Adipic-Acid – Plastic – Automotive 26-08-2022 - Arhive

Adipic-Acid – Plastic – Automotive

Crude Oil Prices Trend

-Toray Develops Bio-Based Adipic Acid

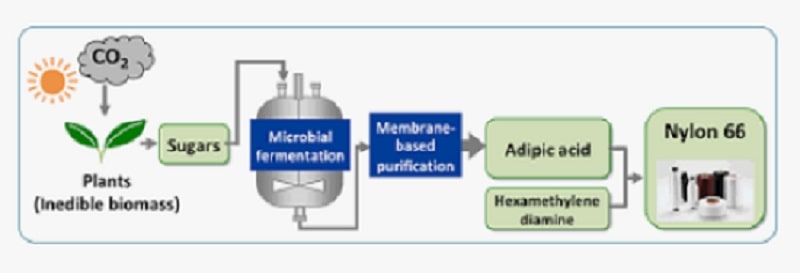

Toray Industries, Inc. has developed 100% bio-based adipic acid, a raw material for nylon 6,6 (polyamide 66), from sugars derived from inedible biomass. This achievement came from using a proprietary synthesis technique combining the company’s microbial fermentation technology and chemical purification technology that harnesses separation membranes.

The company has started to scale up its capabilities in this area. It will test polymerization of nylon 6,6, develop production technology, conduct market research, and take steps to commercialize applications for this bio-based adipic acid by around 2030.

Nylon 6,6 has been used for many years in fibers, resins, and other applications due to its exceptionally durable, strong, and rigid properties. Pressures to develop eco-friendly nylon 6,6 have risen in recent years amid a growing awareness of the need to realize a sustainable society. One challenge is that conventional chemical synthesis for producing adipic acid, the raw material of nylon 6,6, generates a greenhouse gas called dinitrogen monoxide. Adipic-Acid – Plastic – Automotive

Toray discovered microorganisms that produce an adipic acid intermediate from sugars. The company reconfigured metabolic pathways within microorganisms to enhance production efficiency by applying genetic engineering technology, which artificially recombines genes to streamline synthesis in microorganisms. It also employed bioinformatics technologies to design optimal microbial fermentation pathways for synthesis. Quantity of the intermediate synthesized by microorganisms has increased more than 1,000-fold since the initial discovery, and the efficiency of synthesis has improved dramatically.

In the wild world of plastics, there are many more types than the layperson might realise. And while most are recyclable, not all are. Some ingredients are not worth recycling. And both chemical and mechanical recycling have their pros and cons. Let’s take a deep dive into how it all works.

Being in the recycling industry, I often get asked questions like:

- Are all plastics recyclable?

- Can you use 100 per cent recycled plastics to make new bottles?

- Can you recycle plastics indefinitely?

- How many times can you recycle plastic?

So far so good. But then most people expect clear and simple answers, and that’s where the problem lies. Adipic-Acid – Plastic – Automotive

The right answer to most of the above questions is: “it depends”.

Or, to say it with American journalist Henry Louis Mencken: “for every complex problem, there is a solution that is neat, plausible, and wrong.”

Not all plastics are created equal and recycling does not equal recycling. But, because I get asked these questions quite a lot, here are some relatively simple answers.

Most plastics are recyclable, but not all ingredients within a plastic product may be recyclable and not all plastics are worth recycling.

What does this mean, you ask? Well, think about the pigments of colour used to make coloured plastic. We can recycle the plastic, and we can get rid of the pigment, but we typically cannot or do not recycle the pigments. The main reason is that it’s just not viable to do so.

-Bundesbank says recession in Germany increasingly likely

Germany is increasingly likely to witness a recession with accelerating inflation, which could peak at more than 10 per cent this autumn, according to the Bundesbank, which said in a monthly report recently that the high degree of uncertainty over gas supplies this winter and the sharp price rise are likely to weigh heavily on households and companies.

As energy costs keep pushing inflation higher, a peak is unlikely before the autumn at around five times the European Central Bank’s 2 per cent target.

“Declining economic output in the winter months has become much more likely,” the central bank said. Adipic-Acid – Plastic – Automotive

The likelihood of a recession is widely attributed to Russia curtailing gas exports to Germany in response to Western sanctions over the former’s war in Ukraine.

The country is already forced to curtail consumption, with energy-intensive sectors suffering heavily.

“The upside risk for inflation is high, in particular in the event of a complete stoppage of gas supplies from Russia,” the Bundesbank said.

-Resin Price Report: Spot Prices Drop as Producers Struggle to Move Inventory

Producers remain under pressure as resin storage costs rise, empty railcars are hard to find, and new capacity is poised to come online.

The dog days of summer are living up to their name in the commodity resin trading market, at least for sellers. Resin prices continued their downward trek the week of August 15, after taking a short-lived sabbatical just a week earlier. Additional industry data released this week reminded the market that long-supply/weak-demand fundamentals continue to weigh on the polyethylene (PE) and polypropylene (PP) markets, as do continued global economic concerns, reported the PlasticsExchange in its Market Update. This has made buyers reluctant to make large purchases, and overall slack demand provides buyers with leverage to push for lower prices.

The drop in spot levels also comes as producers remain under pressure to clear out material as storage costs rise, empty railcar availability is limited, and brand-new production capacity is set to come online over the next three to four months. The overhang of material remains a heavy burden on producers looking to reduce stockpiles. Resellers that desire reduced on-hand inventories continue to offer spot cars back into the market. Adipic-Acid – Plastic – Automotive

The dog days of summer are living up to their name in the commodity resin trading market, at least for sellers. Resin prices continued their downward trek the week of August 15, after taking a short-lived sabbatical just a week earlier. Additional industry data released this week reminded the market that long-supply/weak-demand fundamentals continue to weigh on the polyethylene (PE) and polypropylene (PP) markets, as do continued global economic concerns, reported the PlasticsExchange in its Market Update. This has made buyers reluctant to make large purchases, and overall slack demand provides buyers with leverage to push for lower prices.

The drop in spot levels also comes as producers remain under pressure to clear out material as storage costs rise, empty railcar availability is limited, and brand-new production capacity is set to come online over the next three to four months. The overhang of material remains a heavy burden on producers looking to reduce stockpiles. Resellers that desire reduced on-hand inventories continue to offer spot cars back into the market.

Yet, resin price increases remain on the table

In the meantime, price increases remain on the table, at least for PE, as a protective measure, especially as hurricane season typically is at its most dangerous in the late third quarter and early fourth quarter. Logistics issues persist, as well, with a rail embargo in California still in place and extended lead times needed at the port. Rail congestion has the potential to become even more of an issue, if rail worker unions and rail carriers cannot come to a new labor agreement by Sept. 16. Houston warehouse packaging schedules are backed up with some rail holding tracts already full. This has all placed extra demand for ready-to-go truckloads.

As we near the end of the month, present spot levels point to an August contract increase of around $0.02/lb, according to the Chicago-based resin clearinghouse. That would be the first contract increase since March.

PE resin trading stalls

PE resin trading activity stalled last week as buyers continue to wait for better bargains ahead. The two-cent drop in spot PE commodity-grade prices also came with a decline in completed orders at the PlasticsExchange trading desk, although a good number of inquiries still came in. A steady flow of off-grade railcar offers showed up in the domestic market, while plenty of prime PE was available for certified export at deeply discounted prices. Some processors were out seeking prime truckloads for immediate shipment at off-grade railcar pricing, but suppliers kept their arms folded. Adipic-Acid – Plastic – Automotive

-Microban Launches Industry Groundbreaking Antimicrobial Technology For Cotton

Introducing DuraTech™ by Microban®: a non-heavy metal antimicrobial cotton technology with superior wash durability

Microban International is pleased to unveil its new, game-changing technology – DuraTech™ by Microban® – an antimicrobial additive with superior wash durability designed explicitly for cotton applications. This ground-breaking non-heavy metal technology helps to prevent the growth of odor-causing bacteria up to 99.99 percent after 75 home launderings which far exceeds industry standards. DuraTech also works to keep cotton fabrics fresher for longer by reducing odors up to 99 percent even after 75 home launderings. Adipic-Acid – Plastic – Automotive

This innovation from the global leader in antimicrobial and odor control solutions is part of Microban’s continued commitment to being a sustainability-solutions focused company. DuraTech will push the boundaries of antimicrobial cotton technology, addressing the needs of brands and manufacturers for a more durable and sustainable solution through the elimination of heavy metals from the formulation. As well as being a non-heavy metal antimicrobial, DuraTech is also binder-free, non-ionic, and fully water soluble. These features allow DuraTech to easily integrate into cotton fabrics during normal padding manufacturing processes, with no impact on the appearance or feel of the final cotton product. DuraTech works continuously to protect cotton products from the growth of harmful bacteria, which can lead to unpleasant odors, stains, and early product deterioration.

DuraTech will be available to cotton fabric manufacturers and brands in the U.S. and Asia, and will include Microban’s invaluable turnkey support services for branded partners. This novel technology is perfect for creating antimicrobial cotton products, such as sheets and towels for home textiles, hospitality, apparel, and more.

-Polyplastics Expands Engineering Plastics Supply for Automotive, Electronics, Medical

New capacity for polyacetal, LCP, and COC is complemented by a tech center in Germany to bolster the Japan-based company’s European presence.

Japan’s Polyplastics Group will highlight its expanded engineering thermoplastics portfolio and material supply capabilities at the upcoming K 2022 exhibition in Düsseldorf, Germany. The company will discuss the latest developments in its Duracon POM, Laperos LCP, and Topas COC product lines, which address demanding end-use requirements in the medical, electrical/electronics, and automotive industries.

With full acquisition by Daicel in 2020, Polyplastics has expanded its options for growth and geographical market coverage. The company has increased liquid crystal polymer (LCP) sales to Europe, the Middle East, Africa, and the Americas while making timely investments in capacity to better respond to market growth.

German tech center supports EU customer base

Polyplastics’ Technical Solutions Center in Raunheim, Germany, officially opened in April. The one-stop shop serves the technical support needs of its growing customer base in Europe. Adipic-Acid – Plastic – Automotive

“This investment reaffirms our continued commitment to the engineering plastics market in Europe,” said Yohei Iizuka, Managing Director of Polyplastics Europe GmbH. “The new technical service operation will support application development work and enable our customers to shape their innovations from concept to commercialization.”

The company has installed an injection molding machine to facilitate customer molding trials, improve processing issues, and support application development and other collaborative projects. A new showroom showcases Polyplastics’ leading-edge technologies, advanced concepts, and new materials. The showroom also provides space for customer seminars.

-Covestro building PC recycling capacity in Shanghai

Investing in production of more sustainable polycarbonates in Asia Pacific

With the transition toward a circular economy in progress, Covestro is now taking further steps to increase its recycling activities at two of its sites in the Asia Pacific region.

The company has now announced plans to set up its first dedicated line for the mechanical recycling (MCR) of polycarbonates at its integrated site in Shanghai; but it will also be repurposing an existing compounding line at its Map Ta Phut site in Thailand to a plant for mechanical recycling. Adipic-Acid – Plastic – Automotive

After completion, the two facilities will boost Covestro’s output of post consumer recycled polycarbonates Makrolon R and Bayblend R. These Makrolon grades contain up to 75 percent recycled content and can contribute to a carbon footprint reduction of up to 50 percent while meeting performance and eco-labels’ requirements.

The line at the Shanghai site represents an investment of more than €27 million and, once it is commissioned in 2023, will deliver more than 25,000 tons of high-quality polycarbonates and blends containing mechanically recycled content annually. The input for the line will be post-consumer-recycled products, to be used primarily for the compounding step in the manufacture of electrical and electronic products, automotive applications, and consumer goods.

Overall, the company aims to be capable to deliver more than 60,000 tons of polycarbonates with recycled content in Asia Pacific per year until 2026.

-Why PP market still depressed amid intensive shutdown?

As of late August, PP market still does not have a relatively clear expectation for improvement. Although PP market has been supported by the plant maintenance, it is still sluggish, and market mindset is confused.

First, support from the supply side.

However, even supported by the plant maintenance, the market is still sluggish. It is believed that the main important factor is the lack of downstream demand. First of all, the repeated outbreak of the epidemic has seriously restricted downstream demand and logistics and transportation. Second, there have been continuous high temperature weather in many places this year, and there is a large gap in power supply. Power rationing policies have been implemented in many places, requiring industrial enterprises to stagger production during peak load times, mainly in Sichuan and Chongqing and Jiangsu and Zhejiang. Taking the BOPP industry as an example, BOPP can be said to be relatively healthy in the downstream of PP, but there has also been a decline in operating rate and orders recently, which shows that the current downstream demand is not enough to support the upward trend of the market. Adipic-Acid – Plastic – Automotive

Third, whether the peak season can be expected.

The golden September and silver October is coming soon, and many market participators are wondering whether the peak season can come. The traditional off-season is coming to an end. Also, with the relief of high temperature in the future, the power rationing policy is expected to be cancelled, downstream demand is expected to increase.

Adipic-Acid – Plastic – Automotive