BOPET Film

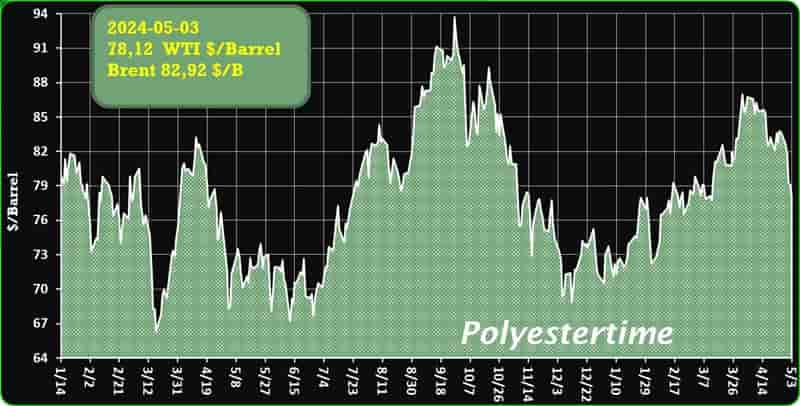

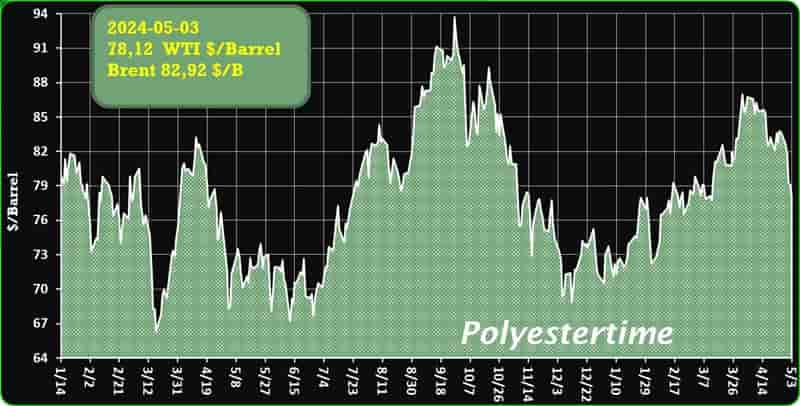

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

BOPET Film Market in China Rebounded Amidst Upward Costs Pressure

In a surprising turn of events, the BOPET Film market in China experienced a decent rebound during the first half of April 2024 on the back of higher production costs that tightened supply and intensified buying pressure. This resulted in a significant cost increase for producers and downstream industries that rely on BOPET Film for their operations.

Following a drone attack on a major Russian oil refinery and simmering geopolitical tensions in the Middle East, Crude oil prices experienced a sharp rise during the middle of April 2024. BOPET Film

This, in turn, triggered a domino effect that impacted the cost of downstream petrochemicals, including PET, a key raw material for BOPET Film production. Even before the oil price hike, the BOPET Film market in China was grappling with a supply crunch. The primary port inventories in East China decreased by 7.3% to approximately 778k tons before the national holiday on April 5th April 2025. Meanwhile, the rise in PET feedstock costs translated into higher production costs for BOPET Film manufacturers. Faced with this financial squeeze, manufacturers had a minimum choice but to raise their final product prices to maintain profitability. BOPET Film

More…

BASF Venture Capital increased investment in Phomera Metamaterials Inc.

- BASF Venture Capital (BVC) announced today that it has invested in Phomera Metamaterials Inc. during its Series A financing round

- This investment will mainly be used for capacity expansion, downstream market development, and product upgrades at Phomera

BASF Venture Capital (BVC) announced today that it has invested in Phomera Metamaterials Inc. (Phomera) during its Series A financing round, to further promote the development of the photonic crystal metamaterial industry. This investment will be mainly used for capacity expansion, downstream market development, and product upgrades at Phomera. BOPET Film

Established in 2015, Phomera Metamaterials Inc. is a leading research and manufacturing company in the field of photonic crystal metamaterials. Photonics crystal metamaterial is an artificially synthesized material formed by arranging polystyrene (PS), polymethyl methacrylate (PMMA), or silica microspheres into periodic structures. By constructing a pre-designed three-dimensional structure through multiple layers of microspheres, it can generate various functions such as material tuning, conductivity & magnetic control, and color change by modulating electromagnetic waves. With its outstanding performance, environmental friendliness, and cost-effectiveness, photonic crystal metamaterials can replace many traditional materials and be applied in various commercial scenarios, with broad development prospects. BOPET Film

Following a resolution taken by the Executive Board, Krones aims to reduce its greenhouse gas emissions to net zero by 2040 – along the entire value chain.

“In view of the latest forecasts issued by climate researchers, each and every one of us needs to know that our planet has reached a dangerous turning point,” explains Krones’ CEO Christoph Klenk. “As far as climate change is concerned, all of us – businesses, politicians, individuals – are in this together. Even now, it is still possible to protect the conditions necessary to ensure humankind’s continued existence, and we must therefore take the chance while we still can.”

Following the standard of the Science Based Targets initiative (SBTi), the Krones Group intends to cut its greenhouse gas emissions by 90 per cent along the entire value chain (Scopes 1 to 3) and neutralise the remaining ten per cent by 2040. 2019 is the base year for that and also for the near-term targets already validated by the SBTi. Krones submitted its net-zero target to the Science Based Targets initiative in early April, and the Krones sustainability team expects final validation to be issued by autumn this year.

More…

DOMO Chemicals responds to surging demand in China with new TECHNYL® polyamide production plant

- Opening of new Jiaxing plant bolsters commitment to stay close to customers

- Potential capacity up to 50,000 tons to serve growing demand for automotive, electronics, energy, and industrial and consumer goods sectors

- TECHNYL® polyamides provide intelligent solutions for China’s growth markets in the green energy and mobility sectors

Jiaxing, [29.04.2024] – DOMO Chemicals, a global leader in engineered technical materials, proudly inaugurates its newest plant in Haiyan, Jiaxing, Zhejiang, China. This significant milestone reinforces DOMO’s determination to meet rising demand in the Chinese market for its TECHNYL® polyamide-based intelligent solutions.

The €14 million (RMB 100 million) investment represents a potential doubling of DOMO’s commitment to the Chinese market, with the new plant capable of increasing the current capacity of 25,000 tons of TECHNYL® polyamides to 35,000 tons and eventually 50,000 tons in the long term. BOPET Film

Covering an area of 40,000 square meters, the state-of-the-art facility underscores DOMO’s unwavering commitment to providing high quality products and services to its customers in key sectors such as automotive, electronics, energy, industrial and consumer goods.

More…

US Caprolactam Market Faces Challenges with Moderate Supply and Low Demand

The US Caprolactam market experienced a marginal increase in April, with raw material benzene prices remaining steady, providing limited support to the downstream Caprolactam sector. Despite this, the overall market conditions remain challenging, with supply levels categorized as moderate and demand staying relatively low. As a ripple effect, the cost of Caprolactam in the US market rose by approximately 1% in April compared to the preceding month’s data. BOPET Film

One of the key factors contributing to the market’s stability has been the steady prices of benzene, a crucial raw material in Caprolactam production. The steady benzene prices have helped to keep production costs in check for Caprolactam manufacturers, preventing any significant upward pressure on prices.

However, despite the modest cost environment, new orders for Caprolactam have declined in the US market this month. Manufacturers have reported a drawdown of their stock of purchases in April, indicating a cautious approach to inventory management amidst uncertain market conditions. BOPET Film

This decline in new orders reflects the subdued demand for Caprolactam in the US, which has been a persistent trend in recent months.

More…

LYB to build integrated plastic waste recycling hub in Knapsack

LyondellBasell (LYB) has secured a location for an integrated plastic waste recycling hub south of an existing industrial park in Knapsack, Germany, signing a land lease agreement with YNCORIS GmbH & Co. KG. The hub is planned to combine various advanced sorting and recycling operations, helping to address the plastic waste challenge and grow the circular economy. The project will be developed in phases; the initial phase will see the construction of an advanced sorting facility that will process mixed plastic waste to produce feedstock for mechanical and advanced recycling. BOPET Film

This mixed plastic waste is not recycled today and mostly sent to incineration for energy recovery.

In total, the integrated recycling hub will cover an area equivalent to 20 soccer fields. It is expected that the hub’s initial advanced sorting facility will start operations in the first quarter of 2026. These new investments support the company’s ambition to produce and market at least 2 million metric tons of recycled and renewable‑based polymers annually by 2030. BOPET Film

More…

Namibia recycling facility doubles capacity

Launch of cutting-edge recycling facility in Namibia

A N$24 million (over US$1.2million) investment through a partnership between Coca-Cola Beverages Africa (CCBA) (www.CCBAgroup.com) in Namibia and Plastic Packaging has culminated in the opening of a new polyethylene terephthalate (PET) flaking plant in Okahandja which will double the capacity of the only mechanical recycler of plastic waste in the country. The plant was officially […] BOPET Film

A N$24 million (over US$1.2million) investment through a partnership between Coca-Cola Beverages Africa (CCBA) (www.CCBAgroup.com) in Namibia and Plastic Packaging has culminated in the opening of a new polyethylene terephthalate (PET) flaking plant in Okahandja which will double the capacity of the only mechanical recycler of plastic waste in the country.

The plant was officially inaugurated by the Minister of Environment, Forestry and Tourism, Pohamba Shifeta.

“The Coca-Cola system aims to drive systemic change through a circular economy for packaging. We are leading the industry to help collect and recycle a bottle or can for every one we sell by 2030. BOPET Film

More…

BOPET Film

Plastic pyrolysis – Chinaplas 2024, the premier international fair for the plastics and rubber industry, celebrated a remarkable return to Shanghai after a six-year hiatus, setting new attendance records 02-05-2024