Demand plastics Fakuma plastics processing - Arhive

Demand for plastics and plastics processing remains high Demand plastics Fakuma plastics processing

Author / Editor: / Rosemarie Stahl

From 16 to 20 October, people from all over the world will come to Friedrichshafen, Germany, to see the latest trends in plastics processing. More than 1,800 exhibitors will present their international offerings at Fakuma, a leading technical event for the plastics industry.Demand plastics Fakuma plastics processing

What comes first to mind when thinking of Fakuma, the international trade fair for plastics processing? Plastics, of course. And on second thought? Probably the difficulties to get a hotel room in proximity to the trade show grounds. Although it sounds easy to get a hotel room at the border triangle at Lake Constance, the rooms are often booked up months in advance. Consequently, many visitors to the fair have to switch to private rooms and long travel times.Demand plastics Fakuma plastics processing

Other thoughts on Fakuma might include memories of traffic jams and long journeys because the access roads are congested.Demand plastics Fakuma plastics processing

Probably everyone who has ever been to the fair has a story to tell about the hotel and traffic situation, of which the organisers are also aware. Nevertheless, they do not want to change anything about the event location.Demand plastics Fakuma plastics processing

Without Friedrichshafen, Fakuma would not be the fair it is, it was said last year at the fair’s press conference.

And the organisers are probably right about that. Fakuma is and will remain a trade show with a family atmosphere.

Ultimately, the hotel and traffic situation is always a very good conversation starter, because really every visitor and exhibitor has an opinion on it.

And despite all these difficult circumstances, the trade show remains successful. Expert visitors, specialists and decision-makers journeyed to the last event in 2017 from more than 120 countries, P.E. Schall, organiser of the trade show, announced.

Some 48,375 expert visitors accepted the invitation of the roughly 1,900 exhibitors to attend the event in Friedrichshafen on Lake Constance where Germany, Austria and Switzerland meet – and the numbers continue to rise.

In addition to countless participants from Germany and elsewhere in Europe, above all the number of visitors from Asia is increasing. The propensity to invest in new machines and systems remains high, which is making itself apparent in the unbroken interest in manufacturing components and peripherals in the plastics sector.

Arburg, manufacturer of injection moulding machines for plastic processing, is not only among the biggest exhibitors of the trade show, the company is also a co-founder of Fakuma.

Commenting on last year’s edition of the trade show, Dr. Christoph Schumacher, Head of Marketing und Corporate Communication at Arburg, said: “It’s distinguished by its highly practical approach, technical expertise and a friendly atmosphere.

Personal contact plays an important role: The visitors appreciate being able to scrutinise the exhibits live and discuss them with us.

Thanks to the fact that all of our contact persons are on site at the event, international projects can also be discussed with minimal legwork.”

Innovations in materials

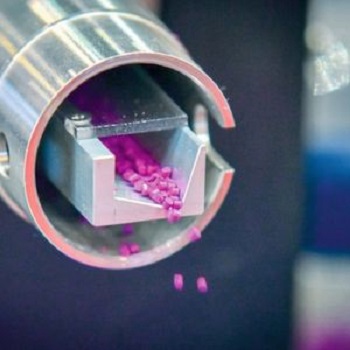

Continuous fibre-reinforced, functional plastic components with high load-carrying capacities offer tremendous lightweight-design potential for the automotive and aviation industries, as well as numerous other sectors.

Whether FRP, FFRP or CFRP is involved – solutions for the production of rugged, lightweight components will be presented at the Fakuma trade show.

There’s good reason for increasing demand for plastic components with continuous fibre reinforcement: They offer high mechanical strength with up to 25% less weight than metal components.

As a result, economic production of such parts is the focus of a diverse range of research projects.

Whereas FFRP components with a thermoplastic matrix are already being industrially manufactured and utilised, developers are currently involved with injection moulding processes for continuous fibre-reinforced, lightweight components with a thermosetting matrix.

Due to their greater resistance to cold, as well as their greater mechanical and thermal load capacities, thermosetting plastics are superior to thermoplastics in some applications.

Fakuma is also witnessing another trend of the plastics industry: In particular where plastics processing is involved, recycling is in great demand. Even high-tech materials like CFRP are being recycled more and more frequently and reused for new purposes.

The prevention of so-called “downcycling” by means of modern processes and recycling of materials sorted according to type is important in this respect.

“The plastics industry has been becoming more and more sustainable for a number of years already,” says Fakuma project manager Annemarie Schur.

This not only applies to the recycling of materials, but also to energy-saving and thus more economical manufacturing processes, energy-efficient machines and biodegradable plastics as well.

Moreover, the sustainable alternatives are in no way inferior to their conventional predecessors with regard to durability, processability and weight.

Injection moulding permits extensive component complexity

Fakuma sees itself as the number-one technical event for injection moulding. Numerous technology leaders from this sector will be on the scene at the trade show.

The injection moulders with their flexible options and ever more efficient processes are clearly in the majority as compared to 3D printing, foaming, extruding and thermoforming. “There’s no getting around injection moulding if you want to combine lightweight design and highly complex components,” states Annemarie Schur

For years, she’s been observing an upward trend in the number of innovation drivers, users and experts from this field of technology who are showing up in Friedrichshafen.

The show with continuously growing international recognition is taken advantage of by numerous exhibitors, who come here to unveil their new products to a broad-based audience for the first time. rs Demand plastics Fakuma plastics processing