Nylon-Derived-From-Tires – Bioplastics 11-02-2022 - Arhive

Nylon-Derived-From-Tires – Bioplastics

-BPF : Need to incorporate recycled content into your packaging?

The British Plastics Federation (BPF), in association with Plastics Europe, is set to hold a key seminar containing crucial guidance for packaging manufacturers or importers looking to incorporate recycled plastics into their products.

The session will contain crucial guidance for packaging manufacturers or importers looking to incorporate recycled plastics into their products.

With the UK government’s Plastic Packaging Tax set to take effect 1 April 2022, charged at a rate of £200 per tonne of non-compliant packaging manufactured or imported, the industry is bracing for the impact of the new charges.

Tim Chandler, Senior Policy Advisor, Food Contacts Material Food Additives, Food Standards Agency (FSA) will kick the half-day event off, answering attendees’ questions about legislative requirements for plastic and recycled plastic in food contact applications. Nylon-Derived-From-Tires – Bioplastics

William Guest, Sustainable Packaging Manager, Tesco, will explain the retail giant’s policies for incorporating recycled content, as well as food contact packaging from recycled content.

From a manufacturer’s perspective, Adam Bolsover, Quality and Technical Manager at St. Johns Packaging will present on what he thinks are the five biggest issues hindering recycled content, and will provide an insight into how these barriers can be overcome and what their impact will be.

Inna Knelsen, Senior Manager at the International Sustainability & Carbon Certification (ISCC), and Mireia Boada, Project Manager of Plastics Recyclers Europe, will provide an overview of progress with their respective organisations’ certification schemes. Nylon-Derived-From-Tires – Bioplastics

-Nylon Derived From Tires and Garden-inspired Capsules

Man-made textiles specialist Fulgar is marketing its most experimental innovation yet, aimed at establishing a cross-industry recycling standard.

Called O-Cycle, Fulgar’s new nylon 6.6 yarn is crafted from tire cord waste. It’s the result of a partnership with Germany-based public company Basf, which provided the technology to turn tires destined for landfill into brand new materials to be channeled into the apparel industry. Nylon-Derived-From-Tires – Bioplastics

All the Pieces from the Palace and Juergen Teller Capsule Collection

The repurposed nylon preserves the same features — such as resilience and elasticity, non-allergenic properties and resistance to mold, bacteria and insects — as virgin nylon. This is achieved thanks to the high-tech ChemCycling process, as part of which tires are broken down into their original components, such as coke, gas and pyrolysis oil, via a thermochemical procedure.

Each byproduct is recycled: as coke is returned to tire manufacturers, gas is employed into the thermolysis process itself and the oil is channeled into new apparel. Nylon-Derived-From-Tires – Bioplastics

“There are many recycled nylons 6 on the market, but this innovation represents the first of its kind when it comes to nylon 6.6,” said Fulgar head of marketing Alan Garosi.

The process presents quite a few challenges, including the collection of wasted tires, but it is opening up a new standard for potential cross-industry recycling methods.

“Together with Fulgar we’re entering the textile sector and it’s a milestone,” said Marina Favretto, key account manager at Basf. “Nylon 6.6 is already widespread in other industries, including engineering plastics, industrial productions, such as airbag manufacturing.” Nylon-Derived-From-Tires – Bioplastics

She noted that carbon dioxide emissions also benefit from the recycling process, as the new technology saves end-of-life tires from incineration and reuses the gas released as part of the process, thus containing the CO2 balance.

SCG Chemicals or SCGC launched “Circular PP,” a high-quality post-consumer recycled resin (PCR) manufactured from recycled feedstock under the advanced recycling technology, one of the solutions from SCG GREEN POLYMERTM. Circular PP has the equivalent properties of virgin plastic resins, suitable for producing eco-friendly food packaging. Nylon-Derived-From-Tires – Bioplastics

SCGC is equipped with environmentally friendly plastic innovation and expertise in material sciences to develop eco-friendly packaging together with partners and brand owners, in line with global green packaging market, which is constantly growing. In addition, it also partnered with Visy Packaging to develop the first ASEAN’s food packaging that has been certified “ISCC PLUS” throughout the whole supply chain.

Tanawong Areeratchakul, CEO and President of SCG Chemicals, revealed the progress of environmentally-friendly plastic innovation, “SCG Chemicals, or SCGC, is committed to developing chemical innovations based on the circular economy to meet the needs of business and the environment following the ESG (Environmental, Social, and Governance) guidelines, leveraging innovation and plastic recycling technologies under the brand ‘SCG GREEN POLYMERTM’.

SCGC has now developed Circular PP made from Recycled Feedstock using Advanced Recycling Technology, transforming post-consumer plastics that hard to recycle into recycled feedstock and then reintroducing them into high-quality post-consumer recycled resin (PCR) with comparable properties and qualities of virgin plastic resins, suitable for the production of eco-friendly food packaging. It is an ideal material for the food packaging industry, which requires environmentally responsible materials and responds to the growing demand for green packaging. Furthermore, the advanced recycling process can help minimize landfill waste and greenhouse gas emissions from waste incineration.” Nylon-Derived-From-Tires – Bioplastics

“SCGC is fully equipped with innovations and a team of material science professionals. We are collaborating with partners and brand owners worldwide to develop and deliver eco-friendly packaging built from SCGC’s high-quality post-consumer recycled resins to address the demands of the green packaging market and to ensure a sustainable environment,” said Tanawong.

Karan Tejasen, Chief Operating Officer Performance and Polymer Packaging Business of SCG Packaging, disclosed, “Visy Packaging (Thailand), a subsidiary of SCG Packaging, a manufacturer of innovative and high-quality food packaging certified by ISCC PLUS throughout the whole supply chain, has partnered with SCGC to manufacture high-quality post-consumer recycled resins Circular PP, which is also certified by ISCC PLUS throughout the whole supply chain.

-Self-cleaning bioplastics repel liquid and dirt

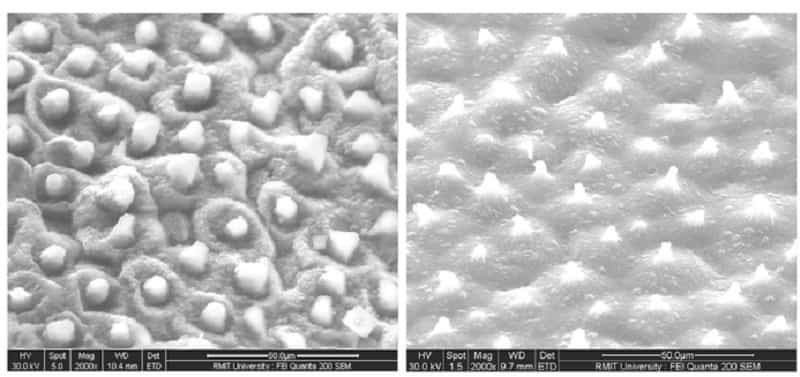

RMIT Ph.D. researcher Mehran Ghasemlou, lead author of the study published in Science of the Total Environment, said the new bioplastic was ideal for fresh food and takeaway packaging. Nylon-Derived-From-Tires – Bioplastics

“Plastic waste is one of our biggest environmental challenges but the alternatives we develop need to be both eco-friendly and cost-effective, to have a chance of widespread use,” Ghasemlou said.

“We designed this new bioplastic with large-scale fabrication in mind, ensuring it was simple to make and could easily be integrated with industrial manufacturing processes.”

Ghasemlou said nature was full of ingeniously-designed structures that could inspire researchers striving to develop new high-performance and multifunctional materials.

“We’ve replicated the phenomenally water-repellent structure of lotus leaves to deliver a unique type of bioplastic that precisely combines both strength and degradability,” he said. Nylon-Derived-From-Tires – Bioplastics

The bioplastic is made from cheap and widely-available raw materials—starch and cellulose—to keep production costs low and support rapid biodegradability.

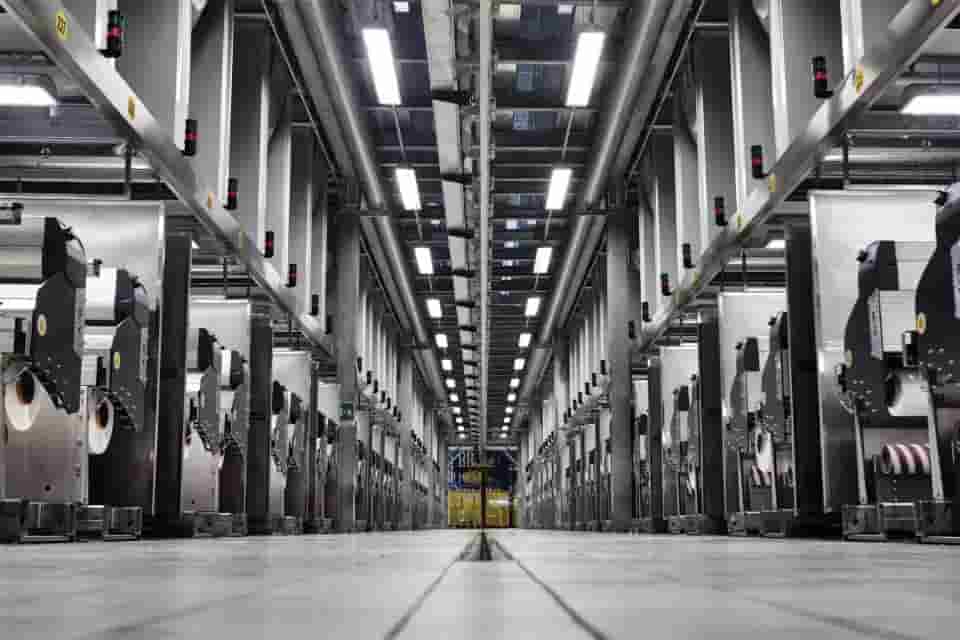

The fabrication process does not require heating or complicated equipment and would be simple to upscale to a roll-to-roll production line, Ghasemlou said.

Naturally compostable

While biodegradable plastics are a growing market, not all bioplastics are equal. Most biodegradable or compostable plastics require industrial processes and high temperatures to break them down.

The new bioplastic does not need industrial intervention to biodegrade, with trials showing it breaks down naturally and quickly in soil.

“There are big differences between plant-based materials—just because something is made from green ingredients doesn’t mean it will easily degrade,” Ghasemlou said.

“We carefully selected our raw materials for compostability and this is reflected in the results from our soil studies, where we can see our bioplastic rapidly breaks down simply with exposure to the bacteria and bugs in soil. Nylon-Derived-From-Tires – Bioplastics

-Japan’s Kaneka Expands Capacity for Biodegradable Polymer

The expansion will add 15,000 metric tons of annual production to the current 5,000

Tokyo-based Kaneka Corp. reports that it will increase production capacity of its biodegradable Green Planet polymer in Japan from the current 5,000 metric tons (MT) per year to 20,000 MT. It also plans to increase capacity in Europe and North America to satisfy rising demand. Nylon-Derived-From-Tires – Bioplastics

A law that goes into effect in Japan this April mandates a reduction in single-use plastics, a trend that is growing worldwide. Kaneka said that its Green Planet products hold promise as an innovative solution against the environmental harm caused by single-use plastics because they are compostable yet achieve the functionality of conventional plastics.

Green Planet is a polyhydroxyalkanoate-based biopolymer produced by microorganism biofermentation using plant oils, explained Kaneka. Green Planet resins and compounds break down in both soil and water at the end of life, depending on environmental conditions.

The company did not elaborate on the necessary conditions under which the material will decompose nor the time frame. Nylon-Derived-From-Tires – Bioplastics

Green Planet compounds currently are used to make straws, cutlery, coffee capsules, bags, films, and other products. These applications alone amount to more than 5 million tons per year, according to the company. It added that its Green Planet line has business potential on the order of hundreds of thousands of tons, and will be one of the core products in Kaneka’s business portfolio. Nylon-Derived-From-Tires – Bioplastics

-Repsol Augments Line of Low-Carbon Polypropylene Grades

The Repsol Reciclex range includes four new polymers for the automotive industry and three new circular polypropylene grades for non-food containers

Spain’s Repsol has introduced seven new polypropylene (PP) grades incorporating up to 80% recycled plastic content. These new low-carbon materials aim to provide solutions to meet the decarbonization commitments of the automotive sector and the circularity objectives of the packaging industry. Recycled plastic content for all grades has been verified under the UNE 15343 standard. Nylon-Derived-From-Tires – Bioplastics

The four new automotive materials incorporate up to 80% post-consumer recycled content in their formulation, while retaining the technical properties required for this application. The new grades are designed for vehicle lighting systems, hidden interior parts, and under-the-hood components with strict mechanical stress-resistance requirements Nylon-Derived-From-Tires – Bioplastics

In addition, in line with its commitment to the circular economy, another three PP injection grades have been added to the Repsol Reciclex range of non-food packaging, incorporating between 50% and 80% recycled plastic content.

These three new grades are especially suitable for household cleaning and drugstore product containers with chemical resistance requirements and paint containers with good mechanical resistance to enable stacking, among other properties.

Nylon-Derived-From-Tires – Bioplastics