Chem-recycling – Plastic-eating-enzyme 28-06-2022 - Arhive

Chem-recycling – Plastic-eating-enzyme

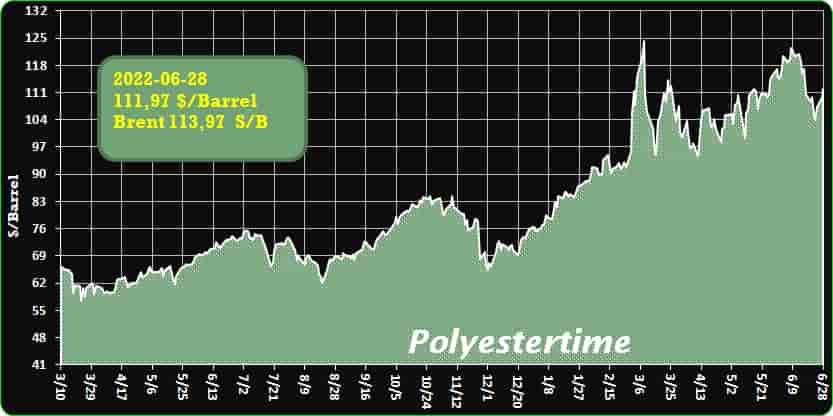

Crude Oil Prices Trend

-Advanced Recycling Has Waste Plastic’s Number

Currently not all plastics are easily recycled or worth the ROI to do it, but three things are bringing the circular economy closer to fruition — artificial intelligence, a plastics-eating enzyme, and, yes, boundless inventory.

Much as the internet of things (IoT), artificial intelligence (AI), and cryptocurrency are morphing into something different by the day, the recycling industry is busy with its own version of Transformers as it comes to terms with the need to recycle all seven plastics types. Chem-recycling – Plastic-eating-enzyme

Public perception has it that we’re drowning in plastic waste: We are told that the oceans will contain by weight more plastic than fish by 2050 and that we ingest the equivalent of a credit card (5 g) of plastic each week.

In spite of the best efforts of the media, politicians, and legislators to maintain their fear-based dogma, a bit of research puts the lie to these statements. The myriad reasons for such false narratives are beyond the scope of this article.

San Francisco-based Brightmark founder and CEO Bob Powell sums up the exciting future that lies ahead for all seven plastic types. He states that because of their chemical make-up, “plastics 3 to 7, in particular, are not easily recycled with other technologies, and typically end up in landfills, incinerators, or, sadly, in our oceans. We’re proud to have a proven, breakthrough closed-loop solution for transforming these raw materials back into useful products.”

-Carbon Capture Offers Great Advantages, Presents Big Challenges

The US Department of Energy’s $3.5-billion investment in carbon removal projects and similar initiatives worldwide are rapidly advancing the technology, but significant hurdles remain before it can be deployed at The harmful effects of climate change, caused by steadily increasing carbon emissions, are being felt worldwide.

While companies and research groups struggle to develop new technologies to reduce carbon emissions, some scientists are looking beyond a net-zero emission goal to a beyond-zero future that actively reduces the amount of carbon dioxide in the atmosphere.

This is known as carbon capture, the removal and subsequent storage or conversion of carbon dioxide. Chem-recycling – Plastic-eating-enzyme

It is a nascent industry and also is referred to as direct air carbon removal, carbon utilization, carbon dioxide utilization, or carbontech.scale.

The harmful effects of climate change, caused by steadily increasing carbon emissions, are being felt worldwide. While companies and research groups struggle to develop new technologies to reduce carbon emissions, some scientists are looking beyond a net-zero emission goal to a beyond-zero future that actively reduces the amount of carbon dioxide in the atmosphere.

This is known as carbon capture, the removal and subsequent storage or conversion of carbon dioxide. It is a nascent industry and also is referred to as direct air carbon removal, carbon utilization, carbon dioxide utilization, or carbontech.

The U.S. Department of Energy announced in May a $3.5-billion investment in direct air carbon removal projects, in an effort to encourage an industry that might help get the world’s planet-warming emissions under control.

Direct air carbon removal projects are similar to giant vacuums that capture carbon dioxide from the air and contain it. These projects then use chemicals to remove the gas from the air and store it in underground rocks or use it in various materials, such as concrete or chemicals.

]Nature removes carbon dioxide from the atmosphere on its own in its forests, bogs, and oceans. But this natural process occurs at a rate that is far too slow to keep up with worldwide fossil fuel emissions. Chem-recycling – Plastic-eating-enzyme

The DOE’s $3.5-billion project, funded by the bipartisan infrastructure law, aims to develop four direct air capture hubs, each capable of removing more than 1 million tons of CO2 per year. Removing 1 million tons of CO2 per year is equivalent to taking 200,000 gas-powered cars off the road.

-US Eastman considers building PET chem-recycling complex in Texas

Eastman is considering developing a chemical recycling project in Texas that would break down polyethylene terephthalate (PET) and repolymerise the resulting monomers into plastic, according to an application for a tax break.

Eastman would develop the project at its complex in Texas City. It would include a processing unit that would sort out PET from plastic waste, according to an application it made with the Texas City school district.

Another unit would break down the recovered polyester resin into monomers by using methanolysis, according to the application. A third unit would repolymerise the monomers to produce PET.

The project could produce more than 150,000 tonnes/year of plastic from recovered polyesters and mixed textiles, it said in the application. The value of the investment could be $850m. Chem-recycling – Plastic-eating-enzyme

Eastman estimates that the board of the school district could ratify a final agreement on the tax break in the fourth quarter of 2022. Construction could start in the fourth quarter of 2024. Commercial operations could start in the fourth quarter of 2026.

If Eastman builds the project, it would be similar to the one it is building in Kingsport, Tennessee. It should complete that project by the end of the first quarter of 2023.

Eastman said its decision to develop the Texas City project would be heavily influenced by the tax break.

-New funding for plastic-eating enzyme research

The research is to look for new naturally occurring enzymes that can degrade plastic back into its chemical building blocks.

The University of Portsmouth has been awarded funding to look for new plastic-eating enzymes. Chem-recycling – Plastic-eating-enzyme

Angie Beckett, a Specialist Research Technician in the University’s Centre for Enzyme Innovation, will receive £25,000 to use genome sequencing to search for new naturally occurring enzymes that have the potential to degrade plastic back into its chemical building blocks.

The University is pioneering the use of enzymes to digest plastics such as polyethylene terephthalate (PET). PET is the most common thermoplastic, used to make single-use drinks bottles, clothing and carpets and it takes hundreds of years to break down in the environment.

The plastic-eating PETase enzyme breaks down PET back into its building blocks, creating an opportunity to recycle plastic infinitely and reduce plastic pollution and the greenhouse gases driving climate change. The University hopes to create similar cycles for other types of commonly used plastic.

“Nature often holds the key to these problems, so we intend to take samples from the environment and see if we can find the answers. Using sequencing to look at the DNA of bacteria living in close contact with plastic, we hope to discover new plastic-eating bacteria. I’m very excited to do this research and see what we can find.”

Angie said: “Although we have discovered enzymes that can break down PET, there is still some improvement needed to make it ready for plastic-recycling. There are also many other types of plastic that we need to figure out how to break down. Nature often holds the key to these problems, so we intend to take samples from the environment and see if we can find the answers. Using sequencing to look at the DNA of bacteria living in close contact with plastic, we hope to discover new plastic-eating bacteria. I’m very excited to do this research and see what we can find.” Chem-recycling – Plastic-eating-enzyme

-Circular economy for plastic in Malaysia — Are we on track?

PLASTIC, dubbed a miracle invention due to its durability and versatility, has made our lives substantially easier. However, 60 years after its invention, managing plastic waste has become one of the planet’s biggest problems.

The statistics are alarming, with mass production and consumption of plastic on the rise since 19501. According to a report published by WWF-Malaysia (World Wide Fund for Nature-Malaysia), post-consumer plastic waste generation in Malaysia is estimated to be more than one million tonnes (1,070,064 tonnes, to be precise).

Plastics can in fact be reused and recycled into usable products. However, 81% of the material value of plastics is lost due to failure to recover the material. This results in US$1.1 billion (RM4.86 billion) of potential material value lost to Malaysia’s economy, as reported in a study by the World Bank. Chem-recycling – Plastic-eating-enzyme

Just like any other packaging materials, plastic requires proper segregation, collection, material recovery, treatment and final disposals. Currently, the largest segment of demand growth for plastic production is predominantly single-use plastic.

Encouragingly, there have been global movements to advocate for a transition from a linear plastic system to a circular one. A circular economy for plastic builds on three key principles — the elimination of waste and pollution, circulation of materials at the highest value for as long as possible, and regeneration of resources.

-New EDF tool reveals toxic chemicals in common food packaging

Web tool breaks down packaging types, materials and toxins

New research from the Environmental Defense Fund (EDF) confirms that hundreds of toxic chemicals are used in the making of food packaging. Toxic chemicals come in direct contact with our food through everyday packaging materials, increasing health risks for consumers and reputational and financial risk for major brands.

EDF analyzed where toxic chemicals are used today by companies and which ones are used most often. It found that over 80% of the chemicals that are most toxic to human health and the environment are used in packaging materials like paperboard, plastics and inks. Chem-recycling – Plastic-eating-enzyme

Here’s why this matters: Toxic per- and polyfluoroalkyl substances – known as PFAS chemicals have been found in the blood of nearly every person in the U.S. As scientists look to understand exposures, food packaging is emerging as a potential source. All of this exposure is impacting our planet and human health. Many companies are unaware of the chemicals in food packaging.

For companies, it’s a growing business risk: Earlier this year, Burger King was among companies being sued for the presence of toxic ‘forever chemicals’ in their fast-food packaging. This risk is only going to increase as we see more regulations at the state level against the use of chemicals in products, including in places like Washington, announced this week. Retailers who wait for more stringent food packaging regulations to be enacted will have more work down the line playing catch up.

Where do we go from here? EDF turned the analysis into an easy-to-use web-based tool to help companies make environmentally sustainable and safer purchasing decisions. Companies can click on common food containers, like a pizza box, and see what materials it’s made out of and what chemicals those materials contain. With this data at their fingertips, companies can more easily identify hotspots and work with suppliers to create safe, circular and more environmentally sustainable packaging.

Toxic chemicals are used in the making of common food packaging materials. These toxic chemicals can then migrate into food, and many companies aren’t aware that their packaging contains harmful chemicals or what is required to make a proactive pivot toward safer food packaging. Chem-recycling – Plastic-eating-enzyme

This tool is designed to help companies get started on working with their suppliers to identify which toxic chemicals exist in the food packaging they produce and how they got there. Information provided on this website builds upon the work of the SUM Decelerator, creator of the Understanding Packaging (UP) Scorecard and the Food Chemicals of Concern (FCOC) List. EDF is a member of the SUM Decelerator.

-This Road Wirelessly Charges Electric Cars as They Drive

Coils in the asphalt charge EVs the same way the dock on your bedside table wirelessly charges your phone

As prices drop and availability increases, some of the last road blocks to mass adoption of electric vehicles is range anxiety and charging times. But a prototype test track in Italy solves both of those issues by borrowing the same technology that makes it easy to charge your smartphone without wires. Chem-recycling – Plastic-eating-enzyme

Although the earliest EVs were often recommended for shorter daily commutes or city driving because of their limited range, there are now many options promising well over 300 to 400 miles of travel before the vehicle’s batteries need a charge. But what still complicates a long road trip in an EV is that even the fastest charging stations require at least half an hour to replenish rechargeable batteries, and usually much longer than that depending on the range of the vehicle. Compare that to filling up a tank with gasoline, which takes just a couple of minutes, and it makes sense why some drivers are still hesitant to go electric.

Ranges and charging times will inevitably improve over time, but other companies are looking into completely different solutions that could eliminate charging pit stops altogether. Chem-recycling – Plastic-eating-enzyme

Stellantis isn’t exactly a household name as far as car makers go, but it’s the parent company for iconic brands like Jeep, Chrysler, Dodge, Ram, and even Maserati.

As with any car maker hoping to stay relevant over the next few decades, it’s investing heavily into research surrounding electric vehicles, and recently unveiled a unique new test track in Chiari, Italy, called the “Arena del Futuro” circuit (Arena of the Future) that could potentially allow EVs to run laps forever without ever needing to stop and charge.

-Facing plight and moving forward by VSF-weakening expectation

China’s economic development is facing triple pressure of demand contraction, supply shock, and weakening expectation—by Premier Li Keqiang at the Fifth Session of the National People’s Congress on Mar 5, 2022.

Premier Li summed up the current pressure on economic development and accurately predicted the current situation of the manufacturing industry, which is also the status quo of VSF industry. When we review the market changes in the first five months of 2022, the core elements basically rely on the three points. Chem-recycling – Plastic-eating-enzyme

Weakening expectation

Compared with the two points (supply shock and demand contraction) mentioned before, the quantification of expectation is more difficult, but we can feel the objective influence of expectation.

Global economy

From a macroeconomic perspective, the IMF in Apr lowered the global economic growth rate of 2022 from 4.4% in 2021 to 3.6%.

The World Bank in Jun downgraded the global economic growth in 2022 to 2.9% from 4.1%.

OCED in June downgraded global growth of 2022 to 3.0% from 4.5%.

It is rarely seen that the major institutions significantly downgrade economic growth at the same time, and they warn that the world may experience stagflation occurring in the 1970s. Chem-recycling – Plastic-eating-enzyme

Based on the distribution of global wealth, some institutions even predict that the challenges facing by the global economy are likely to exceed those in the 1970s.

Chem-recycling – Plastic-eating-enzyme