Biodegradable-plastic – Plastic-recycling 15-02-2022 - Arhive

Biodegradable-plastic – Plastic-recycling

-With an annual output of 30,000 tons, the largest PBAT project in Southeast Asia has started!

Recently, the groundbreaking ceremony of the biodegradable plastic (PBAT) factory project under An Phat Holdings was held in Nam Dinh Vu Industrial Zone, Hoi An County, Hai Phong City, Vietnam.

The biodegradable plastic production plant is the first green raw material production plant in Southeast Asia. It is listed in the list of high-tech projects for priority investment, with an annual production capacity of 30,000 tons. It is expected to be completed in 24 months. Biodegradable-plastic – Plastic-recycling

The total investment of the project is 120 million US dollars. After it is put into operation, it will be able to meet the demand for raw materials of Anfa Holding Group and export it to the outside world. The project is expected to create employment opportunities for about 200 high-quality workers.

Fan Yingyang, chairman of Anfa Holding Group, said that the project will solve the group’s demand for raw materials, implement raw material autonomy, reduce costs, and deliver products to consumers, thereby replacing traditional plastic products. On the other hand, the group hopes to take the lead in developing this market in Vietnam as the green development trend continues to expand. The group strives to be the first to implement Vietnam’s commitment to net zero emissions by 2050.

The official start of the biodegradable plastic production plant is an important foundation for the Group to further expand and develop green products and raw material projects around the world. Anfa Holding Group strives to become a leading high-tech and environment-friendly plastics group in Southeast Asia, boosting the development of Vietnamese enterprises and enhancing the status of Vietnam’s high-tech and environment-friendly plastics brand. Biodegradable-plastic – Plastic-recycling

-Greece to pay about 127 million over poor plastic recycling record

Greece will have to pay around €127 million to the European Union this year due to its low performance in recycling plastic packaging.

The fine is aimed at increasing the recycling of plastics across the EU.

According to a study on the role of plastics in the circular economy of Greece, prepared by think tank IOBE on behalf of the Association of Hellenic Plastics Industries (SVPE), about 43,000 tons of plastic packaging is neither buried nor recycled each year. Biodegradable-plastic – Plastic-recycling

-BB Engineering GmbH Delivers Melt Filter For PET Recycling System To Indorama Polyester Industries

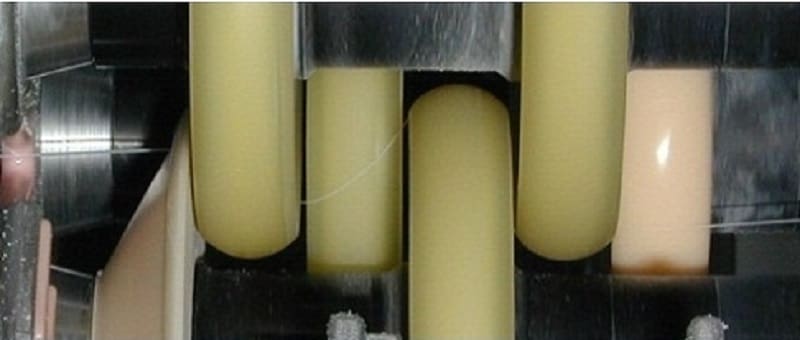

BB Engineering GmbH (Germany) delivered a melt filter for recycling PET flakes to polyester manufacturer Indorama Polyester Industries (Thailand). Indorama will be using the type NSF38 filter in its recently assembled recycling system in order to produce rPET granulate from flake PET bottle waste.

The NSF38 filter enables continual filtering – in other words, the system switches from one filter to the other during the process without the need for conversion shut-downs. Biodegradable-plastic – Plastic-recycling

The filter allows the processing of consumer waste – for example, in the form of shredded PET bottles – into new, high-quality rPET granulate. This granulate is subsequently processed into manmade fibers in spinning systems.

The NSF38 is a switchable filter with a filter surface area of ap- prox. 16 m2 on each side, with throughputs of between 1,000 and 1,900 kg/h. The filter inserts each contain 19 pleated filter candles (60 x 1,000mm Ø).

-PET bottle chip export order intake exceeds 400kt in Jan

Post-Spring Festival holiday, PET bottle chip price hiked 250-400yuan/mt. Spot discussion for near-term goods have risen to 8300-8500yuan/mt by cash EXW, and prevailing discussion for Apr-Aug goods was at 8235-8370yuan/mt. Mainstream export talks in E. China lifted to $1150-1195/mt FOB Shanghai, up $30-50/mt from pre-holiday level. Biodegradable-plastic – Plastic-recycling

In fact, PET bottle chip industry fundamentals are strong, coupled with low factory inventory and tight spot supply, which forms a pattern that is easy to rise and difficult to drop. After the holiday, as raw materials cost hiked, PET market price naturally moves higher. According to CCFGroup statistics, China PET bottle chip export order intake exceeded 400kt in Jan 2022, up nearly 60% from a year earlier, flat from Sep 2021 high. So far, most plants begin to sell Q2 orders. Though the newly online unit is offering materials in Jan, its impact is limited, as its monthly output may not reach 900kt. PET resin export share is expected to reach above 45% in Jan.

So far, it can be basically confirmed that the domestic export delivery volume of PET bottle chip will not be too small in Q1. It is estimated that the export volume will be around 350000 tons in January, 250000-300000 tons in February and slightly above 400000 tons in March. However, it mainly depends on the final arrangement of the shipping schedule. In terms of domestic sales, orders in the second quarter are still on the loose side. Biodegradable-plastic – Plastic-recycling

However, precisely because domestic and foreign sales orders have been taken in ahead of time, since the second quarter, if the pace of order intake slows down, PET bottle chip factories are expected to turnaround ahead of schedule. The specific time is not determined now, for example, it was originally scheduled in April, but in view of the tight delivery, it may also be postponed to the end of June. Therefore, it is expected that the total inventory will slip to around 1 million tons by the end of March, nearly 200000 tons lower than that at the end of last year, while it’s of small chance to accumulate in the second quarter, mainly depending on the maintenance plans by then.

-Polyester DTY machine growth rate change

Polyester DTY machine increased by around 2,000 tons in Chinese mainland in 2021, the biggest increment in history, and witnessed 10-year new high of growth rate at 9.9%. Biodegradable-plastic – Plastic-recycling

According to the growth rate of DTY machine in recent decade, capacity expansion peak appeared in 2017-2018 and 2021. In 2017-2018, new DTY machine peaked as apparently increasing fabric mills integrated with DTY production. In 2019-2020, small DTY plants were less competitive compared with big plants with falling prosperity. New DTY machine mainly came from PFY plants and some fabric mills. Few small DTY plants expanded capacity. As a result, the growth rate of DTY machine fell back. In 2021, the increment of DTY machine hit historic new high as small DTY plants showed high investment enthusiasm and PFY producers further increased DTY production amid good profit in the fourth quarter of 2020.

Comparing the increase of DTY machine and fabric manufacturing machine in recent 5 years, there are various types of fabric manufacturing machine, which is converted into the consumption of chemical fibers. Downstream capacity expanded intensively in 2017-2018. DTY machine and the consumption of chemical fibers among fabric manufacturing machine both extended higher. However, the profit of DTY and fabrics apparently declined in 2018 after new capacity rose. That meant falling growth rate in 2019 and the reduction of DTY machine was more apparent. In 2020 and 2021, the growth rate of chemical fiber consumption among fabric manufacturing machine was basically flat with that in 2019, while that of twisting machine gradually ascended, especially in 2021. Biodegradable-plastic – Plastic-recycling

The growth rate of DTY machine even outpaced that of chemical fiber consumption of fabric manufacturing machine mainly because DTY market witnessed obviously soaring profit since the fourth quarter of 2020.

-The next steps for recycled polystyrene

The value chain initiative, Styrenics Circular Solutions (SCS), has filed a second application for European Food Safety Authority (EFSA) approval of mechanically recycled polystyrene based on the Gneuss super-cleaning technology. What does this mean for the polystyrene value chain’s circularity bid?

Fraunhofer IVV has submitted a scientific dossier representing the SCS initiative’s second application for food contact authorisation for mechanically recycled polystyrene (rPS). While both submissions apparently cover the same end-consumer applications, including yogurt pots, beverage containers, and food trays, they are based on two different super-cleaning technologies as part of PET-like food contact recycling processes. Biodegradable-plastic – Plastic-recycling

The super-cleaning technology

The second application is based on the super-cleaning technology of the plastic recycling machine manufacturer, Gneuss, which the group says has undergone “several successful” challenge tests. The technology used is Gneuss’ Multi Rotation System (MRS) jump extrusion process that allegedly enables highly efficient super-cleaning based on high vacuum, high surface, and melt temperatures.

The initial mechanical recycling process –– where PS is sorted into bales and then ground into flakes, which are subsequently hot washed –– reportedly produces PS with a purity of 96%. Near infrared and high-speed camera technology are used as part of the final sorting process to remove any remaining non-rigid or non-white PS flakes.

This is the point at which the flakes enter the super-cleaning stage. Melted at temperatures of around 240oC, the surface area of the polymer is then enlarged to enhance exposure to the vacuum technology that further removes any remaining impurities before pelletisation. Overall, the group claims that the super-cleaning process produces PS with a purity of over 99%. Biodegradable-plastic – Plastic-recycling

The initiative claims that, in a standard extrusion machine used to produce PS sheets, the mechanically recycled and super-cleaned PS performs “identically” to virgin PS with unchanged processing parameters and surface quality.

Biodegradable-plastic – Plastic-recycling