Automotive RPET Viscosity Modifiers 06-11-2021 - Arhive

Automotive RPET Viscosity Modifiers

-European virgin PET rises above RPET as virgin PET prices hit 10-year high

- Virgin PET resin Eur30/mt over RPET

- Spot supply expected to remain tight

Northwestern European prices of virgin polyethylene terephthalate moved to premium over recycled PET clear flakes on Nov. 3 for the first time since June 8, as PET prices hit a 10-year high, S&P Global Platts data showed.

Virgin PET values have been on a rally since mid-August amid an acute material shortage in Europe, coupled with increasing demand from PET resin consumers, who are looking to secure volumes.

S&P Global Platts last assessed PET FD NWE at Eur1,500/mt on Nov. 3, up Eur100/mt from Oct. 27, the highest since April 20, 2011, and at a Eur30/mt premium over Platts Recycled PET clear flake FD NWE assessment.

R-PET clear flakes were assessed at Eur1,470/mt FD NWE, up Eur20/mt from Oct. 27.

Spot availability of PET remains extremely tight, as European producers face a lack of feedstock PTA, which prevents them from operating at full capacity. High freight rates and logistic delays have made it difficult for Europe to import enough PTA and PET from Asia.

Most PET producers were heard already sold out for November, according to sources, with the availability for December deliveries already looking limited.

“It is not possible to get [PET] resin. If you have a contract with some agreed volumes, you can expect to get the lowest [end of] agreed volumes,” a converter said.

Demand for PET resin continues to outpace supply and some buyers are hunting to secure any volumes they can.

“Some customers are extremely desperate. Material remains scarce,” a trader said.

The supply-side constraints are unlikely to ease anytime soon. A trader said that looking ahead, the market is already tighter for January and February delivery periods.

RPET Conversion costs jump

Bottle bale-to-flake converters have not only been impacted by higher virgin PET resin prices but higher costs of production due partly to the escalation of energy costs.

Aside from a surge in recycling costs, the real concern for converters was not only a rise in material costs but also any potential for panic buying which could see shortages return going forward.

Innovative sensor-based sorting solutions from TOMRA Recycling have been installed at Mid UK Recycling’s new £15m state-of-the-art Lincolnshire-based material recycling facility (MRF) which became operational in June 2021.

Mid UK’s multi-million-pound Barkston MRF, near Grantham, processes 30 tonnes per hour (tph) of dry mixed recyclables from domestic and commercial recycling collections. As part of the MRF’s development, 14 of the latest generation TOMRA AUTOSORT® units have been installed across two lines to enhance the sorting process, boosting throughput and elevating purity levels of the targeted end fractions.

TOMRA’s new equipment at the Barkston MRF focuses on sorting a variety of fractions, including paper, film, magazines and a range of plastics, including high-density polyethylene (HDPE), polytrimethylene terephthalate (PTT) and polyethylene terephthalate (PET). Mid UK Recycling was already familiar with the capabilities of TOMRA’s AUTOSORT® technology as previous versions of the units were installed in Mid UK’s original MRF at the site.

TOMRA’s AUTOSORT® units can be easily programmed to separate different comingled recycling streams into specific materials ready to be sent on for further reprocessing or to end customers in both regional and international markets. At the new Barkston MRF, the technology is used in a two-step process to maximise the purity and market value of the recycled fractions and deal with challenges of sorting and extracting maximum value from mixed plastics.

New offering expands the options for advancing the plastics circular economy

Ghent, Belgium – Milliken & Company, a globally recognized leader in polymer additives and colorants, has launched DeltaFlow™ Viscosity Modifiers specifically to help polypropylene (PP) recyclers. Automotive RPET Viscosity Modifiers

Recyclers can use DeltaFlow, a solid concentrate, to increase the melt flow rate of recycled polypropylene (rPP) for the extrusion and injection molding processes. Milliken offers DeltaFlow in free-flowing pellets, which makes the product easy to feed, safe to handle and dust free.

DeltaFlow-optimized resins allow for lower processing temperatures, which can enable converters to reduce cycle times, boost productivity and improve processability.

Brand owners stand to benefit, as well. DeltaFlow enables recycled polypropylene to feasibly replace virgin resin in many end-use applications. This allows brands to use more rPP in their products, thereby helping them to meet their sustainability goals.

This new concentrate nicely complements Milliken’s existing family of DeltaMax® Performance Modifiers for polypropylene that enhances the physical properties and melt flow of rPP resins by allowing recyclers and converters to optimize their formulations and blends machine-side.

New Village Initiative Advanced Materials Group’s (NVIAMG) NewRoad™ asphalt additives engineered with waste plastic recently reached the five-year milestone of strong in-field performance in some of the nation’s harshest pavement-testing environments.

New Village Initiative Advanced Materials Group’s NewRoad™ hybrid polymer asphalt additives have performed well for five years on state, county and city roads and highways and commercial parking lots. Automotive RPET Viscosity Modifiers

“We have five years of use with strong results,” says NVIAMG President Mark Beeman. “No failures. No recalls. No tear-outs. No complaints.”

NewRoad™ contains highly engineered polymers made from post-consumer and post-commercial plastic. NewRoad™ adds as much as 50% to a road’s lifespan while helping keep plastics out of the environment.

Longer pavement lifespans mean a chance to lower carbon footprints and the potential to save money.

Standard Hamburg torture tests showed NewRoad™ pavement resists rutting and cracking far more than conventional mixes.

Even more impressive: The stellar performance in the field. The pavement has earned rave reviews even after withstanding the unforgiving, freeze-and-thaw weather of Iowa and Minnesota. NewRoad™ also performs well in extreme heat.

Beeman adds: “Five years of real world road and parking lot projects in harsh environments confirm that NewRoad™ exceeds customer and industry expectations.”

-Farsoon and Covestro strengthen cooperation in engineering powders

Materials manufacturer Covestro operates Farsoon Laser Sintering Systems in their German and Dutch (legacy-DSM) additive manufacturing facilities for testing the processing and printing of new materials such as thermoplastic polyurethane (TPU), polypropylene (PP) and polybutylene terephthalate (PBT).

Downstream customers have validated such parts for end-use applications in automotive, electrical and consumer industries.

Based on customer feedback and success, the two companies are strengthening their collaboration to foster series production of 3D-Printing.

Both Farsoon and Covestro are committed to an open systems philosophy so customers are free to choose materials for their 3D-printing systems that suit their end-use applications. Automotive RPET Viscosity Modifiers

In this collaboration, Covestro is contributing its expertise in polymer-based 3D printing materials and Farsoon its expertise from powder-based laser sintering machines.

Covestro has already successfully launched TPU and PBT polymer powders developed on Farsoon 252P-series machines. The development of additional powders and the upscaling to larger series applications is part of the strengthened collaboration.

Expanded opportunities in the 3D printing market

Covestro, Farsoon and Seifert Logistics Group (SLG) in Ulm, Germany jointly developed TPU parts for footwear. Seifert Logistics fabricates TPU parts on a Farsoon SS403P at high productivity levels.

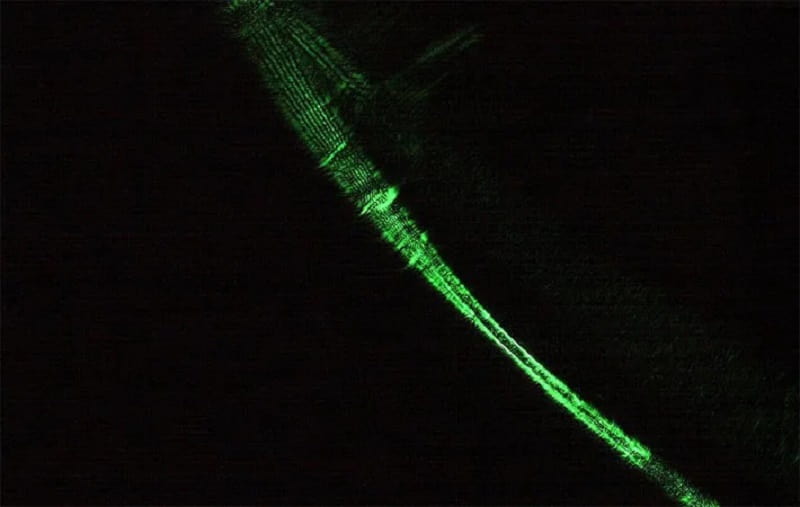

-Japanese universities are developing strong conductive fibers with bagworm silk

Researchers at the University of Tsukuba in Japan have developed strong conductive fibers using natural silk and synthetic conductive polymers of Minomushi, promising flexible electronic materials. A research team led by a professor at Hiromasa Goto used the strength of bagworm silk to produce durable and flexible conductive fibers.

This research has the potential to lead to new flexible electronic devices such as wearable electronic materials. Due to its high flexibility and strength, Spider Silk has received a great deal of attention in applications ranging from medical to aerospace applications.

By combining natural silk, such as spider silk, with synthetic conductive polymers, researchers can produce textiles with conductive, luminous, and photoelectromotive functions. The university said in a press release that it is also possible to create biocompatible materials that can be used in regenerative medicine and biomedical materials. Automotive RPET Viscosity Modifiers

“We have taken the next step from our research efforts by utilizing the most powerful known natural fiber, bagworm silk.” Professor Hiromasa Goto explained..

Researchers at the University of Tsukuba in Japan have developed strong conductive fibers using natural silk and synthetic conductive polymers of Minomushi, promising flexible electronic materials. A research team led by a professor at Hiromasa Goto used the strength of bagworm silk to produce durable and flexible conductive fibers.

“In this study, the research team combined polyaniline, an easily synthesizable conductive polymer, with bagworm silk from bagworm nests. The composite fibers from silk and polyaniline are 2 microns in diameter. It acted as an optical bagworm. Researchers have demonstrated that while green laser light propagates along these fibers, it remains confined within each fiber. To determine, researchers performed superconducting interference device (SQUID) measurements, which revealed that the composite fibers could function as paramagnets. When placed in an external magnetic field, the fibers were magnetized. By applying the bagworm silk / polyaniline composite material to electro-effect transistor devices, the research team also confirmed that the composite fiber is suitable for use in fiber transistors, “the release added.

-Adler Pelzer Group closes the acquisition of the Acoustics and Soft Trim business of Faurecia

Adler Pelzer Group (APG) announces to have closed the process of acquisition of Faurecia Acoustics and Soft Trims (AST), after all clearances by relevant merger control authorities have been received.

Faurecia AST is operating in Europe, with industrial activities mainly carried out in plants located in France (Marckolsheim, Mornac, Mouzon, Saint-Quentin), Luxembourg (Eselborn), the United Kingdom (Washington), Spain (Olmedo), Poland (Legnica) and a R&D centre in France (Mouzon) with approx. 1800 employees and 270M€ sales in 2020.

With this acquisition, APG makes a further step towards its vision of becoming a worldwide leader in automotive acoustics, as an industrial investor with long term loyalty to automotive and proven track record of growth.

The acquisition will bring value to the interior market thanks to complementarity of customers, industrial and operational footprint

– Improving intimacy to OEMs like Stellantis and Renault-Nissan alliance, thanks to the strong relationship capitalized by AST along years of cooperation and presence in France and UK;

– Complementing the above by a strong presence in East Europe, with know-how and footprint created by the strong foothold with German OEMs in Germany and East Europe, as well as with Stellantis in Italy and USA;

– Integrating in the APG worldwide R&D network an additional strong centre, the AST R&D centre of Mouzon, France. APG can this way dedicate a full matrix of Centre of Excellence by product family and local customer support;

– Benefiting from combined innovative programs on new products and CO2 reduction, as well as opportunities on material supply and vertical integration.

-Three ALPLA plants in Germany produce climate-neutral

Emission reduction in Exter, Lübeck and Föritztal and regional reforestation project

Hard, 4 November 2021 – Following the initial step of significantly reducing their CO2e emissions, ALPLA’s German plants in Exter, Lübeck and Föritztal have been made climate-neutral in accordance with Scopes 1 and 2 with the help of carbon certificates. A regional reforestation project is additionally being supported.

CO2e accounting was performed in early 2021 at the start of the project with the aim of significantly reducing the CO2e emissions of ALPLA’s German plants in Exter, Lübeck and Föritztal. The goal of reducing CO2e emissions as much as possible was then announced, and this was achieved in the first step by means of a conversion to green electricity. This significantly lowered emissions from a good 22,000 tonnes of CO2e in 2020 to just under 2,000 tonnes of CO2e (Scopes 1 and 2) in 2021. For comparison purposes, this saving equates to the CO2e emissions of a good 4,400 passenger vehicles run normally a year.

Regional reforestation project

In a second step, carbon certificates were purchased for the remaining 2,000 tonnes, to officially make the plants carbon-neutral in accordance with Scopes 1 and 2. With the focus being placed on regional offsetting, a further 500 tonnes of CO2e were voluntarily offset through a reforestation project. This additional effort is supporting the reforestation of damaged areas and preservation of the forest in Bösingfeld, which is around only 30 kilometres from the Exter plant.

Automotive RPET Viscosity Modifiers