Packaging-recycling – Plastic-additives 16-02-2022 - Arhive

Packaging-recycling – Plastic-additives

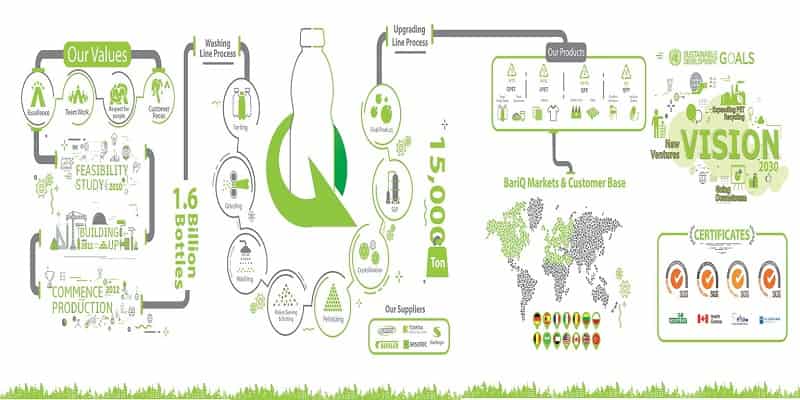

-BariQ for post-consumer PET recycling plans to invests EGP 400m this year

Mostafa Khairat, the CEO of BariQ for the recycling of post-consumer PET — affiliated to the Intro Holding Group — has revealed that the company plans to add two new production lines in the company’s factory, with investments amounting to EGP 400m. Khairat told Daily News Egypt on the side-lines of a conference held by …

Mostafa Khairat, the CEO of BariQ for the recycling of post-consumer PET — affiliated to the Intro Holding Group — has revealed that the company plans to add two new production lines in the company’s factory, with investments amounting to EGP 400m.

Khairat told Daily News Egypt on the side-lines of a conference held by the company to announce its expansions that investments will be pumped during the current year so that the factory will be ready before the United Nations’ Conference of Parties on Climate Change (COP 27), pointing out that the financing will be provided through international and local banks. Packaging-recycling – Plastic-additives

He explained that the financing will be through the European Bank for Reconstruction and Development, the British CDC, HSBC, and the Commercial International Bank, pointing out that local and international institutions are interested in financing green projects.

Khairat also pointed out that the recently added two lines in the company’s factory increased the maximum capacity from 30,000 tonnes to 60,000 tonnes annually, and that additional lines are expected to be added soon.

Furthermore, he stressed that financing through the issuance of green bonds is one of the company’s plans during the coming period. Packaging-recycling – Plastic-additives

-A closer look at CEFLEX’s next-generation flexible packaging recycling plant

CEFLEX recently launched plans for a next-generation recycling plant that it hopes will be complete by the end of 2023. This marks the creation of the first commercial waste processing site based around its Quality Recycling Process (QRP).

We spoke to project coordinator Graham Houlder about the prospects for new end market applications, a dedicated polypropylene stream, implications for chemical recycling and more. Packaging-recycling – Plastic-additives

First things first – could you introduce the new project and put it into context in terms of CEFLEX’s wider mission?

A circular economy needs the appropriate quality recycled content and – more importantly – a wide range of sustainable end markets to use it again and again. Improving mechanically recycled household flexible packaging is central to achieving this, which led us to look at getting the best possible quality recycled materials from sorting, washing, extrusion, and deodorization in detail. Along the way, we have developed lots of insights and established a four-step ‘Quality Recycling Process’ (QRP) recommendation. Packaging-recycling – Plastic-additives

If QRP’s four steps were all at the same plant, it could create a more efficient and steadier supply of circular materials for the marketplace. CELEX believes that having such a plant would also send a powerful economic current across the sector and incentivise greater collection for recycling of flexible packaging, providing even more recycled materials in the range of qualities different end markets demand.

For those not yet familiar with the details of QRP, what is it, and who developed it?

A dedicated action team of stakeholders from across the value chain defined our principal objectives for this process as: to increase volume, quality and value – delivering recycled flexible packaging materials to meet a wider range of end-market demand; and improve sorting and recycling, for the right quality outcome fit for purpose of any pathway.

Together, convertors, recyclers, material producers, and an EPR scheme have collaborated to run five semi-industrial trials harnessing new possibilities from existing technologies. During these trials we processed over 150 tons of flexible packaging post-consumer materials and produced “right quality” materials for further testing.

In the QRP project, several CEFLEX stakeholders have collaborated to produce pouches, shrink films and labels using PE and PP recyclates. As a breakthrough, the process also demonstrates that rPP from flexible packaging can be recycled into high-end film applications as with rPE. Packaging-recycling – Plastic-additives

Based on these trials and demonstrators, we conclude that the Quality Recycling Process offers a promising way to mechanically recycle a higher proportion of PE film and mixed Polyolefins (PO flexibles) bales than is currently possible or practiced today – with an emerging business case for investment in infrastructure to support it.

-Australia launches VinylCycle Label to recognise and reward use of recycled PVC

This week marks the launch of the new VinylCycle Label, representing a collaborative partnership between the Vinyl Council of Australia (VCA) and GECA to verify recycled PVC content claims, encourage uptake of recycled PVC and product design innovation. Packaging-recycling – Plastic-additives

Australia launches VinylCycle Label to recognise and reward use of recycled PVC

Australia launches VinylCycle Label to recognise and reward use of recycled PVC

The VCA, in conjunction with GECA and with consultation from VCA members and the broader PVC, or vinyl, industry, has developed ‘The Specifications for the Verification of Recycled PVC Content Claims in PVC Products’. The primary purpose of the specifications is to define criteria for the verification of products claiming to be made wholly or partially from recycled PVC or vinyl.

Claims shall consist of the manufacturer or distributor indicating the minimum percentage of recycled PVC content in a particular product range. VinylCycle is available to applicants claiming at least 10 per cent of the PVC compound (by weight) constitutes recycled PVC. Packaging-recycling – Plastic-additives

Vinyl Council CEO Sophi MacMillan said: “We are pleased to be able to work in collaboration with GECA to authenticate claims and we hope the label plays a role in supporting the Federal Government’s ReMade in Australia campaign through providing means for identification and recognition of products with PVC recyclate.”

To verify a VinylCycle claim, a GECA technical specialist checks all documentation to ensure credibility. GECA is widely respected and recognised in Australia and globally by green building schemes, including Green Star, LEED, IS Rating Scheme, theInternational WELL Building Institute, NABERS, and many procurement channels in government, education, hospitality, business, and the consumer sector.

– Andritz to exhibit at Inlegmash 2022

International technology group Andritz will be presenting its latest solutions for nonwovens production and textile manufacturing at Inlegmash 2022 in Moscow, Russia, which takes place from March 14 to 17 (booth 21F30).

Andritz notes that protecting the environment and conserving natural resources require new technologies. In the textile-related industries, the current challenge is to develop industrially and economically viable solutions to use eco-friendly fibres in nonwovens. Packaging-recycling – Plastic-additives

In this sector, Andritz is focusing on the airlay nonwoven application for hemp fibers (used in mattress production, insulation) and also geotextile end uses.

Andritz Laroche is a leading supplier of fibre processing technologies such as opening, blending, and dosing, airlay web forming, textile waste recycling, and decortication of bast fibers.

One focus of this product range lies on complete recycling lines for post-consumer and industrial textile waste to produce fibres for re-spinning and/or nonwoven end uses. At the show, Andritz will present recycling technologies for end-of-life textile products that can be used in multiple applications, such as automotive, insulation, mattresses, and furniture felts. Packaging-recycling – Plastic-additives

Customer awareness and regulations are pushing apparel brands to recycle their textile waste and use the recycled textile fibers in their own products. To support Andritz customers, a team with a high level of knowledge of the process is available to conduct customized trials at the company’s advanced technical center located at the Andritz Laroche facilities in Cours, France.

For the demanding Russian market for technologies based on bast fibres, Andritz will also present innovative products and the valorization of bast fibres, and with hemp in particular.

As a major player in the textile waste recycling sector Andritz Laroche offers airlay nonwoven technologies as well as bast fibre decortication and cottonizing lines.

-SPI strengthens its collaboration with Milliken to develop clear PP lid for food packaging

South Plastic Industry Co. Ltd., (or SPI) has leveraged its close, working relationship with additives supplier Milliken & Company to develop a clear, anti-fogging polypropylene (PP) lid for its microwaveable food packaging, according to SpecialChem. Packaging-recycling – Plastic-additives

Using Milliken’s Millad NX 8000 clarifier, the two parties have produced an UltraClear polypropylene (PP) resin that delivers on all the performance promises for ready-meal packaging, while also offering additional processing benefits. SPI also recently began using Milliken’s Hyperform HPN performance additives in its PP formulations, as well.

“By using Milliken’s additives, we are able to thermoform our products at a lower processing temperature, which allows us to reduce our energy use,” said Mr Tosho Wang, president of SPI. “At the same time,” he said, “these additives allow SPI to produce a thinner PP lid without affecting rigidity, which in turn helps to reduce plastic usage while increasing output.”

Saving energy during processing is a major plus for SPI, which runs dozens of thermoforming machines in its Taiwan plant. Packaging-recycling – Plastic-additives

The aim has been to replace oriented polystyrene (OPS) in this key application, but it wasn’t easy to find a way to get the highly recyclable PP to meet all the necessary performance requirements while also retaining the clarity and non-yellowing aesthetics that are vital to appealing to consumers on the grocery store shelves.

“Milliken’s additives produce an UltraClear PP that prevents yellowing, reduces oxidation reaction, and extends the shelf life of packaged product,” added Kua Cheng Huat, Milliken sales manager for Taiwan. But its crystal clarity is one of the most important features. Packaging-recycling – Plastic-additives

Technip Energies announced it has signed an agreement with Encina Development Group, LLC to deliver the Front-End Engineering Design (FEED) of the fluidized bed catalytic pyrolysis reaction section for Encina’s commercial plastic fluid catalytic cracking (PFCC) unit to produce circular chemicals from plastic waste in North America. Packaging-recycling – Plastic-additives

Encina utilizes a proprietary process to convert post-consumer scrap plastic to valuable circular chemical products. The process, called PFCC, converts mixed hard-to-recycle plastics into petrochemical feedstock such as light olefins and BTX aromatics. These circular feedstock chemicals can be seamlessly dropped into the fabrication process of new consumer products, reducing the need for virgin materials, and significantly reducing waste plastics.

This FEED will leverage Technip Energies’ industry credentials and know-how in fluidized design, established in the process technology FCC program. Technip Energies has an extensive portfolio of licensed and engineered FCC units, including more than 60 grassroots and 250 revamps, demonstrating its process and mechanical design experience. The company’s development team is committed to ongoing development initiatives in providing technology and engineering solutions to support the industry and its energy transition targets.

Bhaskar Patel, Senior Vice President Sustainable Fuels, Chemicals and Circularity, commented: “We are very pleased to be working with Encina on this first-ever commercial PFCC. Packaging-recycling – Plastic-additives

As the industry explores ways to reduce its environmental footprint, this project brings an important circular economy solution to petrochemicals, recycling plastic wastes to create feedstock.”

Packaging-recycling – Plastic-additives