CrudeOil Polyolefins RePackaging 06-02-2020 - Arhive

CrudeOil Polyolefins RePackaging

Crude Oil Prices Trend

-Faurecia completes acquisition of 50:50 JV with Continental

Following approval from the appropriate regulatory bodies, Faurecia has announced that it has completed the acquisition of the remaining 50% of its SAS joint venture from Continental, a project that was announced on October 14, 2019.

SAS is a key player in complex interior module assembly and logistics with sales of around 740 million euros (Rs 5,826 crore) in 2019 and employing around 4,490 people.

This acquisition reinforces Faurecia’s ‘Cockpit of the Future’ strategy and its systems integration offer which now covers all interior modules as well as functionalities such as lighting and thermal management. Fabric Carbon Fiber RePackaging

It also strengthens Faurecia’s Just in Time plant network with 20 facilities in Europe, North and South America and China.

-China chemical production curtailed amid Coronavirus restrictions

Disruption in China caused by the coronavirus is hitting domestic chemical production as the Lunar New Year break is extended amid restrictions on movement of goods and people. CrudeOil Polyolefins RePackaging

As the government battles to contain the spread of the virus, there are reports that logistical problems, staffing shortages, and rising inventories are forcing chemical companies to cut production.

Demand is also being hit as economic activity is curtailed in some areas and downstream industries delay post-holiday restarts.

-Hengli Petrochemical announces start-up of 4th PTA line

Invista’s technology and licensing group, Invista Performance Technologies (IPT) and Hengli Petrochemical (Dalian) Company Ltd have announced the successful start-up of Hengli’s fourth purified terephthalic acid (PTA) line.

The 2.5 million tonnes per annum capacity plant is located in Changxing Island, Dalian City, Liaoning Province of China. CrudeOil Polyolefins RePackaging

The start-up, just only 22 months after the project kicked off in early March 2018, is the result of joint effort of all parties involved.

The new plant utilises Invista’s P8 PTA technology with industry leading variable cost, capital productivity, energy usage, water usage, effluent generation and footprint.

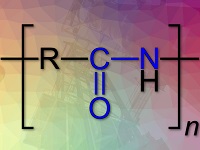

-BASF closes acquisition of Solvay polyamide

BASF has reportedly finalized its acquisition of Solvay’s polyamide (PA 6.6) business for €1.3 billion. CrudeOil Polyolefins RePackaging

According to the company, the purchase will allow BASF to develop better engineering plastics products for autonomous driving and e-mobility and improve the company’s access to growth markets in Asia as well as in North and South America.

Through the backward integration into the key raw material adiponitrile (ADN), BASF will now be present along the entire value chain for polyamide 6.6, the company said.

-Plastics Recyclers Europe report highlights new trends in PET collection and sorting

Plastics Recyclers Europe has released a new report.

A strong trend towards the use of recycled PET (rPET) due to increased demand is projected in the report by sustainability consultancy Eunomia, done in collaboration with EFBW, Petcore Europe and PRE.CrudeOil Polyolefins RePackaging

The report shows significant improvements have been made in recycling processes and with the increasing quality of materials, rPET could reach as much as 55% of total PET demand by 2030.

-Plastics power innovation at PLASTEC West

As sustainable business practices increasingly drive consumer spending habits, the plastics industry is responding to customer demand through unprecedented innovation, leveraging new technologies and materials to improve fuel efficiency in vehicles, reduce plastic waste in packaging, make buildings more energy efficient and so much more.

Such advances have led to plastics’ increasing use throughout entire industries—automotive, construction, electronics, etc.—setting up the global plastics market to surpass $720 billion by 2025, according to a report from Grand View Research.

Petrochemicals Carbon Fiber RePackaging CrudeOil Polyolefins RePackaging

-BioPak Develops Packaging Using Sugarcane Pulp

New South Wales-based packaging specialist, BioPak, has developed a sustainable alternative to conventional plastic CrudeOil Polyolefins RePackaging

packaging, which delivers a positive environmental impact.

When we buy a product, we also buy any waste associated with it.

In 2016, Australians sent 2.2 million tonnes of plastic and another 1.6 million tonnes of paper to landfill.

-Plastics recycling technology roundup

A recyclable Colgate-Palmolive tube undergoes recyclability testing in Europe, and a number of equipment innovations are up for awards.

Recovering PET from textiles: A British chemical recycling startup has launched an R&D facility to test its technology for recovering PET from mixed polyester-cotton textiles. Worn Again Technologies launched its pilot facility in Redcar, England. The company says its technology is able to produce decontaminated PET and cellulose from cotton from used textiles.CrudeOil Polyolefins RePackaging

Testing the tube: A recyclable toothpaste tube developed by Colgate-Palmolive underwent review by the European recyclability review initiative RecyClass.

-Finland’s UPM invests 550 mln in biorefinery in Germany

Finland’s UPM said on Thursday it would invest 550 million euros in a new biorefinery in Leuna, Germany, after beating market expectations with its fourth quarter earnings.

“The biorefinery will produce a range of 100% wood-based biochemicals which enable a switch from fossil raw materials to sustainable alternatives in various consumer-driven end-uses,” UPM said in a statement.CrudeOil Carbon Fiber RePackaging

Since 2013, the company has invested in research to develop new wood-based products to complement its main pulp and paper businesses.CrudeOil Polyolefins RePackaging

The biorefinery will convert solid wood into biochemicals such as bio-monoethylene glycol, which has several consumer product applications such as textiles, bottles, packaging, detergents and de-icing fluids.

-2020 Perspectives on 2030 Packaging

Should these packaging visions come to pass, packagers and their packaging technology vender/partners will continue to find efficient, sustainable ways to identify, protect, and distribute products to their consumer and industrial customers.

Metal (tin/lead) toothpaste tubes. PVC liquor bottles. Acrylonitrile-butadiene styrene apple juice cans. Cone-top tinplate beverage cans. Once these were cutting edge packaging concepts.

CrudeOil Polyolefins RePackaging