Biosuccinium – Gas-crisis – rPET 07-09-2022 - Arhive

Biosuccinium – Gas-crisis – rPET

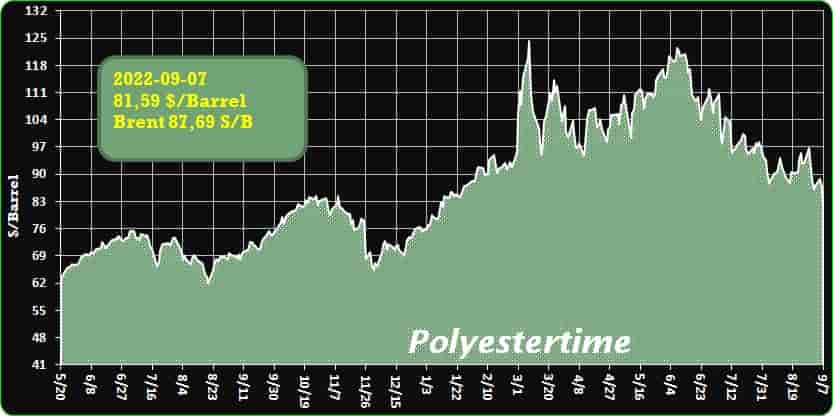

Crude Oil Prices Trend

-Gas crisis: Moscow is not winning and the war will not block green energy, three false truths to be dismantled

You could have more energy, and cleaner, and avoid writing checks after checks, making yourself a little less dependent on Russia. This is happening in Europe, one step away from the worst gas crisis since the postwar period. And as the gas crisis continues to affect households, businesses and entire economies around the world, it’s important to separate facts from false truths. Fatih Birol, executive director of the International Energy Agency, entrusted the Financial Times with a speech in which he makes three key points clear: “There are three narratives in particular on the current situation that I believe to be wrong and in some cases dangerous: the first is that Moscow is winning the energy battle. The second is that the current global energy crisis is a clean energy crisis. The third is that the current emergency is disrupting the fight against climate change “.

In reality, Birol points out in his intervention in the Financial Times, today’s crisis can help accelerate the transition to a cleaner and safer energy future. Certainly difficult challenges await us starting this fall. But that doesn’t mean that Russia is winning or that efforts to tackle climate change are doomed forever. Biosuccinium – Gas-crisis – rPET

Gas crisis: Moscow is not winning

On the first point, Fatih Birol’s analysis in the Financial Times on the current gas crisis is without appeal for Moscow. The invasion of Ukraine – he writes – whatever the final result, will be a lost war for Moscow, which has proved to be an unreliable partner, cutting off supplies to the EU under the most diverse pretexts. Russia is undoubtedly a major supplier of energy and the increase in oil and gas prices triggered by the conflict has led, for now, to an increase in its energy revenues. But the short-term gain will be more than offset by the loss of confidence and markets it will face in the future. While, by accelerating energy diversification, Europe can escape any present and future energy blackmail. In the long term, regardless of the outcome on the ground, Moscow will have lost its main customer and strategic partner.

And we come to the crux of the sanctions. To those who argue that they do not produce effects, Birol replies that by doing so, the medium-term impacts on the Russian oil and gas sector are not considered. This particularly concerns its ability to produce oil and transport gas. An increasing share of Russian oil production was destined to come from more complex fields, including offshore, arctic or otherwise difficult to recover. “The absence of Western companies, technologies and service providers due to sanctions – writes Fatih Birol on Financial Times – involves substantial risks for the country’s ability to exploit these resources ”.

Furthermore, the Kremlin focused on liquefied natural gas as the main tool to diversify its exports, moving away from its strong dependence on Europe. “Before the invasion of Ukraine, Russia’s stated goal was to export 120-140 million tons of LNG per year by 2035, at least four times the current level. This now appears to be a distant prospect without partners and above all international technologies. The expansion plans of the Russian LNG are now at stake ”.

-Moscow, ‘Italy pushed to economic suicide by the US’

“Rome is driven to economic suicide by the Euro-Atlantic sanctioning frenzy”, and the result will be that Italian companies will be “destroyed by the ‘brothers’ from overseas”, since American companies today “pay seven times less for electricity than the Italian ones “. This was stated in a post on Telegram by the spokeswoman of the Russian Foreign Ministry Maria Zakharova.

“Sanctions have become an instrument of unfair competition” against Italian producers, adds Zakharova, according to which “when Italian companies collapse, they will be bought cheaply by the Yankees”.

-Technip Energies Buys DSM’s Biosuccinium Technology

French engineering and technology company Technip Energies has boosted its sustainable chemicals portfolio with the purchase of DSM’s biosuccinium technology. Financial terms were not disclosed.

Technip said it will be the only technology licensed on the market for producing bio-based succinic acid, which is a feedstock for manufacturing polybutylene succinate (PBS), a sustainable packaging material for food contact applications.

“This addition to our growing sustainable chemicals portfolio will allow Technip Energies to license a solution for the production of a bio-sourced and biodegradable polymer, which has a 50% lower carbon footprint compared to fossil-based routes,” said Bhaskar Patel, senior vice president, sustainable fuels, chemicals and circularity at Technip Energies. “Superior product properties, combined with best-in-class sustainability performance, are key attributes in today’s consumer market. Biosuccinium – Gas-crisis – rPET

We shall leverage the whole PBS value chain, where we already license the technology for the polymerization of the bio-sourced monomers into PBS.”

-Company takeover in Eastern Europe: Greiner Packaging buys Serbian PET flake producer ALWAG

In acquiring a Serbia-based producer of PET flakes, Greiner Packaging is broadening its portfolio of businesses and adding the first recycling company to the group. The purchase of ALWAG, which will be renamed Greiner Recycling d.o.o., sees Greiner expand its business model by additionally entering the business of reprocessing recyclable materials.

The acquisition of ALWAG is a direct reflection of Greiner Packaging’s exhaustive efforts to boost sustainability. In purchasing the PET flake producer, Greiner Packaging is pushing ahead with the expansion drive it has embarked on in recent years as well as resolutely pursuing its extensive circular economy goals. The ALWAG takeover means Greiner Packaging now has three locations in Serbia: one recycling company and two manufacturing bases. Biosuccinium – Gas-crisis – rPET

Recycling: an integral part of the business model One of Greiner Packaging’s declared objectives is to maximize the use of recycled material when manufacturing its products. As the first recycling company in the group, Greiner Recycling d.o.o. will help to secure the material streams that will later be converted by Greiner Packaging. This sustainable form of backward integration will ensure a dependable supply of raw materials that are essential to Greiner Packaging continuing to offer customers the reliability they are accustomed to going forward. It is also key to expanding recycling as an integral part of the company’s business model.

“PET is currently the only mechanically recycled material that can be used for food applications. We are strong believers in the potential of PET and, by expanding our expertise, we are actively committed to using this material effectively. As we work toward our sustainability goals, which we pursue consistently through all the business decisions we make, we naturally pay special attention to the possible creation of other r-PET streams in addition to the bottle-to-bottle stream. That would mean that an old PET cup could become a new PET cup in the future,” explains a confident Manfred Stanek, CEO of Greiner Packaging.

Use of PET flakes ALWAG currently supplies its material to customers throughout Europe. Following consultations with these valued partners and a planned expansion of recycling capacity at the site, the flakes will gradually become available for Greiner Packaging’s applications and will be incorporated into its packaging solutions. This means that existing ALWAG customers will continue to benefit from a reliable supply of their usual quantities of recycled material. To incorporate recycled PET into packaging, the PET flakes are extruded and then thermoformed. In the future, injection molding applications will also be considered.Biosuccinium – Gas-crisis – rPET

“The recycling of PET packaging and bottles is a project we began 10 years ago as pioneers in Serbia. It has always been our ultimate goal to produce an end product made entirely of recycled PET material that can then be converted. This new ALWAG product is now no longer being developed by us, but by new owners whom we have carefully selected and have full confidence in. We are convinced that our vision will be successfully pursued thanks to the new owners, their commitment to the Nova Gajdobra site, and the additional investments in downstream technological processes. This step makes sense for everyone involved and will take the company’s success to even greater heights in the future,” comments Stojan Dangubić, former director of ALWAG and executive director of Aling-Conel.

-Eni eyeing Egypt as a gas supplier to Europe

The Egyptian President Abdel Fattah El-Sisi met with the Italian oil and gas company Eni’s CEO Claudio Descalzi on 30/8/2022 to follow up on Eni’s activities in the country and the areas of common interest and collaboration, said the company.

The two sides had extensive discussions about further boosting natural gas flows to Europe from several Egyptian assets.

Tactical Report has prepared a 254-word report to shed more light on El-Sisi- Descalzi meeting and Eni’s plan in Egypt.

The parties elaborated on Egypt’s vision of becoming a regional gas hub, leveraging existing LNG plants. Eni currently produces about 60% of total gas in the country. The company is committed to supporting gas production increase through an ambitious exploration and development campaign.Biosuccinium – Gas-crisis – rPET

This will foster, through the Damietta liquefaction plant, LNG export toward Europe. Eni has recently been awarded from the last bid round five new licenses located in prolific basins that could enable a fast-track development leveraging the nearby existing facilities.

In the light of energy transition, the parties agreed on the opportunity to implement a set of solar and wind power projects, targeting 10 GW of installed capacity in the forthcoming years. Mr Descalzi elaborated also on the strategy to accelerate the decarbonisation and energy efficiency solutions.

Eni has been present in Egypt since 1954, where it operates through the subsidiary IEOC. The company is currently the country’s leading producer with an equity production of hydrocarbons of approximately 350,000 barrels of oil equivalent per day.

-UBQ Materials earns European UL 2809 recycled content validation

Technology firm UBQ Materials has received the UL Environmental Claim Validation (UL2809) mark, which confirms that UBQ – a novel thermoplastic made from unsorted municipal solid waste, contains 100% post-consumer recycled content

.The certification confirms that companies and manufacturers can substitute oil-based resins with UBQ to maximize post-consumer recycled content in products.

European plastics industry groups have aligned themselves with the policy proposal from the European Commission to meet mandatory minimum of 30% recycled content in plastic packaging by 2030. Biosuccinium – Gas-crisis – rPET

UBQ Materials is already working with Mercedes-Benz, PepsiCo, and McDonald’s, to reduce the carbon footprint of their end products, maximize recycled content.

Albert Douer, chairman and co-chief executive of UBQ Materials, said: “In light of regulations and taxations, global corporations are running against the clock to assess and implement solutions to fulfill ambitious ESG commitments. There is an urgent and growing demand for quality post-consumer recycled content materials that support these goals.

-RGE is developing closed-loop textile-to-textile recycling solutions

Singapore-based viscose giant Royal Golden Eagle (RGE) is creating what it says are the first-of-their-kind closed-loop textile-to-textile recycling solutions, to speed up innovation in textile recycling that CAN be used in urban environments.

Through the recently established RGE-NTU Sustainable Textile Research Center, RGE is creating the solutions (RGE-NTU SusTex). RGE and Nanyang Technological University in Singapore are working together on this research project for five years (NTU). The research center will generate new eco-friendly and sustainable textiles by developing innovative ways to convert textile waste into fiber.

The goal is to overcome the inadequacies of present textile recycling methods, which are unsuited for urban settings owing to the usage of heavy chemicals, and handle the “immense” textile waste created in urban areas as a result of waste material import prohibitions.Biosuccinium – Gas-crisis – rPET

According to Perry Lim, executive director of RGE, said that environmental regulations prevent the use of current textile recycling methods, which rely largely on a bleaching and separation process utilizing heavy chemicals. The pressing need to keep textiles out of the overflowing landfills is there at the same time. They strive to accelerate closed-loop, textile-to-textile recycling as the largest manufacturer of viscose in the world by creating the best urban-fit solutions that can move society closer to a circular textile economy.

The majority of the textile recycling methods now in use, according to RGE, are open-loop systems in which textile waste is generally downcycled into lower-quality products (insulating materials, cleaning cloths, etc.) or utilized in waste-to-heat recycling.

Lim adds that the development of closed-loop chemical recycling techniques for textiles, in particular, is ongoing. The technologies still need to be scaled up to an industrial level. The requirement for feedstock purity criteria for recycling textile waste into fiber is a major barrier. However, the majority of the clothing we wear is a complicated blend of synthetic and natural fibers, making it difficult to separate the ingredients for efficient recycling. Their goal is to find practical solutions that can be scaled up throughout their worldwide operations and that utilize less energy, fewer chemicals, and create less harmful effluents in order to address this industry’s pain point. Biosuccinium – Gas-crisis – rPET

-Making Home Charging Stations Safer with Flame-Retardant PA

Cable connectors made of halogen-free, flame-retardant polyamide (PA) 6 from Lanxess features enhanced tracking resistance, processability.

In addition to their use in battery and electric powertrain applications, engineering plastics also have great application potential in the charging infrastructure for electric vehicles. This particularly applies to wall-mounted charging stations.

Wallboxes must be very safe because they are used inside buildings such as parking structures or private garages. The material selection criteria are correspondingly strict.

One plastic that meets these high requirements is the halogen-free, flame-retardant Durethan BKV20FN01 from Lanxess.Biosuccinium – Gas-crisis – rPET

The polyamide (PA) 6 compound is used to make charging cable connectors manufactured by Leopold Kostal GmbH & Co. KG, a global supplier of automotive, industrial, and solar electrics as well as electrical contact systems. The charging cable connectors are used in Kostal’s Enector wallboxes, which are distributed via Kostal Solar Electric, as well as in wallboxes from a leading German producer of industrial connector systems and charging solutions for electromobility.

In addition to their use in battery and electric powertrain applications, engineering plastics also have great application potential in the charging infrastructure for electric vehicles. This particularly applies to wall-mounted charging stations.

Wallboxes must be very safe because they are used inside buildings such as parking structures or private garages. The material selection criteria are correspondingly strict.

One plastic that meets these high requirements is the halogen-free, flame-retardant Durethan BKV20FN01 from Lanxess. The polyamide (PA) 6 compound is used to make charging cable connectors manufactured by Leopold Kostal GmbH & Co. KG, a global supplier of automotive, industrial, and solar electrics as well as electrical contact systems. The charging cable connectors are used in Kostal’s Enector wallboxes, which are distributed via Kostal Solar Electric, as well as in wallboxes from a leading German producer of industrial connector systems and charging solutions for electromobility.

High glow-wire resistance Biosuccinium – Gas-crisis – rPET

“The key arguments for using our material in this application are its high tracking resistance and flame-retardance based on the halogen-free flame retardant package.

It is also easy to process and produces components with a high surface quality,” explains Bernhard Helbich, Technical Marketing Manager, Key Accounts, at Lanxess.

The PA compound meets the UL V-0 rating at a test specimen thickness of 0.75 mm.

-China Sinopec lowers hydrogen development target for 2025

Chinese refiner Sinopec Corp is aiming to build 120,000 tonnes of annual hydrogen filling capacity for 2025, it said on Friday, 40% below the goal set a year ago.

The hydrogen capacity targets mostly the transportation sector as the state oil and gas major builds hydrogen filling stations alongside its vast network of petrol stations.

Sinopec said in a news release that it would expand making hydrogen via electrolysis powered by renewable sources in addition to the more traditional refining and chemical processes. Biosuccinium – Gas-crisis – rPET

It did not give a reason for the target revision but said it will “proactively and orderly” expand its hydrogen business.

Early this week a top company executive said the firm had by the end of June built 83 hydrogen filling stations and another 13 were under construction, making it the world’s largest among oil companies.

-Vietnam boosts foreign investment attraction in country’s automotive industry

Vietnam will move to attract large enterprises and corporations with high technology, said Nguyen Anh Tuan, deputy director of the Ministry of Planning and Investment’s Foreign Investment Agency.

At the same time, the country will prioritise investment projects in high technology, supporting industry, and digital economy innovation, especially in the automotive industry and to create favourable conditions for Vietnamese enterprises to participate in the value chain, according to Vietnam news agency (VNA).

Nguyen Thi Thu Ha, general director of Invest Global, said that with a population of nearly 100 million people and favourable natural and geographical conditions, Vietnam had great potential in the automobile industry.Biosuccinium – Gas-crisis – rPET

She added that this was also an industry that the Vietnamese government prioritised developing, with the expectation of building a strong Vietnamese auto industry and making important contribution to the economy.

It reported that however, compared with other countries in the region, the number of Vietnamese suppliers in the auto industry was still very small, and only a few domestic suppliers could participate in the supply chain for automobile manufacturers and assemblers in Vietnam.

Dang Hoang Mai, a representative of the Vietnam Institute of Strategy and Policy for Industry and Trade, said that Vietnam has the potential to develop the electric vehicle (EV) market in the future because the current car ownership rate of Vietnam was at 23 cars per 1,000 people. This figure was only equal to 10 per cent of Thailand and 5 per cent of Malaysia.

With increasing income levels and improved infrastructure, sales and output of the auto industry are forecasted to grow in 2021-2030.

However, contrary to the trend of rising car consumption, enterprises operating in the auto industry, especially the auto manufacturing supporting industry, did not grow as expected, said Mai.

The localisation rate for personal cars with up to nine seats is low at less than 20 per cent of which Thaco reaches 15 to 18 per cent. Toyota Vietnam is the highest at 37 per cent (for Innova models). Biosuccinium – Gas-crisis – rPET

Biosuccinium – Gas-crisis – rPET