Bio-Based Polyester – Recycled PVC 13-04-2023 - Arhive

Bio-Based Polyester – Recycled PVC

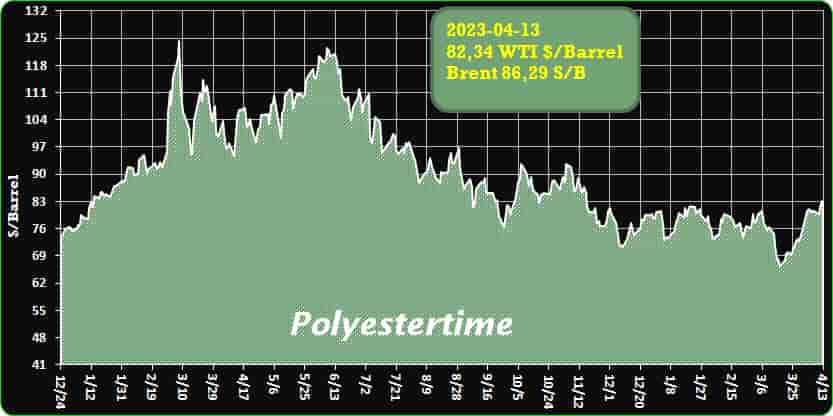

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

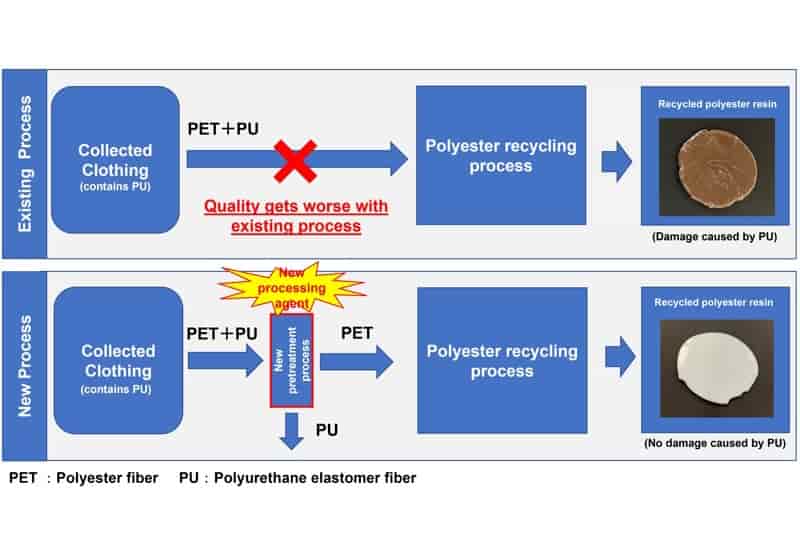

-Teijin Frontier develops technology to remove PU elastomer fibre from discarded polyester apparel

Polyurethane (PU) elastomer fibre has been removed from discarded polyester clothing using a new foreign material removal technique, according to Teijin Frontier Co., Ltd., a company that converts fibres and products for the Teijin Group.

The method incorporates a new processing agent that is applied during the chemical recycling process’ pretreatment stage and helps raise the calibre of the recycled polyester fibre produced from clothes made with PU elastomer fibre.

The new technology also helps to avoid the decolourisation of polyester fibre and gets rid of extraneous substances like dyes in addition to eliminating the PU elastomer fibre. Since October 2022, Teijin Frontier has been testing this revolutionary technology for actual application. Bio-Based Polyester – Recycled PVC

Teijin Frontier is working to develop cutting-edge technologies that enable recycling and increase the value of environmentally friendly materials, all while being guided by the THINK ECO® environmental approach.

The company is collaborating with the supply chain to create a full ecosystem spanning clothes collection, sorting, and recycling as part of its programme centred on polyester fibre. Teijin Frontier is optimistic that its novel approach to removing foreign materials will assist broaden the use of fiber-to-fiber recycling and further the goal of a society with zero waste.

The PU elastomer fibre swells with the new foreign material removal technique which breaks the chemical linkages, and the new processing agent dissolves them.

To maximise decolourisation of the polyester fibre, the agent simultaneously removes unwanted contaminants, including colours. The processing agent can be collected and reused to reduce environmental burden and system costs. By using this technique, recycled polyester materials can be produced that can be recycled chemically.

With the rise in popularity of casual wear, quick-drying, wrinkle-resistant, and comfortable clothes, stretchable polyester clothing containing PU elastomer fibre is becoming more and more common. Bio-Based Polyester – Recycled PVC

-Plastic recycling volumes increase in 2021

Despite the overall increase compared with 2020, recovery of HDPE bottles and PP declined.

Plastic recycling volumes in the U.S. increased by 280.3 million pounds in 2021 compared with the previous year, with recyclers acquiring more than 5 billion pounds of postconsumer plastic for recycling, according to the “2021 U.S. Post-consumer Plastic Recycling Data Report.”

The report, prepared by Stina Inc., Sonoma, California, based on surveys conducted by that company and the National Association for PET Container Resources (NAPCOR), Charlotte, North Carolina, was released by the Association of Plastic Recyclers (APR), The Institute of Scrap Recycling Industries (ISRI), both based in Washington, and the U.S. Plastics Pact, Walpole, New Hampshire, and funded in part by The Recycling Partnership, Washington. Bio-Based Polyester – Recycled PVC

All major categories of plastic recovered for recycling had a net increase in total pounds reported in 2021 compared with 2020, specifically bottles, nonbottle rigids and film, according to the report. Within those broader categories, however, declines were seen for high-density polyethylene (HDPE) bottles and polypropylene (PP) recovery.

-Filtration technology that is up to the task

Contamination is what Fimic’s filters are built to handle

As demand for recycled PET rises, brands are turning to waste sources that would previously not have been considered. To keep pace with this development, Fimic has steadily worked to create new filter solutions that can handle the challenges posed by these more contaminated PET waste streams.

Polyethylene terephthalate, more commonly simply called PET, is widely used world-wide in many different applications. Light, strong, durable and safe, PET offers a number of advantages over other commonly used plastics. Its performance and recyclability make it one of the more sustainable choices among packaging materials. PET, both virgin and recycled, is food-contact approved throughout the EU, as well as many other countries, although its applications go far beyond food packaging alone.

PET is a popular choice in sectors that run the gamut from the beverage, pharmaceutical and medical industries to clothing and the automotive branch.

70% of carbonated soft drinks, fruit juices, dilutable drinks and bottled water containers are made from PET. Bio-Based Polyester – Recycled PVC

PET can be recycled nearly infinitely, and because it can be reprocessed into new, high-quality products, it also lowers the need for virgin PET. The carbon footprint of recycled PET products is up to 90% smaller than conventionally produced products from virgin PET. PET, therefore is an import enabler of the circular economy.

Feedstock competition

There is, however, another side to PET’s success story. Over the past few years, increasingly, major brands – traditionally heavy users of PET packaging – are being held accountable for the carbon footprints of their products and operations. Mitigating actions, like packaging redesign and light-weighting, have been implemented by many, aimed at driving down their virgin plastics consumption and increasing reusability. Minimum targets for the use of recycled content have been set. The implementation of these and other measures has been fuelled by the looming new regulations and taxes on packaging , single use and otherwise – in the EU and elsewhere. The result has been an increasingly heated competition for available rPET. Bio-Based Polyester – Recycled PVC

New capacity

Rising rPET demand and prices are incentivising investments in new recycling capacity. Europe has seen a 21% increase in the installed capacity for PET recycling, according to a report by Plastics Recyclers Europe, PETCORE Europe, Natural Mineral Water Europe (NMWE), and UNESDA Soft Drinks Europe. At the same time global rPET capacity is forecast to boom over the next five years.

This ‘run’ on rPET has led producers of PET packaging products – both food contact and non-food contact applications – to look for new feedstock sources, instead of relying on hot-washed bottle flakes only. This has, inevitably, led to the use of more contaminated PET waste streams. Bio-Based Polyester – Recycled PVC

-Fashion & Retail News: Brands Put Bio-Based Polyester to the Test

The bio-based polyester is made from renewable s and has a lower carbon footprint compared to traditional polyester

Fashion & Retail News: Brands Put Bio-Based Polyester to the Test

News Highlight’s:

- The article discusses the road-testing of bio-based polyester by various brands in the fashion and retail industry

- The bio-based polyester is made from renewable s and has a lower carbon footprint compared to traditional polyester

- Companies like H&M, Nike, and Stella McCartney have incorporated this material in their products and are promoting sustainable fashion

The article discusses the road-testing of bio-based polyester by various brands in the fashion and retail industry. The bio-based polyester is made from renewable s and has a lower carbon footprint compared to traditional polyester. Bio-Based Polyester – Recycled PVC

Companies like H&M, Nike, and Stella McCartney have incorporated this material in their products and are promoting sustainable fashion. The article also mentions the challenges faced by the industry in terms of scaling up production and reducing costs. The use of bio-based materials in fashion is seen as a step towards a more sustainable future and reducing the environmental impact of the industry.

Brands road-test bio-based polyester is the latest news in the fashion and retail industry. This new development is expected to revolutionize the way we produce textile products. The use of bio-based polyester in the fashion industry is a step towards sustainability, and it is a significant milestone in the industry’s efforts to reduce its environmental impact. Bio-Based Polyester – Recycled PVC

The fashion industry has been under scrutiny for its environmental impact, and many sustainable fashion initiatives have been launched.

-Teknor Apex Buys Compounder of Recycled PVC

Article-Teknor Apex Buys Compounder of Recycled PVC

Custom plastics compounder Teknor Apex reported today that it acquired the business of Nu-Pro Polymers Inc. late last year. Based in Wheeling, IL, Nu-Pro converts clean post-industrial (PIR) streams into new PVC compounds that the company claims are equivalent in performance to prime materials.

Nu-Pro specializes in clear, natural, and black reprocessed compounds in a range of durometers, said Teknor Apex in the announcement. Under the acquisition, Nu-Pro will continue to produce products for Teknor Apex at this time under the Cycle-Tek brand as a subsidiary of Teknor Apex. Bio-Based Polyester – Recycled PVC

The terms of the transaction were not disclosed.

“We are very excited about this acquisition that will further enable us to develop innovative compounds that meet the performance and sustainability requirements of our customers,” said Teknor Apex Executive Vice President Lou Cappucci.

“Our flexible, reprocessed, and recycled PVC compounds incorporate up to 90% post-industrial recycled content.” said Don Brown, co-owner of Nu-Pro Polymers.

“Our goal is to convert PVC waste streams into products that perform for our customers.”

“Teknor Apex prides itself on providing innovative and sustainable products, whether through development, expansion, or partnerships,” commented Sunny Mahajan, Sr., technical manager at Teknor Apex and serving as business manager for Cycle-Tek.

-Lotus Teknik starts up biodegradable wipes line

Turkey’s Lotus Teknik Tekstil, has successfully started up a complete line to produce nonwoven roll goods for biodegradable, plastic-free wet wipes. This line has been delivered, installed, and commissioned by international technology group Andritz.

The state-of-the-art neXline wetlace CP line combines the benefits of two technologies: wetlaid and spunlace with natural fibres processed gently to create a high-performance and sustainable wipe. Bio-Based Polyester – Recycled PVC

This next-generation wipe, called Newipe, combines the benefits of spunlace fabric, in particular remarkable strength in all directions, with the biodegradability and softness of a Wetlace fabric. It is produced with a lower carbon footprint, has a low lint rate, and does not generate dust during production.

Andritz and Lotus Teknik Tekstil have a strong focus on sustainable products for a greener future. Lotus Teknik Tekstil supported the technology development intensively from the perspective of a roll goods producer and converter. Therefore, the nonwoven roll goods perfectly suit the converting lines for wipes.

Ceyhun Zincirkiran, co-owner and managing director of Lotus Teknik Tekstil A.Ş., said: “We aim to be a part of the sustainable transformation. That’s why we have developed the Newipe next-generation viscose fabric. With the neXline wetlace CP line from Andritz we are setting new benchmarks on the market and securing our position as one of the industry leaders in wipes production.” Bio-Based Polyester – Recycled PVC

Lotus Teknik Tekstil A.Ş. is a major nonwoven roll good producer and a member of a group company. The group company consists of four companies that operate end-to-end manufacturing including nonwovens, cardboard packings, plastics, and finished wet wipe products.

-DSM completes sale of Engineering Materials business

Royal DSM, a global purpose-led science-based company, announces the completion of the sale of its Engineering Materials business to Advent International and LANXESS for an Enterprise Value of EUR3.85 billion, said the company.

The agreement was initially announced on 31 May 2022. The transaction covers all of DSM’s Engineering Materials activities and marks the conclusion of DSM’s divestment of its Materials businesses in order to focus on Health and Nutrition. DSM anticipates a book profit on the sale of Engineering Materials of around EUR2.7 billion. DSM will receive approximately EUR3.5 billion net in cash. Bio-Based Polyester – Recycled PV

We remind, Versalis, Eni’s chemical company, has acquired the technology to produce enzymes for second-generation ethanol from DSM. The agreement has a strategic value for Versalis as it integrates with proprietary Proesa® technology, applied at the Crescentino plant for the production of sustainable bioethanol and chemical products from lignocellulosic biomass, improving the competitiveness of technology and production.