Partial relief for man made yarn processing – India Man made yarn processing - Arhive

India Man made yarn processing India Man made yarn processing India Man made yarn processing

Partial relief for man made yarn processing

The job work on texurising, twisting, weaving, yarn dyeing have been reduced to 5% from 18 %

Rajesh Bhayani | Mumbai

In Tatters: Mechanisation is a problem but demonetisation has added to weavers’ woes here, say experts

In a partial relief for man-made textile units, the rate of goods and services tax (GST) on texurising, twisting, weaving and yarn-dyeing has been reduced from 18 per cent to 5 per cent.

In a partial relief for man-made textile units, the rate of goods and services tax (GST) on texurising, twisting, weaving and yarn-dyeing has been reduced from 18 per cent to 5 per cent.

Although the industry has welcomed the rate reduction, a senior industry representative said that, despite relief, several looms and fabric makers will still have unutilised credit on their books, raising the cost of fabric by 8-10 per cent.

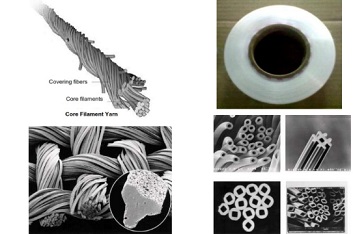

An industry official said that Partially Oriented Yarn (POY), Polyester Filament Yarn (PFY) and Staple Fibre manufactured by virgin chips/granules are covered under the umbrella of “man-made fibres” and liable to be taxed at 18% under GST.

But other processes of textile yarn units, such as twisting, warping, doubling, dyeing, printing, bleaching, mercerising, texturing, multi-folding, cabeling, air mingiling, air-texturising, sizing, etc, are not covered under the umbrella of “man-made fibres”. The job work rate of such processes at textile yarn units falls under the 5 per cent GST slap.

This is a relief for certain processes and works beyond chips will get this benefit. Huge credit will remain unused as the duty on fabric is 5 per cent; the cost of fabric will increase by 8-10 per cent, a senior synthetic yarn industry official said.

Merchant exporters who make garments and buy fabric or do all the processes outside will also suffer as the duty refund will have to bear the burden of unutilised credit, he added. They will be at a disadvantageous position as compared to composite mills that do all processes in-house.