Green hydrogen – Textiles recycling 14-04-2023 - Arhive

Green hydrogen – Textiles recycling

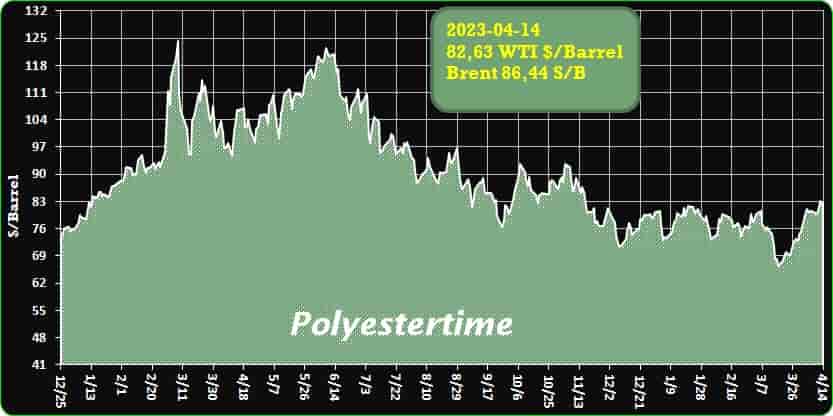

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Kolon Industries to make 100% plant-based eco-friendly plastic

Kolon Industries Inc.’s Future Technology Institute announced on Wednesday that it has partnered with Stora Enso Oyj, a global biomaterials leader from Finland, to develop eco-friendly plastics, said Kedglobal.

Stora Enso is a renowned manufacturer of biocomposite products and packaging with the technology to convert plant-based raw materials into chemical raw materials for plastics.

The two companies will focus on creating polyethylene furanoate (PEF) products, which are next-generation bioplastics. Leveraging Kolon Industries’ polymer plastics manufacturing and processing technology and Stora Enso’s raw material development capabilities, they aim to produce 100% natural and environmentally friendly plastic.

PEF is made from plant-based raw materials and boasts superior hardness, heat resistance and gas barrier properties compared to polyethylene terephthalate (PET), a common petrochemical plastic. It has the potential to replace existing beverage bottles and food packaging. Green hydrogen – Textiles recycling

Kolon plans to streamline the commercialization of PEF by optimizing the raw material supply chain. Upon mass production, it is expected to reduce carbon emissions by over 50% in comparison to existing PET.

“Through this agreement, we are building a stronger foundation for the bioplastic ecosystem. We will continue to expand the development of technologies for resource recycling,” said Han Sung-soo, head of the Future Technology Institute at Kolon Industries.

-Pyrum To Recycle Used Tyres From Mercedes – Benz In Future

Pyrum produces pyrolysis oil from the end-of-life tyres (ELTs) using its own innovative process

- Pyrum will recycle several hundred tonnes of used tyres from the Mercedes-Benz Used Parts Centre every year.

- The company produces pyrolysis oil from the ELTs using its own innovative process.

- Oil is used as a raw material in combination with biomethane in the production of virgin plastics for the manufacture of Mercedes-Benz vehicle components.

Pyrum Innovations AG, a pioneer in the sustainable recycling of end-of-life tyres (ELTs) based on its patented pyrolysis technology, is taking the next step in its cooperation with Mercedes-Benz AG.

In future, the company will recycle several hundred tonnes of used tyres from the Mercedes-Benz Used Parts Centre every year. The company produces pyrolysis oil from the ELTs using its own innovative process. Green hydrogen – Textiles recycling

The pyrolysis oil produced is then supplied to the cooperation partner BASF SE, which uses the oil as a raw material in combination with biomethane in the production of virgin plastics for the manufacture of Mercedes-Benz vehicle components.

Pascal Klein, CEO of Pyrum Innovations AG: “We are very pleased to take the next step in our cooperation with Mercedes-Benz. Through the chemical recycling of end-of-life tyres from Mercedes-Benz vehicles, we can jointly reduce the use of fossil resources and ultimately close material cycles.”

The used tyres are delivered from the Mercedes-Benz Used Parts Centre and disposed of at Pyrum’s main plant in Dillingen. Pyrum has already been supplying pyrolysis oil to BASF since last year.

BASF then feeds this into its Verbund together with biomethane from agricultural waste at the start of production and uses it to produce a virgin plastic that is certified according to the so-called “mass balance process”.

Since last year, the first series-production models such as the EQE and the Mercedes-Benz S-Class have been equipped with door handles.

Furthermore, the Mercedes-Benz S-Class will receive a crash absorber made from the recycled plastic material. Green hydrogen – Textiles recycling

-EC greenlights state aid for 100-MW Polish green hydrogen project

EC greenlights state aid for 100-MW Polish green hydrogen project Source: PKN Orlen

The European Commission on Wednesday approved the provision of EUR 158 million (USD 172.6m) in state aid to Polish oil refiner PKN Orlen SA (WSE:PKN) for a 100-MW renewable hydrogen project.

PKN Orlen’s special purpose vehicle LOTOS Green H2 sp. z o.o will get a direct grant of the abovementioned amount to install an electrolyser system for green hydrogen production along with a 50-MW solar power plant with 20 MWh of battery storage.

The EC has cleared the project under the Guidelines on State aid for climate, environmental protection and energy 2022 (CEEAG) rather than as part of the IPCEI programme. It has been determined that the measure has an incentive effect and limited impact on competition and trade within the EU, and comes with sufficient safeguards.

The electrolyser is seen to begin operation in 2027 and gradually ramp up its production to 13,600 tonnes of hydrogen per year. Green hydrogen – Textiles recycling

-Novolen technology expands portfolio for enhancing recycled polymers

Lummus Technology, a global provider of process technologies and value-driven energy solutions, announced the addition of Novolen Enhance performance polypropylene (PP) polymers, a family of products that enhance the properties of recycled polymers, said Hydrocarbonprocessing.

The new products are an expansion of Novolen’s PP portfolio and are specially designed to reduce carbon footprints while providing excellent material performance in blends with recycled polymers from post-industrial or post-consumer waste.

“With the new line of Enhance polymers, Lummus can deliver more innovative solutions for a circular economy,” said Leon de Bruyn, President and Chief Executive Officer, Lummus Technology. “These products enable brand owners to create more sustainable products with reduced carbon emissions and outstanding material properties. From injection molding, thermoforming, to film and textile applications, Enhance polymers significantly expand the range of possible applications of recycled polymers, increasing their commercial value.” Green hydrogen – Textiles recycling

Using Enhance performance polymers in combination with recycled polymers, carbon footprint can be reduced by more than 40 percent compared to fully virgin materials, while achieving virgin-like material performance. This enables customers to achieve demanding sustainability targets while maintaining high product quality and customer satisfaction.

Enhance polymers combine tailored molecular weight characteristics with an outstanding physical property profile due to Novolen’s catalyst and process technology. When blended with recycled polymers, Enhance polymers significantly boost stiffness while preserving impact resistance. The polymers are suitable for combining with a wide range of recycled polymers, including post-consumer and post-industrial waste, and all types of polypropylenes such as homopolymers, random copolymers or impact copolymers.

-Alternative materials company Zeroplast acquired by Greiner

Zeroplast, founded in Austria in 2017 with the aim of developing alternatives suitable for everyday use to commonly used plastics, has been acquired by Greiner Innoventures, the innovation arm of plastics and foam expert Greiner, the companies have announced. The company has been renamed Greiner Zeroplast.

Based in Kremsmünster in Austria, Greiner Innoventures works with startups as a corporate business angel, looking for and researching new ideas and identifying future-oriented, innovative techniques and technologies. In doing so, the company lays a foundation for the continuity of Greiner, with investments and strategic decisions designed to ensure Greiner’s access to technology that will allow Greiner to keep pace with developments in the industry. Green hydrogen – Textiles recycling

“With our new subsidiary Greiner Zeroplast, we are hoping to open up new opportunities in the field of alternative plastics,” said Hannes Möseneder, managing director of Greiner Innoventures.

“We believe that nothing should be off limits when it comes to innovation. Greiner has been around for more than 150 years, and it all began with hand-made corks for bottles. If history has taught us anything, it’s that radical innovations are sometimes necessary if we are to continue to be successful in the future,” added Axel Kühner, CEO of Greiner AG.

Zeroplast has created an injection-mouldable material that is both sustainable and circular. As Greiner Zeroplast, further work will be directed at transitioning this to a commercial product.

When it started its development work, the company emphasised it was not aiming to redesign conventional plastic packaging to make it greener, lighter, better, more efficient or recyclable. Zeroplast had a far more radical goal: to create alternative bio-based compounds and packaging solutions that were plastic free and in no way competed with animal feed or food production. Furthermore, these compounds were to be processable on conventional equipment. Green hydrogen – Textiles recycling

-Textiles recycling: the sorting challenge

Until now, only a tiny fraction of discarded textiles is recycled.

While the clothing industry has doubled production in the past 15 years, the time garments are worn has fallen by more than 30%. At the same time, the rising demand for low-cost fast fashion is driving a decline in the quality of the materials, which makes them more difficult to re-use or recycle. According to the Ellen MacArthur Foundation, it is estimated that 114 million tonnes of textile waste are generated every year. Of the clothing that is collected for recycling, 12% is downcycled into lower-value applications such as insulation material, and less than 1% is used to make new clothing in a closed-loop circular economy. The high content of polyester in fast fashion also means that an increasing quantity of discarded textiles are incinerated in waste-to-energy plants because of its high calorific value. Green hydrogen – Textiles recycling

The environmental impact of textile waste

The rising consumption of clothing, coupled with the decreasing wearing time and increasing use of synthetic materials such as polyester and nylon, is worsening the negative impact on the environment. Large quantities of plastic microfibres shed through the washing of textiles are leaked into the ocean, accounting for 35% of microplastic pollution. Improper disposal can also result in flat textiles released into the environment, endangering wildlife on land and marine life.

Regulatory drive for the development of textile recycling

Policymakers have a key role to play in driving an increase in recycling. In Europe, in 2022 the Commission presented an EU Strategy for Sustainable Textiles, which includes extending the lifetime of textiles by recycling the materials they contain into new quality products. The revised Waste Framework Directive requires EU member countries to establish systems for separate collection of textile waste by the beginning of 2025, and at the same time, new collection and recycling targets will kick in. The infrastructure for collecting, sorting, and recycling these materials will need to expand fast in readiness for the new regulations.

The textile sorting challenge

Clothing is made of different fabrics, fixtures and accessories, such as buttons or zips, and they contain a variety of raw materials – combinations of natural and synthetic fibres, plastics, and metals. This makes disposing of it sustainably a complicated matter.

“The recycling industry requires pure fractions or very specific mixtures,” explains Annika Ludes, Engineer for Digital Solutions at Stadler. “This means removing the fixtures and accessories from the fabric. The different materials in the garment – the outside fabric, the lining, the seams – need to be separated, then the different fibres in each fabric (cotton, elastane, polyester, etc.) must be sorted.” Green hydrogen – Textiles recycling

Today, textile sorting is done manually, and only a small portion of the output material is suitable for recycling. However, research is ongoing on automating the process with the aim of producing the high-quality fractions required to address the recycling challenge.

-Potential of carbon and silicon nonwovens

New electrospun nonwovens exhibiting an unusual combination of high electrical conductivity and extremely low thermal conductivity have been developed in Germany.

They represent a breakthrough in materials research since it has been possible to decouple electrical and thermal conductivity based on a simple-to-implement material concept. The nonwovens are made of carbon and silicon-based ceramic via the electrospinning process and are attractive for technological applications, such as in energy technology and electronics. They can be manufactured and processed cost-effectively on an industrial scale. Green hydrogen – Textiles recycling

Normally, high electrical conductivity is associated with high thermal conductivity, and low thermal conductivity goes with low electrical conductivity. However, in many high-tech industries, there is growing interest in multifunctional materials that combine good electric with low thermal transport. Though several strategies for achieving this have been developed – such as dense inorganic materials, conjugated polymers and alloys – it is still a major challenge in flexible, foldable materials.

![]()