Packaging-recycling -Plastics-circularity 02-12-2022 - Arhive

Packaging-recycling -Plastics-circularity

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Asia does not reach agreement on December contract prices of paraxylene

Negotiators to agree on December’s contract prices for paraxylene in Asia have failed to reach an agreement for this month, market sources toldICIS.

Sellers’ offers were at USD1,000-1,070 per tonne, CFR (cost and freight) Asia versus buyers’ offers at USD800-850 per tonne, CFR Asia.

This is the twelfth time this year that no agreement has been reached.

Earlierit was reported that the average capacity utilization at Chinese plants for the production of paraxylene remained stable in the week ended November 25, compared with the level of three weeks earlier. Thus, last week the load of paraxylene production in China was 78%. While in the week ended November 4, the average load of paraxylene plants in China increased by 7%. Packaging-recycling -Plastics-circularity

According to theSknaPlast review, the estimated consumption of PET in September of this year increased by 32% compared to a year earlier and amounted to 78.81 thousand tons. According to the results of the first nine months of this year, 621.61 thousand tons of PET were processed in Russia, which is 1% more than the same indicator in 2021.

-EU: Putting an end to wasteful packaging and boosting reuse and recycling

To address this continually expanding source of waste and consumer annoyance, the Commission has proposed new EU-wide rules on packaging.

On average, each European generates almost 180 kg of packaging waste per year. Packaging is one of the main users of virgin materials, as 40% of plastics and 50% of paper used in the EU are destined for packaging. Without action, the EU would see a further 19% increase in packaging waste by 2030, and for plastic packaging waste, even a 46% increase.

The new rules aim to stop this trend. For consumers, they will ensure reusable packaging options, eliminate unnecessary packaging, limit overpackaging, and provide clear labels to support correct recycling. For the industry, they will create new business opportunities, especially for smaller companies, decrease the need for virgin materials, boost Europe’s recycling capacity, and make Europe less dependent on primary resources and external suppliers. They will put the packaging sector on track for climate neutrality by 2050.

The Commission also brings clarity to consumers and industry on bio-based, compostable, and biodegradable plastics, setting out for which applications such plastics are truly environmentally beneficial and how they should be designed, disposed of, and recycled.

The proposals are crucial pieces of the Circular Economy Action Plan of the European Green Deal, which aims to standardize sustainable products. Additionally, they gave in to specific requests made by Europeans at the Conference on the Future of Europe.

Preventing packaging waste, boosting reuse and refill, and making all packaging recyclable by 2030 Packaging-recycling -Plastics-circularity

The proposed revision of the EU legislation on Packaging and Packaging Waste has three main objectives. First, to prevent the generation of packaging waste: reduce its quantity, restrict unnecessary packaging, and promote reusable and refillable packaging solutions. Second, to boost high quality (‘closed loop’) recycling: make all packaging on the EU market recyclable in an economically viable way by 2030. And finally, to reduce the need for primary natural resources and create a well-functioning market for secondary raw materials, increase the use of recycled plastics in packaging through mandatory targets.

The headline target is to reduce packaging waste by 15% by 2040 per Member State per capita, compared to 2018. This would lead to an overall waste reduction in the EU of some 37% compared to a scenario without changing the legislation. It will happen through both reuse and recycling.

To foster reuse or refill of packaging, which has declined steeply in the last 20 years, companies will have to offer a certain percentage of their products to consumers in reusable or refillable packaging, for example takeaway drinks and meals or e-commerce deliveries. There will also be some standardisation of packaging formats and clear labelling of reusable packaging.

To address clearly unnecessary packaging, certain forms of packaging will be banned, for example single-use packaging for food and beverages when consumed inside restaurants and cafés, single-use packaging for fruits and vegetables, miniature shampoo bottles, and other miniature packaging in hotels. Packaging-recycling -Plastics-circularity

Many measures aim to make packaging fully recyclable by 2030. This includes setting design criteria for packaging, creating mandatory deposit return systems for plastic bottles and aluminium cans, and making it clear which very limited types of packaging must be compostable so that consumers can throw these into biowaste.

There will also be mandatory rates of recycled content that producers have to include in new plastic packaging. This will help turn recycled plastic into a valuable raw material, as already shown by the example of PET bottles in the context of the Single-Use Plastics Directive.

The proposal will clear up any confusion over which packaging belongs in which recycling bin. Every piece of packaging will carry a label showing what the packaging is made of and into which waste stream it should go. Waste collection containers will carry the same labels. The same symbols will be used everywhere in the EU.

By 2030, the proposed measures would bring greenhouse gas emissions from packaging down to 43 million metric tons, compared to 66 million if the legislation is not changed—the reduction is about as much as the annual emissions of Croatia. Water use would be reduced by 1.1 million m3. The costs of environmental damage to the economy and society would be reduced by €6.4 billion relative to the baseline of 2030.

Single-use packaging industries will have to invest in a transition, but the overall economic and job creation impact in the EU is positive. Boosting reuse alone is expected to lead to more than 600,000 jobs in the reuse sector by 2030, many of them at local small and medium-sized companies. We expect much innovation in packaging solutions, making it convenient to reduce, reuse, and recycle. Measures are also expected to save money: each European could save almost €100 per year, if businesses pass on savings to consumers.

Clearing up confusion around bio-based, biodegradable, and compostable plastics

The use and production of bio-based, biodegradable, and compostable plastics have been steadily increasing. A number of conditions have to be met for these plastics to have positive environmental impacts, rather than exacerbating plastic pollution, climate change, and biodiversity loss. Packaging-recycling -Plastics-circularity

The Commission’s new framework clarifies in what way these plastics can be part of a sustainable future.

Biomass used to produce bio-based plastics must be sustainably sourced, with no harm to the environment and in respect of the ‘cascading use of biomass’ principle: producers should prioritise the use of organic waste and by-products as feedstock. In addition, to fight greenwashing and avoid misleading consumers, producers need to avoid generic claims on plastic products such as ‘bioplastic’ and ‘bio-based’. When communicating on bio-based content, producers should refer to the exact and measurable share of bio-based plastic content in the product (for example: ‘the product contains 50% bio-based plastic content’).

Biodegradable plastics must be approached with caution. They have their place in a sustainable future, but they need to be directed to specific applications where their environmental benefits and value for the circular economy are proven. Biodegradable plastics should by no means provide a licence to litter. Also, they must be labelled to show how long they will take to biodegrade, under what circumstances, and in what environment. Products that are likely to be littered, including those covered by the Single-Use Plastics Directive, cannot be claimed to be or labelled as biodegradable.

Industrially compostable plastics should only be used when they have environmental benefits, do not negatively affect the quality of the compost, and when there is a proper biowaste collection and treatment system in place. Industrially compostable packaging will only be allowed for tea bags, filter coffee pods and pads, fruit and vegetable stickers, and very light plastic bags. The products must always specify that they are certified for industrial composting, in line with EU standards.

Next steps

The proposal on packaging and packaging waste will now be considered by the European Parliament and the Council in the ordinary legislative procedure.

The policy framework on bio-based, biodegradable, and compostable plastics will guide future EU work on this issue, for example through ecodesign requirements for sustainable products, funding programs, and international discussions. The Commission encourages citizens, public authorities, and businesses to use this framework in their policy, investment, and purchasing decisions. Packaging-recycling -Plastics-circularity

Source: European Commission

-Honeywell and Environ intend to advance plastics circularity in Egypt through MOU

Honeywell has signed a Memorandum of Understanding (MoU) with Egypt’s Environ Adapt for Recycling Industries with the aim of advancing plastics recycling in the country.

The two organizations will explore the development of the first chemical recycling facility in Egypt that would be equipped with Honeywell’s advanced technology, capable of converting waste plastic into valuable recycled polymer feedstock (RPF).

Under the proposal outlined in the MoU, Honeywell UOP will work with Environ to deploy its latest UpCycle Process Technology – a technology that, when used in conjunction with other chemical and mechanical recycling processes, along with improvements to collection and sorting – has the potential to help recycle up to 90 percent of waste plastics. This represents a considerable increase in waste plastics that can be turned into polymer feedstock. Packaging-recycling -Plastics-circularity

“With a broad portfolio of ready now solutions that reduce waste, lower carbon emissions and support sustainable energy transition, Honeywell is well-positioned to support Middle Eastern and North African countries in their ESG goals,” said Khaled Hashem, president, Honeywell Egypt and North Africa. “Our Upcycle Process Technology represents an important milestone in the area of plastics circularity, and we are excited about the opportunity to collaborate with Environ to see how the technology could be deployed in Egypt in support of the country’s sustainability objectives.”

The MoU enables Environ to conduct a project feasibility study to explore trends, feedstock availability and potential markets, technical studies for the operation of the plant and facility, as well as overall project schedule, financial modelling and analysis.

In parallel, Honeywell UOP will provide Environ with technical and commercial information and analysis and broader project support.

“We are fully invested along the entire waste value chain and moving into chemical recycling is a natural evolution of our scope of work,” said Omar M. El Hassanein, CEO for the Waste Treatment and Resource Recovery division within Intro Sustainable Resources. “We are always on the lookout for innovative technologies that will help us decarbonise our customers’ operations and contribute to the country’s NDCs. We see Honeywell’s UpCycle Process technology as a key enabler of this objective and are looking forward to working with Honeywell towards the deployment of this technology in Egypt.”

Honeywell is a world leader in sustainability-related innovation, combining this capability with a long legacy in technology for the digitalization of industries as part of the Fourth Industrial Revolution. While pursuing its own goal of becoming carbon neutral across its operations and facilities by 2035, Honeywell is supporting similar sustainability initiatives declared by nations, and their industries, across the Middle East and North Africa.

The MoU, which was signed during the COP27 conference in Sharm El-Sheikh, Egypt, supports the objectives of Egypt’s Vision 2030 – a unified long-term political, economic, and social vision developed in alignment with the United Nations Sustainable Development Goals (SDGs). Packaging-recycling -Plastics-circularity

Under Vision 2030 Egypt has set a target to reduce greenhouse gases (GHGs) by 10 percent from the energy sector, including oil and gas, by 2030 compared to 2016 levels. Additionally, Egypt’s National Climate Change Strategy aims to increase the share of renewables in its power mix to 42 percent by 2035 and intends to invest US$10 billion to develop 10 GW of renewables and upgrade its thermal power plants.

Operating from the North African hub in Cairo, Honeywell has been expanding its presence, activities and investments in Egypt as it works with some of the country’s key government and private sector entities in the fields of oil and gas, refining and petrochemicals, smart cities, building automation, defense, aviation, infrastructure development, logistics, security and fire safety. The company has been present in Egypt for more than 60 years and is committed to providing high quality talent and technological opportunities that support the country’s long-term focus on localization.

-November contract prices of PE and PP in Europe increased

November’s contract prices for polyethylene (PE) in Europe rose by EUR20 per tonne amid both the prolongation and the rise in monomer prices in November,ICIS reported.

Contract prices for polypropylene (PP) in Europe rose by EUR10 per ton, which also reflects the increase and prolongation of raw material prices.

Spot prices were stable against the background of low purchasing activity, performed mainly within existing ranges. Prices for some items were lower, particularly high-pressure polyethylene (LDPE), including for imports for delivery in January and later.

Supplies are generally balanced across Europe. TotalEnergies customers faced a delay in deliveries due to strikes at refineries earlier this month. Packaging-recycling -Plastics-circularity

According toMrC ScanPlast, in the first nine months of 2022, the estimated consumption of polyethylene (excluding exports to Belarus and Kazakhstan) amounted to 1,874.28 thousand tons, which is 4% more than in the same period a year earlier. Supplies of LDPE and LDL have increased exclusively. Deliveries of polypropylene to the Russian market in the first nine months of the year amounted to 958.19 thousand tons (calculated according to the formula production + import – export), which is 15% less than a year earlier. Supplies of all types of polypropylene from both domestic producers and imports decreased.

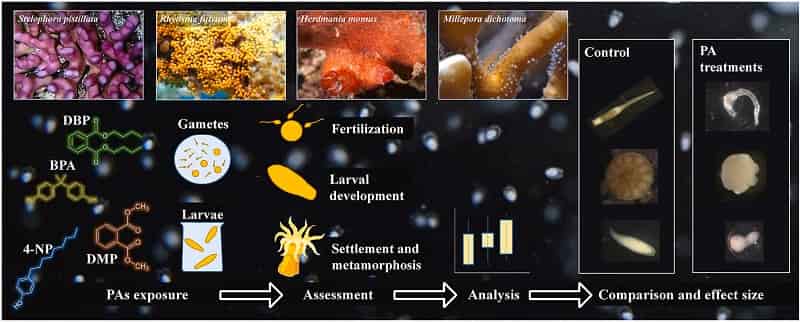

-Plastic additives harm the sea and corals’ reproductive processes – TAU study

The researchers examined four chemical additives that are widely used in plastic products and have been found in seawater in tropical areas.

Many plastic additives – chemicals that are mixed with plastic products during manufacturing –are known to be compounds that disrupt the endocrine (hormonal) system of the human body as well as damage corals and other marine creatures.

A new study by Tel Aviv University (TAU) and the Interuniversity Institute for Marine Sciences in Eilat examined the effect of plastic additives on the reproductive process and larvae development of corals and other organisms commonly found in the coral reef of Eilat. The new study published in the prestigious journal Environmental Pollution shows that these chemicals can have species-specific effects that may damage the population structure and biodiversity of coral reefs. Packaging-recycling -Plastics-circularity

The study, entitled “Limited effects of environmentally-relevant concentrations in seawater of dibutyl phthalate, dimethyl phthalate, bisphenol A, and 4-nonylphenol on the reproductive products of coral-reef organisms,” was led by doctoral student Gal Vered of the Interuniversity Institute for Marine Sciences in Eilat and TAU and Prof. Noa Shenkar of TAU’s School of Zoology in the Wise Faculty of Life Sciences and the Steinhardt Museum of Natural History.

How did the researchers conduct their study?

The researchers focused on four organisms – a stony coral, a soft coral, a fire coral and a solitary ascidian. These organisms play an important role in the ecology of tropical coral reefs, and damage to their reproduction and development may affect the structure of the reef community.

They also examined four chemical additives that are widely used in plastic products and have been found in seawater in tropical areas inhabited by coral reefs. Two of these were phthalate chemicals, which are used to soften and increase the flexibility of different types of plastic and can be found in a wide variety of consumer products such as food packaging, toys, medical devices, and adhesives. The others were 4-nonylphenol a stabilizer used in plastic packaging and as an additive in cleaning agents, and bisphenol A found in polycarbonate plastic that is used for food and beverage packaging, baby bottles, boxes, and more.

The European Chemicals Agency has classified bisphenol A as a substance that may cause damage to human fertility, based on evidence found in lab animals.

Interference with their hormonal systems may affect the chances of success of these processes, and an uneven effect on the different species may lead to a change in the community’s structure and damage to the entire system.”

Doctoral student, Gal Vered, of the Interuniversity Institute for Marine Sciences in Eilat and TAU Packaging-recycling -Plastics-circularity

“Plastic additives are chemical additives that are incorporated into plastic products during the manufacturing process,” said Vered. “These substances reach marine environments through plastic waste and wastewater. Some of them are known to activate or suppress hormonal processes, and can therefore disrupt biological systems, but their effects on organisms in coral reefs have hardly been studied. The structure of the coral reef population depends on the success of the reproduction, development and settlement of corals and other reef organisms. Interference with their hormonal systems may affect the chances of success of these processes, and an uneven effect on the different species may lead to a change in the community’s structure and damage to the entire system.”

“Climate change, ocean acidification, and ongoing anthropogenic stressors place coral reefs at existential risk. Most of the coral reefs in the world are found in developing countries where the human population is expanding rapidly and waste management is lacking,” Vered continued. “Steps towards preventing plastic waste from reaching the environment include proper local waste management that reduces transportation of waste, and sustainable consumption of products regulated for additives.”

The researchers conducted a series of exposure experiments in which the effects of the plastic additives were tested at environmentally relevant concentrations in seawater and at higher laboratory concentrations. The parameters measured were fertilization, larvae development, larvae survival and larvae settlement and metamorphoses.

The environmentally-relevant concentration of 4-nonylphenol was found to inhibit larvae settlement in the soft coral, while a high concentration of the same compound damaged the fertilization, development and settlement of all the studied organisms. The higher laboratory concentration of one of the studied phthalate chemicals damaged the settlement only of the stony coral larvae, and not of the other organisms’ reproductive products. These findings add to the accumulating evidence that plastic pollution has a selective effect on different species. Packaging-recycling -Plastics-circularity

“Our findings demonstrate plastic additives’ negative and selective effects on the development and reproduction of coral reef organisms. The environmentally-relevant concentrations used in our experiments were concentrations found in seawater; alarmingly, some had deleterious effects on organisms’ reproduction,” added Shenkar. “Nevertheless, concentration within organisms’ tissues may reach higher levels as these compounds can potentially bioaccumulate. To better understand the impact of plastic additives on this endangered ecosystem, we suggest developing better methods for measuring the actual concentrations within the tissues of the organisms to produce relevant risk assessments.”

-PepsiCo partner Northern Bottling Company trusts Sidel to install its highest-speed complete PET line

With increasing demand forecast for soft drinks in Pakistan in 2023, PepsiCo partner Northern Bottling Company is relying on Sidel to install a high-volume, high-speed carbonated soft drinks (CSD) line.

Sidel is applying its leading packaging solutions expertise to create the new complete line for Haidri Beverages Group’s subsidiary, Northern Bottling Company (NBC), in the city of Peshawar. Packaging-recycling -Plastics-circularity

Northern Bottling Company is the market leader in beverages for Pakistan’s northern region and has been a successful PepsiCo franchise for over 25 years.

Offering a capacity of over 45,000 bottles per hour, the line represents a new era of innovative technologies, high efficiency and productivity in Pakistan’s beverage industry. The new line will help unlock further capacity for Northern Bottling Company, which itself has seen volume growth of 30 percent in the year 2021-2022.

It will handle four bottle sizes and five recipes, producing PepsiCo beverages Pepsi, 7up, Mirinda, Pepsi Diet and Sting energy drinks in 300ml, 345ml, 500ml and 1500ml formats.

Serving a dynamic market

Sidel is enlarging its local expertise in Pakistan, a dynamic market where PepsiCo and NBC are playing a significant role.

“Sidel’s absolute commitment to service, along with their unique ability to optimise layout within a high-speed line equipped with cutting-edge technologies has impressed us. These were the key reasons that we have entrusted Sidel with our new investment,” says Ali Navaiz, Group Chief Operating Officer, Haidri Beverages Group.

“We are excited by this collaboration,” adds Vedat Guler, Sales Director Middle East, Sidel. “We’re dedicated to helping NBC achieve its commercial, sustainability and efficiency goals by adding value with our innovative bottle design and lower energy and resources solutions.”

Sustainable production

Sidel’s complete line will help NBC save energy and resources. In fact, Sidel’s Combi can blow bottles using the lowest possible blowing pressure, and the air is recycled It also offers water savings on bottle base cooling. The line can run recycled PET (r-PET) bottles, and with Sidel’s patent StarLite bottle base, NBC and PepsiCo’s future sustainability goals will be met. The innovative StarLite bottle base optimises the quantity of PET per bottle, contributing to sustainability by reducing material use and lowering emissions during transport. Packaging-recycling -Plastics-circularity

Reduced Total Cost of Ownership

Sidel is confident of meeting NBC’s high-performance targets and expectations, knowing that its line engineering and technology, innovative solutions, resource efficiency and packaging design improvements, together with its local service and aftersales support, will add value and reduce the Total Cost of Ownership (TCO).

–Commission proposes certification of carbon removals to help reach net-zero emissions

The proposal will boost innovative carbon removal technologies and sustainable carbon farming solutions and contribute to the EU’s climate, environmental, and zero-pollution goals.

The proposed regulation will significantly improve the EU’s capacity to quantify, monitor, and verify carbon removals. Higher transparency will ensure trust from stakeholders and industry, and prevent “greenwashing.” Carbon removals can and must bring clear benefits for the climate, and the Commission will prioritise those carbon removal activities that will provide significant benefits for biodiversity.

Moving forward, the Commission, supported by experts, will develop tailored certification methods for carbon removal activities that deliver on climate and other environmental objectives. Packaging-recycling -Plastics-circularity

To ensure the transparency and credibility of the certification process, the proposal sets out rules for the independent verification of carbon removals, as well as rules to recognise certification schemes that can be used to demonstrate compliance with the EU framework. To ensure the quality and comparability of carbon removals, the proposed regulation establishes four QU.A.L.ITY criteria:

- Quantification: Carbon removal activities need to be measured accurately and deliver unambiguous benefits for the climate;

- Additionality: Carbon removal activities need to go beyond existing practices and what is required by law;

- Long-term storage: Certificates are linked to the duration of carbon storage to ensure permanent storage;

- Sustainability: Carbon removal activities must preserve or contribute to sustainability objectives such as climate change adaptation, the circular economy, water and marine resources, and biodiversity.

This proposal is essential to the EU’s goal of becoming the world’s first climate-neutral continent by 2050. To achieve this goal, the EU needs to reduce its greenhouse gas emissions to a minimum. At the same time, the EU will have to scale up the removal of carbon from the atmosphere to balance out emissions that cannot be eliminated.

Industrial technologies, such as bioenergy with carbon capture and storage (BECCS) or direct air carbon capture and storage (DACCS), can capture carbon and store it permanently. In agriculture and forestry, carbon farming practices can sustainably enhance the storage of carbon in soils and forests or reduce the release of carbon from soils, creating a new business model for farmers and foresters. Long-lasting products and materials, such as wood-based construction products, can also keep carbon bound for several decades or longer. Packaging-recycling -Plastics-circularity

Today’s proposal will promote cutting-edge clean technologies and support the New European Bauhaus by recognising the carbon storage capacity of wood-based and energy-efficient building materials. The proposal will enable innovative forms of private and public financing, including impact finance or result-based public support under state aid or the Common Agricultural Policy. The Commission will continue funding carbon removal action on the ground through the Innovation Fund (which can finance BECCS and DACCS projects, among others), the Common Agricultural Policy, the Regional Development Fund, the LIFE programme, and the Horizon Europe programme (including the Mission ‘A Soil Deal for Europe’).

Next steps

The Commission proposal will now be discussed by the European Parliament and the Council, in line with ordinary legislative procedure. Based on the QU.A.L.ITY criteria, the Commission will develop tailored certification methodologies for the different types of carbon removal activities, supported by an expert group. The first meeting of the expert group is planned for the first quarter of 2023.

Source: European Commission

Packaging-recycling -Plastics-circularity