Nonwovens – Enzymes recycling 21-04-2023 - Arhive

Nonwovens – Enzymes recycling

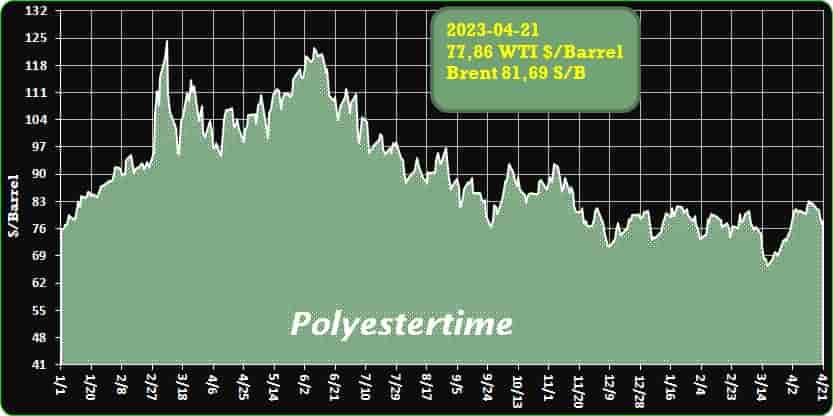

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-PFNonwovens reduce carbon footprint using Borealis Bornewables polymers

Sustainable personal hygiene fabrics offer a significantly better environmental profile

PFNonwovens, a leading player in the global hygiene market, has announced that it has opted to use Borealis’ Bornewables PP resins for the production of its nonwoven materials for the personal hygiene market.

Demographic developments – population growth, aging – are resulting in rising demand for absorbent products in everyday personal hygiene, from baby diapers to feminine hygiene products and incontinence care.

PFN has teamed up with Borealis to use that company’s more sustainable PP resins for the spunbond and meltblown solutions it delivers.

“Anticipating the growing demand for more sustainable nonwoven solutions, we have focused our development resources over the past several years on the circular sphere to accelerate our journey towards climate neutrality,” explains Tonny De Beer, Chief Product, Technology & Sustainability Officer at PFNonwovens Group.

“For PFN’s nonwoven products, fossil-based resins are today the main contributor to the carbon footprint. Therefore, using the Borealis Bornewables instead of standard fossil-based resins will significantly reduce the carbon footprint, even enabling products with a carbon footprint under zero.” Nonwovens – Enzymes recycling

The portfolio of Bornewables consists of direct drop-in replacement materials manufactured with second-generation renewable feedstock derived solely from waste and residue streams, for example, from vegetable oil production, the paper and pulp industry or used cooking oil.

The renewable content in all Bornewables products is mass balance accredited under the ISCC Plus certification standard. This means these waste and residue streams are traceable back to their point of origin, following the ISCC Plus chain of custody, confirming their authenticity. The resins offer a reduced carbon footprint, enabling Borealis’ customers to meet their sustainability targets while maintaining existing quality standards. For PFN this means that for every tonne of certified Bornewables PP used in production, a maximum equivalent amount of nonwoven material can be claimed as certified renewable. And as drop-ins, no adjustments are required to be made to the existing manufacturing process Nonwovens – Enzymes recycling

-Veocel expands responsible viscose portfolio

Lenzing Group, the global producer of wood-based speciality fibres, has announced the expansion of its sustainable viscose fibre portfolio globally with the launch of carbon neutral Veocel branded viscose fibres for Europe and the US.

In Asia, meanwhile, Lenzing will convert the existing production capacity for conventional viscose into capacity for responsible speciality fibres in the second half of this year. The expansion represents Veocel’s latest act in providing nonwovens value chain partners and brands with offerings that make a positive impact on the environment and empower an industry-wide shift to reduce carbon footprints. Nonwovens – Enzymes recycling

“Everything we do is centered around Veocel’s mission to be a responsible everyday care brand and demonstrate our care for the future of our planet,” said said Monique Buch, vice president, Global Nonwovens Business, Lenzing. “We believe it is imperative for us to not only reduce our own carbon emissions, but also to empower our partners to reduce their carbon footprint. The launch of our carbon neutral Veocel Viscose fibres via our production plant in Austria and the investment in converting our production plant in Asia to production of environmentally responsible viscose, highlights our commitment to ongoing innovation and driving positive environmental impact. We hope that by taking responsibility to effect real change within the industry, we can build a better tomorrow for future generations.”

For the carbon neutral Veocel Viscose fibres Lenzing has partnered with ClimatePartner, a leading solution provider for corporate climate action. The fibers are made from wood and pulp sources derived from sustainably and responsibly managed forests, following the stringent guidelines of the Lenzing Wood and Pulp Policy and trusted forest certification systems. Nonwovens – Enzymes recycling

-Plastics recycling rebounds from pandemic lows

The U.S. plastic bottle recycling rate was 28.2% in 2021, up 1 percentage point from a year earlier, according to an industry report released April 11.

The increase in the bottle recycling rate was driven by PET bottles, the data shows. The country recycled about 28.7% of PET bottles in 2021, up 1.6 percentage points from 2020. The HDPE bottle recycling rate was 28.9%, which was roughly flat from the year before.

PP and other polymers made up an extremely small percentage of other containers.

The report was released today by the Association of Plastic Recyclers (APR), the Institute of Scrap Recycling Industries (ISRI) and the U.S. Plastics Pact.

The Recycling Partnership also contributed funding to the research, which was conducted by Stina Inc. using surveys conducted by Stina and the National Association for PET Container Resources (NAPCOR). Nonwovens – Enzymes recycling

In addition to recycling rates, the study shows an overall increase in weights of plastic recovered in 2021, reflecting a bounceback from the pandemic dip in 2020.

In 2021, 5.08 billion pounds total were recovered for recycling, up 5.8% from the year before. That weight includes bottles, non-bottle rigid plastics, film and other plastic, but it excludes foam.

“The 2021 rate report shows the strength of the recycling industry, as they face ongoing challenges including competition with low disposal costs, collection rates and virgin resin prices,” Steve Alexander, APR’s president and CEO, stated in a press release.

HDPE volume down

Within the total weight recycled, there was good news and bad news, however.

The weight of PET bottles recycled came in at 1.93 billion pounds, up 9.3% from the year before. But the weight of HDPE bottles recovered was 927 million pounds, down 1.7% from 2020. Nonwovens – Enzymes recycling

The analysis also showed that domestic reclaimers continue to handle the vast majority of post-consumer plastic recovered here. Overall across all categories, 92.3% of recovered plastic was purchased by domestic reclaimers, and 7.7% was exported in 2021. That breakdown is the result of a trend going back several years.

-PX hikes on the expectation of gasoline blending demand

PX price rallied again last week amid brisk trading. On Apr 14, a deal of Asia-origin May goods was concluded at $1165/mt and two deals of Asia-origin Jun goods done at $1147/mt CFR. PX price hiked to $1152/mt CFR on Apr 13, new high since Jul 8 2022, and was little changed on Apr 14.

In terms of feedstock, crude oil and naphtha fluctuated upward this week, supportive to PX price. Downstream PTA futures consolidated at highs with advancing momentum weakening, while polyester plant operating rate dropped.

In terms of plant operations, Weilian Chemical’s 1 million mt/yr PX line, CNPC Urumqi’s 1 million mt/yr plant and Taiwan FCFC’s one 950kt/yr plant were shut earlier as scheduled for turnarounds. In mid-week, it was said that there were some troubles in Fujia Dahua’s 2.6 million mt/yr reformer. Afterwards, the troubles were solved and its PX plant operation was not affected. Nonwovens – Enzymes recycling

There was not much advancing momentum from PX fundamentals, while the main support came from expectations for gasoline blending.

On Apr 11, South Korea announced the export data during Apr 1-10, during which it exported about 103.8kt of PX, new low compared to the same periods of past months this year. About 29kt of PX exports went to the US. Therefore, participants were concerned about tight PX supply in Asia.

-Enzymes enable infinite recycling

Australian Samsara Eco brings affordable circularity within reach

After taking part in an ideathon aimed at providing solutions for a plastics-free future, Paul Riley embarked on a year-long search for materials or technologies to solve this challenge. The answer he found ultimately resulted in a start-up called Samsara Eco.

In 2019, Paul Riley, an Australian businessman with experience in venture capital and private equity business building participated in a workshop with the CSIRO, a top research organisation in Australia; Woolworths Group, one of Australia’s biggest retail organisations; and several others on the topic of a plastics-free future. Nonwovens – Enzymes recycling

It was the start of a new direction for Riley, said Ellen Burtenshaw-Davies, Chief of Staff for Samsara Eco during a recent interview with Sustainable Plastics. According to Burtenshaw-Davies, Riley then spent the following year exploring possible options and examining various technologies and their potential readiness for commercialisation that addressed this issue. At a certain point, completely by chance, he came across an article about two chemistry PhD students at the Australian National University (ANU) in Canberra, who were working on the development of enzymes that could degrade plastic.

He contacted their supervisor and by December of 2020, Samsara Eco had been founded. The start-up, an initiative of Main Sequence (a venture capital fund founded by CSIRO, a federal government-backed research organization, to help commercialise research projects), the ANU, Woolworths Group and Paul Riley, launched with a team of just four people, including the two ANU students, Matthew Spence and Vanessa Vongsouthi, under the name Samsara. In Sanskrit, Samsara literally means ‘flowing around’ or ‘world’, in reference to the cycle of life, death, rebirth and redeath – a fitting designation for a company developing technology for ‘infinite recycling’. Nonwovens – Enzymes recycling

Fast forward

Over the next two years, the technology was further developed and expanded. The idea of using enzymes, said Burtenshaw-Davies, is quite obviously not new. Research teams – in the UK and Japan, for example – have also discovered enzymes able to degrade plastic; and they’ve been found in, among others, mushrooms, mealworms, and bacteria that degrade plastic – but, she explained, “none of those will really be able to be adapted for commercial scale recycling or degradation, because they evolved naturally.”

The scientists at Samsara Eco have found ways to optimise these enzymes and are now aiming to commercialise the technology at scale within the short term. They have created a proprietary algorithm to design new-to-nature enzymes specific for different types of plastics and specific for industrial processes that have a low carbon footprint, said Burtenshaw-Davies.

“And they have been designed to be very efficient, so we don’t need energy- or carbon-intensive preprocessing steps for the plastic that we recycle,” she said.

The first enzymes designed by Samsara were specifically targeted at PET/polyester and these have already been validated and patented. Currently, the company is working to expand its enzyme library further. Nonwovens – Enzymes recycling

“We will be announcing some new ones designed for plastics found in the packaging industry and in fashion and textiles, but also we are also looking beyond that, at other sectors, such as the automotive industry, as well,” said Burtenshaw-Davies.

-Multi-Colour Corporation’s shrink sleeves receive a common approval from RecyClass and EPBP

ollowing the partnership established in 2022 between European PET Bottle Platform (EPBP) and RecyClass, the first joint approval was issued to MultiColor Corporation (MCC) technologies – ‘RecycLABEL® Floatable SSL Flexo F779752’ & ‘RecycLABEL® Floatable SSL Gravure 40951’.

The tested technologies are printed shrink sleeves and the analysis consisted of evaluating the effects of inks and the shrinkage on the PET recycling process. The use of shrink sleeves eliminates the need for adhesives, which are among the main design for recycling concerns for PET bottles. Nonwovens – Enzymes recycling

Independent testing was carried out by Plastic Technologies Inc. (PTI), in line with the EPBP’s quick test procedures for bleeding inks1 and for separation by density2. Results show that the two technologies are fully compatible with the PET recycling stream in Europe, given that the coverage of the sleeves should not exceed 70% for bottles of 500 ml and above; and not more than 50% for bottles smaller than 500 ml3. The limitation tied to the size is important to safeguard the efficiency of the sorting of clear PET bottles.

-Maire Tecnimont Group awarded new technology and high-value engineering contracts

Maire Tecnimont S.p.A. announces that some of its Sustainable Technology Solutions subsidiaries, which are directly controlled by NextChem Holding, have been awarded several new contracts for technology licensing and engineering services for an overall value of approximately USD 90 million, said Hydrocarbonprocessing.

These contracts have been granted by international clients mainly in Europe and the Far East.

In particular, Stamicarbon, NextChem Holding innovation and licensing company engaged in nitrogen technologies, has been awarded licensing, process design package and equipment supply contracts for an Ultra-Low Energy grassroots urea plant in the Jiangxi province, China. Nonwovens – Enzymes recycling

This will be the largest Ultra-Low Energy plant with a design capacity of 3,850 metric tons per day and the seventh one globally based on Stamicarbon’s proprietary innovative design, which allows steam consumption to be reduced by about 35% and cooling water consumption by about 16% compared to traditional processes.

We remind, Maire Tecnimont S.p.A. announces that, through its subsidiary NextChem Holding S.p.A., it is expanding into the high-value derivates and biodegradable plastic by-products licensing markets with the acquisition of an 83,5% stake of Conser, a technology licensor and process engineering design company based in Rome, Italy.