-Starlinger Viscotec technology aids in PET thermoform recycling

The deCON iV+ decontamination dryer increases the IV of PET flakes produced from recycling thermoformed containers.

While demand is strong for polyethylene terephthalate (PET) bottle flakes, that is not yet the case for PET flakes made from thermoformed containers. In the U.S., roughly 15 percent of PET thermoformed materials, such as clamshells, cups, trays and boxes, are recovered from the recycling stream, according to American Starlinger-Sahm Inc., Fountain Inn, South Carolina.

“In the North American market, postconsumer thermoforms are generally not captured in the PET recycling stream,” says Jeff Cornell, vice president of sales at American Starlinger-Sahm. “This is changing with new legislation and improved technologies to sort out this valuable material.”

Because PET thermoforms have a lower intrinsic viscosity (IV) than PET bottles and are amorphous, the material needs pretreatment, the company says.

-Asia PE, benzene supply tight on firm demand, economic recovery

Asia’s supply of polyethylene (PE) and benzene is tight amid plant shutdowns among suppliers in the face of rising demand as the region’s pace of economic recovery strengthens.

The International Monetary Fund (IMF) upgraded the 2021 growth forecast for emerging and developing Asian economies to 8.6%, reflecting a stronger recovery than initially expected after lockdowns were eased in some large countries.

For southeast Asia, PE import supply is likely to remain tight for a few more weeks due to plant maintenance scheduled in April and May, particularly in Thailand.

In India, a major producer is also due to shut its low density polyethylene (LDPE) plant for maintenance in April. Recycling PETBottle BiodegradablePlastics

Most other producers elsewhere in Asia, however, are not due for any shutdowns until mid-year.

“The import cargoes from the US might keep tight for [the] Asian market in April due to strong demand in the US, although more plants in the US resumed [production] from March,” said ICIS senior analyst Amy Yu.

-Unlocking Sustainability: Avient to Showcase Solutions for a Circular Economy at Chinaplas 2021

Avient Corporation will feature its portfolio of sustainable materials and colorant technologies at Chinaplas 2021.

These new and existing materials, additives, and colorants help to reduce energy use, increase the use of recycled content, and improve recycled material performance for applications in the packaging, automotive, healthcare, telecommunications, and consumer electronics industries. Recycling PETBottle BiodegradablePlastics

Say-Eng Lee, VP and GM, Color and Additives Asia, said: “From colour modelling to the latest advances in materials science, Avient is unlocking the potential of sustainability in Asia and globally. For example, our recently opened CycleWorks facility in Italy is providing cutting-edge support for the development of new and sustainable masterbatch formulations, many of which we will display at Chinaplas.”

-Commodity Resin Prices Rise, But PP Falls

Supply constraints continue to be a key factor in further resin price increases.

Continued strong demand and supply constraints in feedstocks and/or resins drove prices of PE, PS and PVC sharply up again, with prices of PET also higher. That supply/demand scenario applies even more so to PP, but monomer dropped by nearly 20¢/lb and PP followed suit to a point, as suppliers continued to issue monthly non-monomer price hikes. Recycling PETBottle BiodegradablePlastics

Some “price corrections” are likely this month or next as recovery of supplier inventories is expected for all the largest-volume commodity resins, except for PP. These are the views of purchasing consultants from Resin Technology, Inc. (RTi), senior editors at PetroChemWire (PCW), and CEO Michael Greenberg of The Plastics Exchange.

-Ampacet adds additives to production in Russia

New York-based Ampacet has expanded its plant in Tver, Russia. Additive production started up earlier this year.

Materials maker Ampacet Corp. has added production of plastic additives at its plant in Tver, Russia. Recycling PETBottle BiodegradablePlastics

Tarrytown, N.Y.-based Ampacet began production of those materials at the site early this year, officials said in a news release. They said the new line features the latest technology in additives production and was engineered with a focus on safety, ergonomics and environmental impact.

Energy and water systems have been designed to produce minimal environmental impact at the site, officials added.

“Our deep knowledge of the Russian market, together with Ampacet’s innovative products, allow us to meet regional customer needs,” Russia general manager Alexei Fomtsov said in the release.

Ampacet has operated in Russia since 2008, when it began production of color concentrates. Officials said that localizing the color business “has met with tremendous success,” helping Ampacet to become the leader in the Russian color concentrates market with more than 1,200 customers.

The Russian market “is growing rapidly and local presence is key to providing the proper service to our customers,” Europe managing director Marcello Bergamo added.

Ampacet’s expansion in Russia is the latest in a series of European moves for the firm. In 2017, Ampacet started a new color concentrates production line in Dudelange, Luxembourg. In 2018, the firm opened a new additive production line in Messancy, Belgium. Additional lines doubled the firm’s color concentrates capacity in Dudelange in 2019.

-SULZER CHEMTECH AND BOREALIS DEVELOP NEW EXTRUSION PROCESS FOR EXPANDED PP

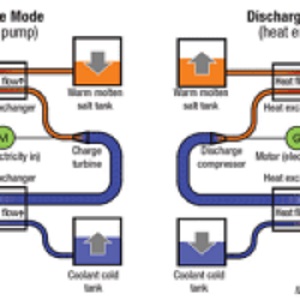

Sulzer Chemtech Ltd. (Winterthur, Switzerland) and Borealis Group AG (Vienna, Austria) have completed the development of an innovative process for the cost-effective extrusion of expanded polypropylene (ePP) beads.

Polypropylene (PP) is a highly effective material, offering advanced mechanical properties and being well suited for reusing and recycling. To support the large-scale adoption of ePP, Sulzer Chemtech is now launching a new and innovative production line. Developed together with raw material supplier Borealis, the resulting solution supports the end market efforts towards more circular solutions and is expected to cut manufacturing costs by up to 60%. Recycling PETBottle BiodegradablePlastics

As opposed to conventional autoclave production methods, Sulzer Chemtech’s innovative system relies on extrusion with direct gas impregnation, offering an easy to implement alternative with a quick return on investment. Foam molders, such as packaging manufacturers, can implement the compounding line to considerably reduce the costs associated with material supply, warehousing and intermediate transportation. As a result, companies can offer ePP parts at more competitive prices while supporting the adoption of easy to recycle polyolefin applications.

-Clearing up the bioplastic confusion

In clean and sterile environments there is a need for a lot of single-use consumables that contain plastic, but this poses an obvious environmental challenge. The categories of ‘green’ plastics can be confusing, and clarifying the terminology of these bioplastics is vital to their increased use in industry

It’s a bit of a cliché to say the world is changing but this has never been more true than in 2020. This year has put the spotlight on more things than a virus. The green agenda has at last been seen as a top priority for governments globally, and one of the biggest developments in industry in recent years that assists in “going green” is the uptake of biodegradables and related resources. This has been demonstrated by a steady rise in the use of bioplastics with its many applications. But the terminology within bioplastics can be confusing; so in this article we are going to demystify the language around plastics and related terminology that you are likely to see more often into 2021 and beyond. Recycling PETBottle BiodegradablePlastics

Here are some of the most common terms used on the subject.

Bio-sourced

Bio-based

Biodegradable

Compostable

Recyclable

Plant Based

-2021 Plastics Recycling Conference: Pandemic boosts resin demand

Demand increase has been met by supply constraints, improving margins.

The COVID-19 pandemic has increased demand for single-use packaging and personal protective equipment (PPE) made from plastics. At the same time, the supply of polyolefins, such as polypropylene, high-density polyethylene (HDPE) and polyethylene terephthalate (PET) have been reduced as hurricanes and winter weather have affected virgin production along the Gulf Coast.

Joel Morales, the Houston-based executive director of Polyolefins Americas at IHS Markit, said the pandemic resulted in a great deal of demand for polyethylene in 2020. Recycling PETBottle BiodegradablePlastics

Morales spoke during the Resin Market Update at the 2021 Plastics Recycling Conference, which is taking place online April 7-8.

While many industries braced for a “really bad year” in 2020 because of the pandemic, Morales said the opposite happened for a number of industries, including plastics, which contributed to pricing power and margin growth for virgin resin producers.

He added that he expects margin resiliency and pricing power in the virgin polyethylene (PE) sector to dissipate as new capacity begins to come online, with the impact expected to hit midyear.

Morales said sustainability “took a back seat in 2020” as protecting people from the coronavirus took priority, increasing consumption of single-use plastic packaging and demand for plastics used in hygiene and medical applications.

-Eissmann Automotive Absorbs Minda KTSN Plastic Solutions

The successful takeover of plastics expert KTSN and additional expertise positions the group as a technology integrator and more effective partner for customers in the automotive industry, said the company.

Eissmann Automotive KTSN GmbH announced today that it is now wholly part of the Eissmann Group and that the operational merger of Minda KTSN Plastic Solutions GmbH & Co. KG has been completed. The Minda subsidiary in Poland will be renamed Eissmann Automotive Polska Sp.zo.o. Robert Kozielski will head management of the Eissmann plant in Pirna, Germany, southeast of Dresden, and Jacek Stefański will continue as manager in Poland.

Eissmann Group reports that it was able to reach all closing conditions as planned on March 31. Recycling PETBottle BiodegradablePlastics

Minda KTSN was the German subsidiary of India’s auto parts maker Minda Corp. and had built a reputation for injection molding gloveboxes, seat-back panels, cup holders, and other plastic components for the automotive industry at plants in Pirna, Mexico, and Poland. It filed for bankruptcy protection in Germany in June 2020, after the parent company chose to stop investing capital, reported The Hindu newspaper at the time.

-Celanese expands Asian compounding capacity; adding on UHMW-PE and acetyls capacities globally

Chemical firm Celanese Corporation has announced a number of initiatives to increase its capacity globally. The first of this is to initiate a three-year plan to expand engineered materials compounding capacities at the company’s Asia facilities, including the locations of Nanjing, China; Suzhou, China; and Silvassa, India.

To support the significant business growth expected, Celanese has begun planning for the following Asia expansion investments:

- i) Nanjing, China compounding and LFT expansion: the intended scope of this project adds approximately 52 kilotonnes of compounding and long-fibre thermoplastics (LFT) capacity at the company’s Nanjing integrated chemical complex by the second half of 2023. Recycling PETBottle BiodegradablePlastics

- ii) Suzhou, China nylon expansion: the intended scope of this project adds approximately 7 kilotonnes of nylon compounding capacity at the company’s Suzhou facility by the second quarter of 2022.

Recycling PETBottle BiodegradablePlastics