Carbon fiber – New method of recycling carbon fiber shows potential for use in more advanced products 31-10-2023

Carbon fiber

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

New method of recycling carbon fiber shows potential for use in more advanced products

As manufacturing and technology continually take steps forward, products are using more advanced materials and becoming more sophisticated, but also more complicated.

This presents a problem when these products reach the end of their useable life, because they’re either difficult or expensive to recycle, or both.

For example, as the world transitions to electric vehicles, disposing of their used batteries, some made with highly toxic materials, will be a challenge.

As it stands, many advanced products either end up in landfill or incinerated, which is a waste of valuable resources and harmful to the planet. Carbon fiber

One material that has been difficult to recycle is carbon fiber.

However, a UNSW Canberra researcher has developed a method to recycle it in a way that not only wastes less of the material, but also uses less energy and leaves more of it intact and able to be turned into more useful new products.

Carbon fibers are thin strands of carbon that are exceptionally strong and lightweight. The fibers are combined with plastic to create a composite that can be used to construct a variety of products. Carbon fiber

Carbon fiber is commonly used to build aircraft, wind turbines, and it is the primary material used in Formula 1 race cars, which need to be as light as possible to increase performance. You might encounter carbon fiber in high-end bicycles or other sporting equipment such as hockey sticks or tennis racquets.

Fairmat, a Leading French Deeptech Carbon Fiber Recycling Company, Showcases Tech-Driven Solutions at CAMX 2023

Fairmat, a prominent French deeptech company specializing in carbon fiber composite recycling and product co-design, is set to showcase their innovative solutions at CAMX, the largest and most comprehensive composites and advanced materials event in North America. Their participation in this renowned expo will spotlight Fairmat’s tech-enabled manufacturing processes, addressing carbon fiber waste challenges in the United States.

“At Fairmat, we are closing the loop on carbon fiber composite. Our Ecosystem is a fully-integrated infrastructure that spans the entire value chain, from research and development to design and manufacturing. Carbon fiber

I am excited to announce that we will be showcasing our solutions, engineering expertise, and co-designed products at CAMX for our US customers,” shares Benjamin Saada, Founder & CEO of Fairmat.

CAMX 2023

For the first time, Fairmat will exhibit their solutions at CAMX, October 30 to November 2, underscoring their commitment to helping US industries decarbonize and assisting clients in co-designing breakthrough sustainable products. Carbon fiber

“We are proud to be at CAMX for the first time this year. At Fairmat, we want to play a vital role in helping US composite manufacturers decarbonize and aiding local US brands in designing new products using our innovations,” states Antoine de Turckheim, US Country Manager, Fairmat. Booth location: Georgia World Congress Center, BB30, Building C, Level

Proximity to Material & Clients

Emphasizing a global-to-local approach, Fairmat’s presence at CAMX reflects their focus on being closer to carbon fiber material hubs and clients. This aligns with the company’s values and goals to reduce their carbon footprint. Building on its success in France, Fairmat is creating a high-tech closed-loop ecosystem. Carbon fiber

HTPA High Temperature Nylon: A Booming Industry for the Future

High temperature nylon (HTPA) is a special type of nylon engineering plastic that can withstand temperatures of 150°C or higher for a long time1. It has excellent mechanical properties, chemical resistance, and dimensional stability, making it suitable for various applications in automobile, electronics, LED, machinery, and other industries2.

The global HTPA high temperature nylon market is expected to witness extraordinary growth by 2030, driven by the increasing demand for high-performance materials in various end-use sectors. According to a report by ReportsnReports, the global HTPA high temperature nylon market size is projected to reach US$ million by 2028, at a CAGR of % from 2022 to 20283. The report also analyzes the market by type, application, region, and key players. Carbon fiber

The major types of HTPA high temperature nylon are glass fiber reinforced type and flame retardant type. The glass fiber reinforced type segment is expected to dominate the market in terms of revenue and volume, due to its superior strength, stiffness, and heat resistance. The flame retardant type segment is also anticipated to grow at a significant rate, owing to its enhanced safety and environmental benefits4.

The main applications of HTPA high temperature nylon are automobile, electronics, LED, machinery, and others. The automobile segment is projected to account for the largest share of the market, as HTPA high temperature nylon is widely used in engine components, transmission parts, fuel systems, and other parts that require high temperature resistance and durability. Carbon fiber

The electronics segment is also forecasted to grow rapidly, as HTPA high temperature nylon is used in connectors, switches, sensors, and other electronic devices that operate in harsh environments2.

The global HTPA high temperature nylon market is geographically divided into North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. Asia Pacific is expected to be the fastest-growing region in the market, due to the rising industrialization, urbanization, and consumption of HTPA high temperature nylon in China, India, Japan, South Korea, and other countries. Carbon fiber

North America and Europe are also expected to hold significant shares of the market, due to the presence of major manufacturers and consumers of HTPA high temperature nylon in these regions5. Carbon fiber

The global HTPA high temperature nylon market is highly competitive and fragmented, with the presence of several key players such as DuPont, DSM, Solvay, MGC, Mitsui Chemicals, BASF, Kuraray, EMS Chemie Holding, Kingfa, etc. These players are engaged in various strategies such as product innovation, expansion, mergers and acquisitions, partnerships, and collaborations to gain a competitive edge in the market6.

The global HTPA high temperature nylon market is expected to face some challenges such as high production cost, limited availability of raw materials, and environmental regulations. Carbon fiber

However, these challenges are likely to be overcome by the development of new technologies, products, and applications that can enhance the performance and reduce the cost of HTPA high temperature nylon. Moreover, the emergence of new markets and opportunities in emerging economies will also provide impetus for the growth of the HTPA high temperature nylon industry in the future2. Carbon fiber

New report blasts the limitations of pyrolysis technology, dubbed “miracle” by industry

A new report released today has criticised a so-called “miraculous” method of plastic waste management that has been shown to be misleading in its efficacy.

Touted as a solution, pyrolysis – technology that heats up plastic waste in the absence of oxygen – produces a type of oil that industries argue can be transformed back into ‘virgin-like’ plastic. Carbon fiber

However, this latest report published by the environmental network Zero Waste Europe underlines the limitations of pyrolysis oil. Incompatibility with different plastic types, low yield, and contamination of pyrolysis oil means it must be diluted by a petroleum-based mixture, in some cases by a ratio of over 40:1.

The report, “Leaky loop “recycling”: A technical correction on the quality of pyrolysis oil made from plastic waste” argues that for pyrolysis oil to be used in the production of recycled plastic, it should either apply multiple energy-intensive purification steps or highly dilute the oil with virgin petroleum naphtha. Both options are not in line with the ambitions of the EU Green Deal.

Discussions underway to define a harmonised European approach to end-of-waste criteria for plastic will continue until 2025, when the review is foreseen to be adopted. Such a definition is crucial for pyrolysis as industry interests are to classify pyrolysis oil as a product. Decision-makers should not overlook the toxic compounds and purification requirements needed for pyrolysis oil and lower safety standards for the sake of developing a circular economy. Carbon fiber

Lauriane Veillard, Chemical Recycling and Plastic-to-Fuels Policy Officer, states:

“If pyrolysis oil is reclassified as a product instead of being classified as waste, as industry demands, it must meet EU requirements. We cannot afford to accept haphazardous legislation that undermines a true circular economy. Our north star should be the protection of the environment, human health and the public trust. These values should form the basis of different discussions on plastic recycling-related issues, like calculating recycled content and defining end-of-waste criteria.”

Low oil yield presents a significant problem with pyrolysis technology. Even in a best case scenario, only 2% of the plastic waste fed into pyrolysis will actually make it into the “recycled” product, the report found. Carbon fiber

The Growing Problem of Misleading Biodegradable Plastics

In recent years, the issue of plastic pollution has gained significant attention, with experts raising concerns about the environmental impact of plastic waste. A study published in the journal Science revealed that only 9% of plastic produced had been recycled, while a staggering 79% was left to rot in landfills or garbage dumps. Moreover, approximately 10% of this plastic waste eventually reached the ocean, contributing to the global problem of marine pollution.

However, the situation has only worsened since that study was conducted. Despite the implementation of “zero plastic” policies by some countries, the production and disposal of plastic continue unabated.

Factories continue to generate a staggering 400 million tons of plastic each year, exacerbating the accumulation of plastic waste. Carbon fiber

As a result, contamination by microplastics, which are fragments of plastic less than 5 millimeters in length, has emerged as one of the most pressing environmental concerns alongside the climate crisis. These microplastics can be found everywhere, from land and sea to the air. They have even been found in the human body, circulating in the bloodstream and accumulating in vital organs.

In an effort to address the issue, there have been attempts to develop biodegradable plastics as an alternative to conventional plastics. However, a recent investigation conducted by researchers from the Federal University of São Paulo’s Institute of Marine Sciences (IMAR-UNIFESP) has revealed that some of these claims are misleading.

The study examined 49 different products, including plates, cutlery, cups, and straws, all marketed as biodegradable. Shockingly, none of the products met the minimum requirements to be considered truly biodegradable. They were predominantly made of a type of material known as oxo-degradable plastic, which does not degrade under normal environmental conditions.

Instead, these plastics fragment into smaller pieces, contributing to the formation of microplastics that persist for decades. Carbon fiber

Italy’s Pirelli to make tyres in Saudi Arabia with Saudi wealth fund

Italy’s Pirelli ) has signed a joint venture with Saudi Arabia’s Public Investment Fund (PIF) to build a tyre manufacturing facility in the country, the two groups said on Thursday.

The deal – for a total investment of $550 million – will make Pirelli the first tier 1 tyre maker to directly source production in Saudi Arabia, which is trying to diversify its economy away from oil. Carbon fiber

PIF, Saudi Arabia’s $700 billion sovereign wealth fund, will hold a 75% stake in the new JV, with Pirelli holding the remaining 25% and providing the technical and commercial support for the development of the project, the two groups said.

The project will not impact Pirelli’s deleveraging targets to 2025, they added.

The plant is expected to start producing in 2026 and is set to reach a production capacity of 3.5 million units.

It will manufacture high-quality tyres for passenger vehicles under the Pirelli brand, as well as market tires under a new local brand mainly aimed at the domestic and regional market, it added.

Founded in 1872, Pirelli now specialises in high-end tyres for premium carmakers like Ferrari , Porsche and BMW and is the sole supplier for Formula One cars.

Saudi Arabia is boosting its manufacturing capabilities in the automobile sector and aims to produce more than 300,000 cars annually by 2030. Carbon fiber

PE, PP ‘highly challenged’ by Europe, new capacity while US exports a positive – LyondellBasell

Global polyethylene (PE) and polypropylene (PP) markets will continue to see headwinds from weak European demand and new capacity through at least H1 2024, but positive signs include strong US PE exports and some improvement in China, executives from LyondellBasell said. Carbon fiber

“[US] PE exports have gone up during the past quarter, and that of course is a positive sign. But one also needs to look at additional capacity that has come into the market or that has not really hit the market because of… some technical difficulties,” said Peter Vanacker, CEO of LyondellBasell, on the company’s Q3 earnings call.

He expects the European market overall to remain “highly challenged” on weak demand coupled with rising feedstock and energy costs which will compress margins.

US exports are being supported by a high oil/gas ratio that is expected to continue, especially with volatility around oil markets and gas production being relatively robust, said Ken Lane, executive vice president, Olefins and Polyolefins (O&P) at LyondellBasell.

“We do feel good about what’s happening in the North American market,” said Lane.

“Europe is going to continue to be very challenged in terms of demand. That is still significantly down, mainly because of the inflation impact, but also the margins are challenged with the higher naphtha pricing,” he added. Carbon fiber

New capacity will be the key factor to watch in 2024, he pointed out.

“We’re still going to see more capacity coming online next year and that’s why we’re going to be kind of bouncing along the bottom overall as an industry in H1 of next year,” said Lane.

“The hope is that at the back end of next year we start to see some recovery as market growth comes back to absorb the additional capacity. But there’s going to continue to be pressure from new capacity coming in, and that’s going to be the biggest ‘watch-out’ for us,” he added.

CHINA SLOWLY IMPROVING

In China, overall markets appear to be slowly improving as targeted stimulus measures provide some benefit. Carbon fiber

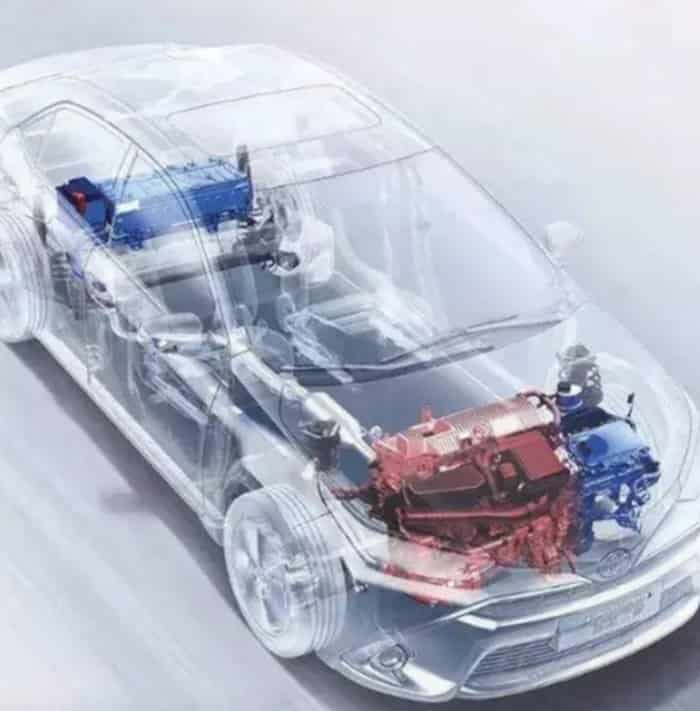

“We don’t see the construction market picking up yet but automotive has seen a 10% year on year increase and EVs (electric vehicles) has been closer to 40%,” said Vanacker.

“But on the other hand, we see that consumers continue to save a lot of money. With more and more of these incentives, one would expect confidence will grow in the population which then would influence their spending on durable goods as well,” he added.

Bottles-to-fabric – Teesside welcomes Mura Technology’s first HydroPRS plant 30-10-2023

Carbon fiber