Plastics Production

“The right choice for your production”

Bright-chip rPET – Reliance Industries pioneers chemical recycling of plastic waste into certified circular polymers

More…

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

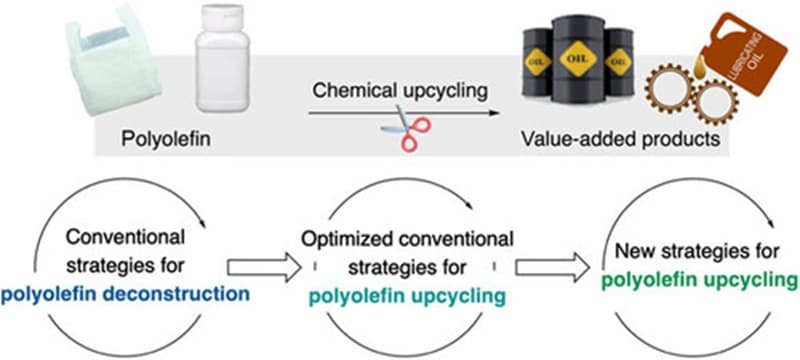

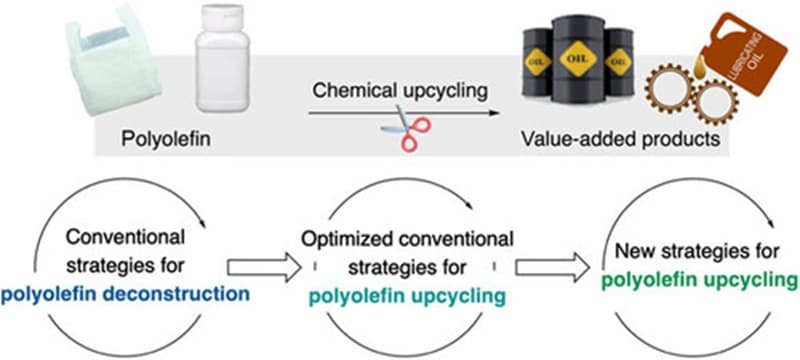

Beyond Conventional Degradation: Catalytic Solutions for Polyolefin Upcycling

Polyolefins (POs, i.e., polyethylenes, ethylene/α-olefin copolymers, and polypropylenes) are the most ubiquitous synthetic macromolecular materials in modern life. Their widespread use and low recovery rate after extensive usage have caused significant resource waste and environmental concerns. Chemical recycling of POs provides an efficient approach to unravelling the polymer chain to various chemicals. However, conventional chemical recycling methods, including pyrolysis, hydrocracking, and oxidation, require high-energy input (typically >500 °C) and/or the use of environmentally unfriendly chemicals, leading to complex product distribution. Plastics Production

In this minireview, based on recent representative works, we summarize and highlight catalytic strategies addressing these issues in PO recycling from two perspectives: (1) employing advanced catalysts or technique designs to overcome the challenges in conventional chemical deconstruction approaches; and (2) developing novel tandem/cascade catalytic systems for highly selective PO upcycling under relatively mild conditions. We hope that this minireview will help researchers better understand the state of the art of PO chemical recycling and inspire more innovative and efficient ideas for this fast-developing field.

Introduction

Due to its durability and relatively low production cost, plastic has become one of the most ubiquitous synthetic materials in our modern world. Plastics Production

More…

Russia Witnesses 11.3% Surge in Plastics Production Over Four Months

Over the course of 11 months in 2023, Russia has witnessed a noteworthy uptick in the production of plastics in primary forms, marking a 3.4% increase compared to the corresponding period in the previous year. This positive trajectory is primarily fueled by heightened production levels of polyethylene (PE) and formaldehyde resins, although the recent months have seen a somewhat less substantial increase in PE, standing at 1.8%. Nevertheless, the sheer volume of PE produced, surpassing other polymers, has contributed to an overall favorable trend in the broader plastics category.

The surge in the production of formaldehyde resins has been more pronounced, exhibiting a robust 9.6% increase over the 11-month period. Plastics Production

Notably, this escalation in output began in September, with figures for the preceding eight months trailing behind the results recorded in the same period of the previous year.

On the flip side, the production of polyvinyl chloride (PVC) has shown signs of improvement. While the volume of PVC production at the end of nine months was 2022.6% lower than the figures from the previous year’s six-month results, by the conclusion of the 11-month period, they essentially equalled the levels recorded in the corresponding period of the prior year.

In contrast, polyamides remain on the lower end of the spectrum, experiencing a substantial decline of 20.2% over the 11-month period compared to the same period in the previous year. Plastics Production

More…

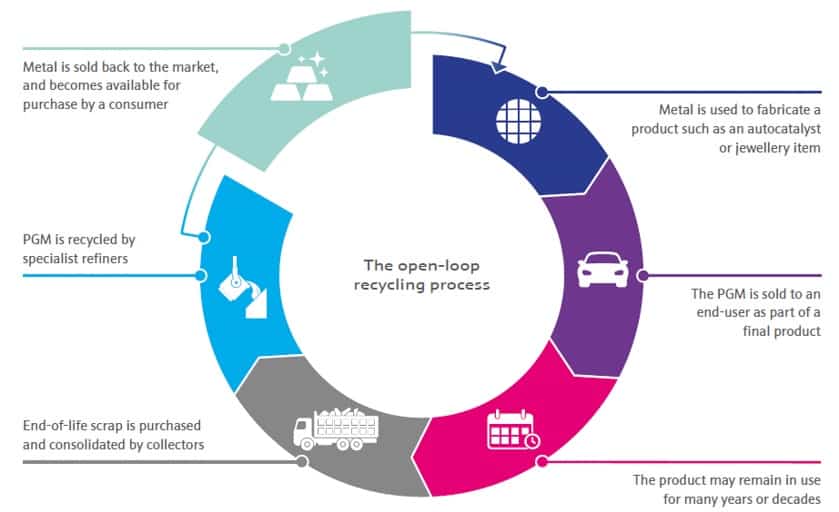

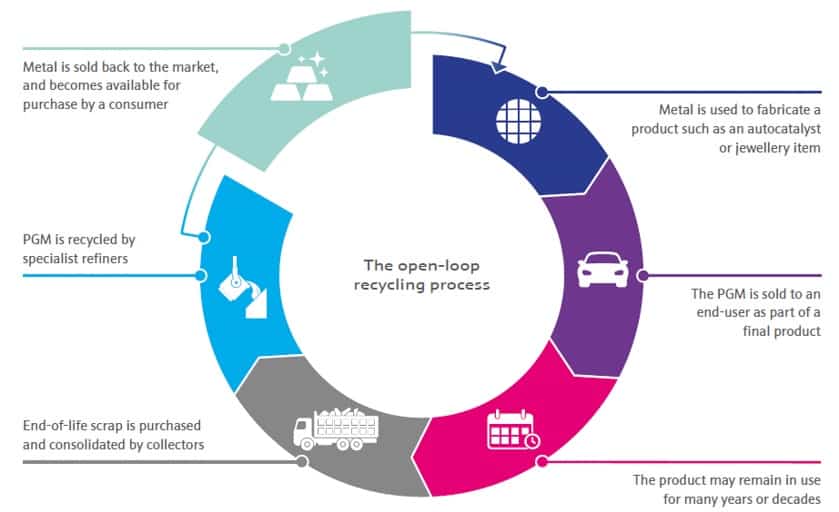

Secondary supplies and importance of recycling

PGMs are valuable due to their unique properties and rarity. Because of this, recycling (also known as secondary supplies) is critical to conserve these precious resources and meet market demand.

Depending on the application, most PGMs are recoverable through the product lifecycle. Once recycled, secondary PGM has exactly the same properties as primary PGM, so ost of the PGM mined to date is still either in use or in a useable form. Plastics Production

PGMs are reused in two ways:

Open-loop recycling

The original purchaser of the metal does not retain control of the PGM, so the metal is available to the market once recovered. It contributes to market supply and helps bridge the gap between supply and demand.

Closed-loop recycling

Metal is retained within the same application by the same owner. For example, PGM recycled from spent chemical catalyst used make fresh catalyst to replace it. Because the net amount of metal in use has not changed, the ‘returned’ metal does not count as market supply, but it reduces the need for fresh metal to be purchased and therefore makes demand more sustainable. Plastics Production

Recycled Polyolefins Close Year Up From Fall Lows

Pledges to incorporate recycled polymer materials did not translate into increased prices for the commodity in 2023, with prices generally falling for all grades and types of reclaimed and reprocessed materials. According to weekly reports from Oil Price Information Service (OPIS), many prices peaked in May/June and fell sharply in August. Prices for polyolefin materials rose somewhat from September through December.

PE scrap prices rose early in the year, fell and then recovered somewhat. Reprocessed PE grades and PP exhibited similar pricing trends. Photo Credits: Adapted from OPIS weekly reports. Plastics Production

Recycled PP also found higher prices toward the end of the year.

Prices of Polyester Bales and Reprocessed Materials Fall

Bottle grade PET fell most dramatically, from 88 cents/lb in January to 56 cents/lb in December. Reprocessed FDA clear PET also declined significantly, while other grades of bales and regrind remained relatively flat.

Price movement in scrap and reprocessed polyethylene terepthalate (PET) varied by grade, but were generally flat or down for the year. Plastics Production

More…

Battery Recycling: Understanding Core Charges

What is a Core Charge?

A core charge is a deposit that is levied when purchasing certain automotive parts, including batteries, with the intention of encouraging the return of the old or used part for recycling. In the context of battery recycling, when a consumer purchases a new battery, they are often required to pay a core charge, which acts as a deposit or incentive to ensure the return of the old battery for proper recycling. This practice is prevalent in the automotive industry and is aimed at promoting environmental responsibility by facilitating the collection and recycling of used batteries. Plastics Production

The core charge is essentially a refundable deposit that serves as an incentive for consumers to return their old batteries for recycling rather than disposing of them improperly. It is important to note that the core charge is typically included in the initial purchase price of the new battery, and the amount varies based on the type and model of the battery. Once the old battery is returned, the core charge is refunded to the consumer, provided that the returned battery meets the required criteria for recycling.

When purchasing a new battery, consumers should expect to see the core charge listed as a separate line item on their invoice or receipt. This transparent approach ensures that consumers are aware of the deposit and its purpose, thereby promoting accountability and environmental stewardship. Plastics Production

The concept of core charges aligns with the principles of a circular economy, where products and materials are reused, recycled, or repurposed to minimize waste and reduce environmental impact. By incorporating core charges into the purchase of automotive batteries, manufacturers and retailers actively participate in promoting sustainable practices and encouraging the responsible disposal and recycling of used batteries.

More…

Biomass-derived PET – Garware Technical Fibres has introduced an innovative coatable High-Density Polyethylene (HDPE) braided knotted net, marking a significant milestone in the industry 30-12-2023

Plastics Production