Circular Economy PET Bottle 23-07-2021 - Arhive

Circular Economy PET Bottle

Crude Oil Prices Trend

-China PET bottle chip market outlook not as bad as expected after cutting down massive output ?

Recently, PET bottle chip factories begin to announce output cut plans, and operating rate of many plants has declined. So far, output of China Resources, Wankai, Indorama Guangdong, Dragon Special Resin, Sinopec and Baosheng has declined in varying degrees, involving a total capacity of about 1.64 million tons (excluding long-term shut Chengxing line). If add the 1.2 million tons long term shut line, the total capacity involved reaches 2.84 million tons. Average operating rate of China PET bottle chip plants has dropped to slightly below 75%. (82.8% based on designed capacity of 12.46 million tons)

In fact, this round of intensive output cutback and shutdown comes from two factors: first, the processing range of PET bottle chips has been compressed within 600yuan/mt for a long time, resulting in reduced profit space; second, new order intake both in and abroad are not good. The continuously rising sea freight due to tight supply of containers and delay of shipping dates makes it even more difficult for PET bottle chip factories.

First of all, the compression of the processing spread is caused by two sides, factories promotion and the rising raw materials cost. On the one hand, PET bottle chip industry is now highly concentrated, capacity of TOP4 PET bottle chip factories occupies more than 70% of the total. If one of the factories reduces production, the market share is bound to be divided by other factories. Recently, selling price of one large PET bottle chip manufacturer is relatively low, as its processing spread is basically reduced to around 500yuan/mt. This way, many other bottle chip factories with poor cost advantage are difficult to get new order.

-McDermott selected for licensed modular unit for largest PE integration project

McDermott International, Ltd announced it has been awarded an engineering and procurement contract for a spent caustic treatment solution on the Gas Chemical Complex (GCC) project from Heat Transfer Technologies DMCC (HTT), as per the company’s press release. Circular Economy PET Bottle

The GCC project is owned by Baltic Chemical Plant LLC, a subsidiary of RusGazDobycha. It is the largest polyethylene (PE) integration project in the world and is located near Russia’s shores in the Gulf of Finland.

“This award is a testament to our ability to leverage our suite of capabilities to provide integrated solutions throughout the lifecycle of a project,” said Tareq Kawash, Senior Vice President, Europe, Middle East, Africa. “Our proven experience delivering world-class polyethylene projects make us the ideal partner to continue supporting the GCC project.”

McDermott’s scope includes license technology rights, basic design engineering package (BDEP), module detailed engineering design and full procurement of main equipment. The modularized solution for the spent caustic treatment solution will be an integral part of the GCC project and enable the project’s annual production of up to 3 million tons of PE.

As MRC informed previously, McDermott International, Ltd has been also selected by LACC, LLC, a joint venture between Westlake Chemical Corporation and Lotte Chemical Corporation, to provide engineering, procurement and construction for a seventh heater addition to its LACC Ethane Cracker Facility in Westlake, La, USA. Schematic image for seventh heater addition to LACC Ethane Cracker Facility in Westlake, La.

-Ravago Acquires Equity Interest in Leading Advanced Recycling Company Alterra Energy

Ravago and Alterra Energy to Vertically Integrate to Supply Waste Plastic, Liquefaction Technology and Recycled Polymer Solutions Globally

Alterra Energy, an innovative advanced recycling technology company, and Ravago, a global leader in polymer recycling and distribution, announced today that Ravago has acquired an equity interest in Alterra Energy. Circular Economy PET Bottle

Ravago will be a strategic partner in supplying pre-processed waste plastic to Alterra Energy’s Akron, Ohio, facility — which currently has the capacity to liquefy up to 60 tons per day of waste plastic for use as a feedstock for the manufacturing of plastics and chemicals — as well as for future commercial installations.

Alterra Energy and Ravago plan to combine forces to provide integrated recycling solutions that support the transition toward decarbonization, decreasing virgin fossil resource dependency and increasing circularity for its petrochemical and chemical partners.

Sulzer Chemtech has announced a strategic partnership with Wageningen Food & Biobased Research. The global process technology specialist and research institute are combining their capabilities to develop new methods to produce competitive bio-based foamed polymers. These will provide material properties equivalent to their fossil-based counterparts while featuring extremely low environmental footprints.

Polymer foams have been in the market for more than 80 years and play a central role in products used in our everyday lives, from sofas and beds to food packaging for takeaways. Their light weight and good thermal insulation properties can support a broad range of applications. Nevertheless, their limited recyclability and sustainability are significant challenges that companies and research institutes need to overcome to support a circular economy of plastic. Circular Economy PET Bottle

Foaming process and foaming technology to market

With a focus on the development of scalable processing methods for bio-based foamed materials, the partnership between Sulzer Chemtech and Wageningen Food & Biobased Research aims to increase the market share of cost-competitive bio-based polymers in different sectors. The development of key manufacturing processes and technologies will help Sulzer Chemtech’s customers and end users benefit from solutions that anticipate the needs of tomorrow.

-KABRA Extrusiontechnik has developed economical tubular film blowing lines

KABRA Extrusiontechnik has developed economical tubular film blowing lines, said the company. Circular Economy PET Bottle

In Russia, the Kabra Extrusiontechnik company is officially represented by the Scientific Company (St. Petersburg), whose engineers will help to select the equipment and recommend a technical solution to the buyer exactly his task.

KABRA Extrusiontechnik (KET, India) is one of the largest manufacturers of extrusion equipment for the production of plastic pipes and films from polyvinyl chloride (PVC), polypropylene (PP) and polyethylene (PE) with more than 50 years of experience. Possessing high engineering qualifications and relying on the wishes of customers, the company successfully develops new technical and technological solutions.

One of the latest developments of the company is a cluster blowing line for the production of a single layer film, which consists of several extruders, blowing systems and from 2 to 10 winders combined into a single mechanism, fully synchronized and controlled from a single control panel.

It is noted that due to such a layout, it became possible to significantly save space for the location of production, make management easier and cheaper, and also produce a larger amount of finished products in a minimum time.

-India’s BPCL plans ethanol plant in Telangana state

India’s Bharat Petroleum Corp Ltd (BPCL) plans to set up an ethanol plant at a cost of Indian Rupees (Rs) 10bn ($134m) in south eastern Telangana state, a state government official said on Wednesday. Circular Economy PET Bottle

The proposed plant will have a capacity of 500,000 litres/day and will use grain as feedstock, the Telangana state government official said.

BPCL has not finalized the location of the ethanol plant as the state government is yet to allocate the land required for the company.

“BPCL has decided to set up this plant in Telangana as the state is currently ethanol deficient and would need a large ethanol plant to meet the government’s blending targets for fuel,” he said.

Once operational, the BPCL plant would help Telangana achieve India’s target of blending 20% ethanol in auto fuel by 2025.

The company is currently in the process of setting up three second generation (2G) ethanol plants with a capacity of 100 kilolitres/day in the three states of Odisha, Maharashtra and Madhya Pradesh as per the BPCL website.

Founded in 1992, EREMA North America (ENA), based in Ipswich, MA, distributes recycling systems from the Austrian machine manufacturer in North America and offers equipment trials at the customer center, on-site service, machine components and technical support. In December 2020, the 1,000th machine for ENA was shipped to South Carolina, from EREMA headquarters in Austria. It is now in operation at the facility of recycling service provider PreZero to recycle post consumer plastic waste.

PreZero US is a subsidiary of PreZero International and started operation in the USA in 2018 following the acquisition of a recycling services provider. Headquartered in Los Angeles, the company collects and processes washed LDPE and LLDPE film, containers and lids on the east and west coasts of the US.

The recycling facilities in Southern California and South Carolina process these post consumer material streams to produce high quality resins (LDPE, LLDPE, HDPE and PE), which is used as a substitute for virgin material in many applications. “This way we prevent this waste material from ending up in landfills. With our recycling facilities on both the east and west coasts, we can significantly shorten transport distances, which in turn also reduces CO2 emissions,” says Hendrik Dullinger, Vice President of Business Development.Circular Economy PET Bottle

Europe Textile Chemicals Market for Technical Textiles: Highlights

The Europe textile chemicals Market for technical textiles is projected to grow at a CAGR of more than2%between 2019 and 2027. Growing demand for hometech will drive the textile chemicals market in Europe. Further, rising demand for mobiltech and clothtech chemicals will propel the market during the forecast horizon. However, growing environmental concerns regarding the usage of textile chemicals will restrain the overall market. Some textile chemicals are also known to be carcinogenic. This has led to the emergence of biobased alternatives that will hinder the growth of the market. Circular Economy PET Bottle

Technical textiles are manufactured for technical and functional purposes rather than decorative and esthetic purposes. They are primarily manufactured from synthetic fibers. They are employed in several end-user industries such as automotive, sports equipment, agriculture, and health care.

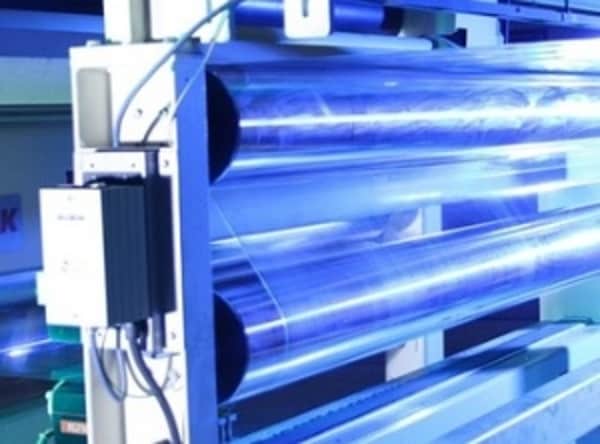

-India’s SRF commissions 45,000 tonne/year BOPP unit in Thailand

India’s SRF Ltd has commissioned its new 45,000 tonne/year biaxially oriented polypropylene (BOPP) unit in Thailand.

The new plant is located at the company’s manufacturing site in Rayong province, the company said in a statement on 20 July.

There is a strong market in Thailand for BOPP films as the country is currently a net importer of the material, the company said. Circular Economy PET Bottle

Currently, SRF operates two biaxially oriented polyethylene terephthalate (BOPET) lines – a 30,000 tonne/year unit and a 40,000 tonnes/year unit – at the Rayong complex.

Economical synthesis of polyacrylates and polymethacrylates from biobased materials

Despite the best efforts of industry to work towards sustainability, most plastics (or polymers) are still made using non-renewable fossil fuels. However, researchers have now found an economical method for producing biobased acrylate resins. The study, published in the journal Angewandte Chemie, shows how all the synthesis steps, from initial building blocks right up to polymerization, can be carried out in a single reactor (one pot), minimizing environmental impact.

Most varnishes, adhesives and paints are made from acrylate resins, which are polymers of acrylic acid esters and methacrylic acid esters. The raw materials that form these esters are acrylic or methacrylic acid, and alcohols. The alcohols give the plastics properties, such as softness or hardness, and water absorption or repulsion.

To make these polyacrylates and polymethacrylates more sustainable, Christophe Thomas and his team from the Institut de Recherche de Chimie in Paris, France, used alcohols from biobased or natural sources, rather than fossil sources. These included plant-based lauryl alcohol, menthol, tetrahydrogeraniol (a pheromone-like substance), vanillin, and ethyl lactate. Circular Economy PET Bottle

Circular Economy PET Bottle