BlowMoulding Circulareconomy BioFiber 22-07-2021 - Arhive

BlowMoulding Circulareconomy BioFiber

Crude Oil Prices Trend

-Safe in PET: COVAP’s first complete aseptic PET line from Sidel

Thanks to Sidel’s end-to-end complete aseptic PET line, UHT liquid dairy products (LDPs) from Spanish milk producer COVAP are now also available in PET bottles for the very first time. This new PET bottle opens the door to meet changing market demand and ensures product integrity and safety.

COVAP, a Spanish cooperative, is one of the major milk producers in Spain. The company has one of the most technically advanced dairy plants in the whole of Europe and has been a family of farmers for over 60 years. With a large operating area of 22,650 m2, COVAP can produce 400 million liters of milk per year. Traceability is their key to sustaining high-quality products. By implementing strict control from animal feed to the production process, they are able to keep their commitment of bringing a range of high-quality LDPs to consumers.

COVAP also produces ready-to-drink dairy products for other retailer brands in Spain.

New closed-loop technology will provide cost-effective solution to create new sustainable materials from automotive plastic waste

Eastman (NYSE: EMN) today announced a collaboration with the United States Automotive Materials Partnership LLC (USAMP) and automotive recycler PADNOS for a concept feasibility study to demonstrate a closed-loop project to recycle automotive-industry mixed plastic waste in the automotive supply chain. USAMP is a subsidiary of the United States Council for Automotive Research LLC (USCAR).

When automobiles are at the end of their life, metals, tires, and glass account for 80%–90% of the materials that can be recycled through traditional mechanical recycling streams. The other 10%–20%, referred to as automotive shedder residue (ASR), consists of mixed plastic and other non-recycled materials that currently end up in landfills or are recovered through waste-to-energy technologies. Under this initiative PADNOS will use ASR as a sustainable feedstock for Eastman’s molecular recycling process, creating a truly circular solution. BlowMoulding Circulareconomy BioFiber

-Carbon fibre manufacturing in Vietnam / Initial focus on goods for sports and outdoor activities

Teijin Carbon Vietnam (TCV), part of Japan’s Teijin (Tokyo; www.teijin.com) has started manufacturing carbon fibre products, including prepeg – a fibre sheet pre-impregnated with matrix resin as an intermediate material for composites. The Vietnamese business was set up on 4 May 2019 to capitalise on the expanding demand for carbon fibre, while also strengthening Teijin’s global business capabilities.

Initially, TCV will produce carbon fibre materials for sports and outdoor activities, including fishing, golf, bicycle and ice hockey goods for markets in South and Southeast Asia as well as Asia-Pacific. Demand is growing in the region, partly boosted by the Covid-19 pandemic, which has stimulated interest in activities that are compatible with social-distancing protocols. BlowMoulding Circulareconomy BioFiber

-Blow Moulding Technologies Deploy Simulation on 3DEXPERIENCE Cloud with TECHNIA

TECHNIA, the #1 knowledge leaders in PLM and Engineering, announced today a new agreement in their strategic partnership with Blow Moulding Technologies (BMT) – a manufacturer of, and service provider for, injection stretch blow moulding machinery.

BMT is a technology spin-out company from Queen’s University, Belfast, Northern Ireland, founded in September 2011. Their vision is to provide a scientific approach to stretch blow moulding. Through advanced software and hardware solutions, they aim to reduce energy consumption, optimise setup, and increase productivity.

BMT aims to expand their current Computer Aided Engineering (CAE) capabilities and deliver an automated Finite Element Analysis (FEA) optimisation workflow to satisfy their expanding project requirements by employing the 3DEXPERIENCE platform, provided by TECHNIA. BlowMoulding Circulareconomy BioFiber

Following a series of tests and discussions, TECHNIA were able to recommend a simulation solution within the 3DEXPERIENCE platform which satisfied BMT’s workflow requirements, whilst also using the latest simulation technology on the cloud.

Strengthens Trinseo’s strong position in acrylic solutions and drives expansion into wellness, niche leisure and architectural end markets in key geographies, including Asia

Purchase price of $445 million; implied purchase multiple of 7.0x enterprise value / 2021 estimated Adjusted EBITDA including $50 million tax benefit from basis step-up and $10 million annual run-rate cost synergies BlowMoulding Circulareconomy BioFiber

Transaction is expected to be growth, margin and cash flow accretive

Trinseo a global materials company and manufacturer of plastics, latex binders and synthetic rubber, today announced its entry into an agreement with SK AA Holdings, LLC, an affiliate of Falcon Private Holdings, LLC (“Falcon”), to acquire Aristech Surfaces LLC (“Aristech”), a leading North America manufacturer and global provider of polymethyl methacrylates (PMMA) continuous cast and solid surface sheets, serving the wellness, architectural, transportation and industrial markets.

-BHS-Sonthofen introduces new universal pre-shredder for waste processing applications

BHS-Sonthofen’s new RAPAX pre-shredder is suited for processing various metal fractions, commercial waste, industrial waste and construction waste. The flexible, smart control system also ensures efficient pre-shredding in every running direction.

Functional design elements make the RAPAX sturdier and easier to maintain, such as the intersecting struts on the funnel, which ensure greater stability. The surface, wall thickness and shape of the funnel are also sturdy and feature precise edges to avoid signs of wear and material build-up. The two planetary gears with belt drive are positioned side by side, as opposed to diagonally opposite, to save space.

Equipped for different applications BlowMoulding Circulareconomy BioFiber

BHS offers the RAPAX pre-shredder in a number of different designs and sizes to ensure that it can optimally process a wide range of input materials, ranging from light scrap metal, electrical and electronic waste, industrial and commercial waste, to worn-out drywall and asphalt tiles.

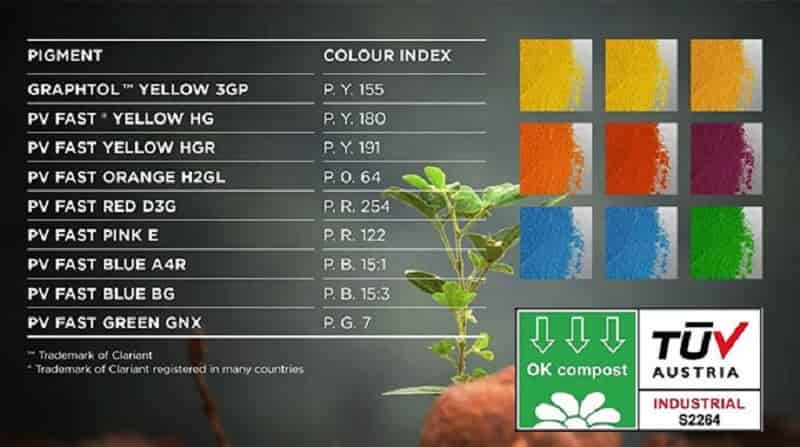

-Clariant pigments certified for use in compostable plastic

Clariant’s Pigments unit has received OK compost Industrial certification by TÜV Austria for its range of pigments in response to the increasing use of compostable polymers in plastic products to meet sustainability targets and fulfill commitments to the plastics circular economy. BlowMoulding Circulareconomy BioFiber

Clariant certified pigments can be used to color plastic products, including packaging, intended to be compostable.

Nine selected products in Clariant’s PV Fast and Graphtol ranges now feature the label OK compost Industrial, that fully meets the requirements of the European Union EN 13432: 2000 standard when not used above the maximum concentration in the final application.

‘We are proud of this development that is part of our strategy to offer solutions for more sustainable packaging and to strengthen our product portfolio,’ said Andreas Buder, technical marketing manager, Plastics at Clariant. ‘This certification allows our customers to use bright colors in their biodegradable products since they are suitable for industrial composting.’ BlowMoulding Circulareconomy BioFiber

The PV Fast and Graphtol range of pigment powders are organic pigments. Both product ranges are used in several applications in the consumer goods sector such as sensitive food contact packaging, plastics tableware/dishware or toys. Label opens new color opportunities to masterbatch and packaging producers and helps the fast-moving consumer goods (FMCG) industry fulfill its sustainability commitments.

-Lion Alternative Energy files patent for nano-carbon coating to support the hydrogen economy

Lion Alternative Energy has filed a provisional patent application with the US Patent and Trademark Office (USPTO) for its nano-carbon coating technology which supports the safe transportation of hydrogen. BlowMoulding Circulareconomy BioFiber

The clean technologies company on Monday (July 19) confirmed the news, stating that its nano-carbon coating technology deposits layered nano-hydrocarbon structures with concentrations of up to 90% or more in the diamond phase without depressurisation of the working chamber.

By efficiently and reliably apply the coatings customers are able to the emerging hydrogen economy as well as for medical implants and devices, whilst reducing the risks of corrosion that could cause fires and explosions.

Once converted into a US non-provisional application, the patent application will provide protection for Lion Alternative’s nano-carbon coating technology, effective upon a grant of a US patent.

Lion Alternative also plans to pursue an international (PCT) patent application, from which national stage patent applications can be submitted in both industrial jurisdictions and developing countries around the world.

-German waste management giants announce joint venture

Germany-based EEW Energy from Waste GmbH (EEW) and DSD – Duales System Holding GmbH & Co. KG have announced plans to jointly develop a a procedure for processing mixed plastics and other residues from consumer packaging waste. The aim is to obtain large quantities of plastic waste for chemical recycling that currently cannot be recycled for technical or economic reasons. BlowMoulding Circulareconomy BioFiber

The two companies have agreed to establish a joint venture. By the end of 2021, the aim is to develop a technically and economically viable procedure for processing 200,000 metric tons of plastic waste per year in a plant to be built and operated jointly. The input materials are to be obtained from DSD and EEW’s waste streams.

Michael Wiener, CEO Der Grüne Punkt, explains: “With this joint venture, we are creating a solution for plastic waste which cannot be recycled but which generally end up being incinerated in cement or waste incineration plants.

-DSD enters chemical recycling

Together with EEW Energy from Waste, DSD plans to develop a new process for processing mixed plastics and sorting residues. BlowMoulding Circulareconomy BioFiber

Plastic waste that cannot yet be recycled for technical or economic reasons will reportedly be processed for chemical recycling. According to system operator DSD and plant operator EEW, they have agreed to establish a joint venture for this purpose and announced that they will develop a process by the end of this year to process up to 200,000 tons of plastic waste annually in a jointly built and operated plant. Input materials are to be sourced from DSD and EEW waste streams. “With this joint venture, we are creating a convincing solution for plastic waste for which recycling is still out of the question today,” commented Michael Wiener (photo), CEO of Der Grüne Punkt. According to Bernard M. Kemper, CEO of EEW GmbH, their cooperation is the first time companies in the field of material and energy recycling have joined forces “to strengthen chemical recycling and thus further close the raw material cycle.”

BlowMoulding Circulareconomy BioFiber