Petrochemical SustainableSources BOPET 14-11-2020 - Arhive

Petrochemical SustainableSources BOPET

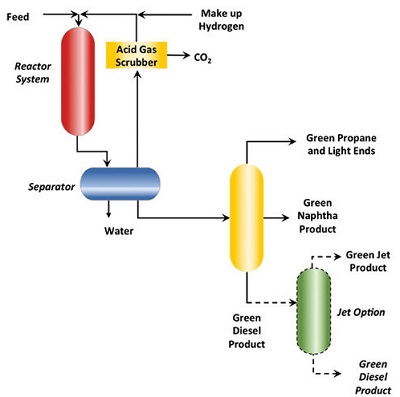

-Total to use Honeywell UOP’s Ecofining™ process technology to produce renewable fuels

Honeywell UOP has announced that French energy company Total will utilize Honeywell UOP’s Ecofining™ process technology to produce renewable fuels, primarily for the aviation industry, at its Grandpuits platform at Seine-et-Marne in north central France. Once completed, the bio-refinery will process 400,000 tons of feed per year, producing up to 170,000 tons of sustainable aviation fuel, 120,000 tons of renewable diesel and 50,000 tons of renewable naphtha for production of bioplastics.

UOP will provide technology licenses, basic engineering, specialty equipment, and catalysts for the project.

-ADNOC and Total sign agreement to jointly explore CO2 emissions reductions

The Abu Dhabi National Oil Company (ADNOC) has signed a strategic framework agreement with Total to explore joint research, development and deployment partnership opportunities in the areas of CO2 emission reductions and carbon capture, utilization and storage (CCUS), where ADNOC is an industry leader. Petrochemical SustainableSources BOPET

The agreement brings together the best-in-class in low carbon technologies from ADNOC and Total and expands on the long-standing partnership and collaboration between the two leading energy producers across the full value chain.

The agreement was signed by His Excellency Dr. Sultan Ahmed Al Jaber, UAE minister of Industry and Advanced Technology and ADNOC Group CEO, and Patrick Pouyanné, CEO of Total.

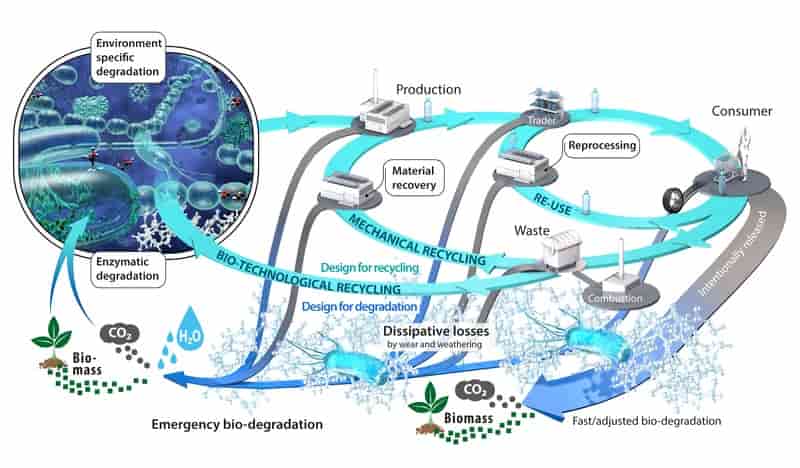

-Possibilities and limitations of biotechnological plastic degradation and recycling

Researchers group found six principles to get plastics into circulation – progressions in microbial recycling you may just find with PET

Considerable research achievements were made to address the plastic crisis using biotechnology, but this is still limited to polyesters. Petrochemical SustainableSources BOPET

This Comment aims to clarify important aspects related to myths and realities about plastic biodegradation and suggests distinct strategies for a bio-based circular plastic economy in the future.

Numerous types of plastics have been made, with a further doubling of the plastic industry size to a staggering 800 million tons per year predicted by 2040 (ref. 1).

With landfills being no longer a viable option for their end-of-life treatment in a circular economy, plastic recycling aiming at material recovery is a necessity and of high importance for resource saving, thereby reducing CO2 emissions by stepwise replacement of other less eco-friendly processes, such as incineration2.

While mechanical and to some extent chemical recycling, such as solvolysis of polyethylene terephthalate (PET) and pyrolysis of mixed plastics containing polyolefins, are being applied in industry3, the possibilities of biotechnological plastic degradation and recycling are often overlooked.Indeed, as reported by Yoshida etal. in Science, even a wild-type bacterium (Ideonella sakaiensis) was identified as being able to grow on and assimilate PET, albeit very slowly4.

This has been a major discovery, especially in light of natural evolution, as commented on in Science5. Recently, scientists have identified and engineered enzymes to meet requirements for efficient depolymerization and recycling of PET on an industry-relevant scale and processing time, as described by Tournier et al. in Nature6.

Considering that biotechnological degradation and recycling of plastics is still at the very early stage of the learning curve, these results are very promising.In this context, we wish to clarify certain aspects as motivated by numerous stakeholder engagements with journalists in all media types — as well as university students to primary school pupils — to enable well-founded public debates among all end-users of plastics.

Chemical bonds determine the bio-recyclability of plastics

Only few plastic materials — containing hydrolysable bonds like esters or amides — can be, in principle, enzymatically converted into well-defined oligomers or monomers that can be reused to make virgin plastics or upcycled to higher-value products.

This includes PET (which yields terephthalic acid and ethylene glycol) and synthetic polyamide (PA; yields diamine/diacids or ω-amino carboxylic acids). For selected types of polyurethane (PUR) only parts can be eventually recycled due to a more complex chemical composition. To date, enzymes with significant PA and PUR depolymerizing activities are, however, not yet scientifically described.

-OPINION: Oxo-biodegradable plastic and bans

OPINION: Michael Stephen is a barrister, former MP, and director of Symphony Environmental Technologies Plc, a company which develops additives for biodegradable plastics. In this article he discusses the proposed ban on what is termed ‘oxo-degradable’ plastic. Petrochemical SustainableSources BOPET

I write this opinion in light of the article WRAP caught up in degradable plastics row and previous reports.

Symphony Environmental Technologies Plc would support a ban on oxo-degradable plastic – which is essentially ordinary or photo-degradable or bio-based plastic that creates microplastics but does not biodegrade in the open environment – but oxo-BIOdegradable plastic is an entirely different technology.

On 29 October, Symphony received a letter from the Rt. Hon. Theresa Villiers MP, who said: “I am writing to say that as a former UK Secretary of State for the Environment I see no justification for banning oxo-BIOdegradable plastic. In fact I consider it highly desirable that everyday plastics should be made so that they will biodegrade much more quickly if they get into the open environment and will not lie or float around for decades.”

-M&As: Nova Chemicals to sell EPS business to Alpek; Clariant re-launches sale of pigments unit

In a bid to refocus on its core olefin and PE business, Canada-based Nova Chemicals Corporation is selling its expandable styrenics (EPS) business to a subsidiary of Mexican chemical firm Alpek S.A.B. The parties expect to close the transaction in the fourth quarter. Headquartered in Calgary, Alberta, and wholly-owned by Mubadala Investment Company of UAE, Nova says it will use the funds as additional investments to advance a global circular economy for plastic. Petrochemical SustainableSources BOPET

Alpek subsidiary Styropek will acquire two US facilities producing 168,000 tonnes/year of EPS. The business consists of two product lines: EPS and Arcel resin, with manufacturing facilities in Pennsylvania and Ohio, along with commercial operations in Asia.

-INEOS Styrolution and Ferrero explore advanced recycling for future packaging solutions

INEOS Styrolution has announced an agreement with Ferrero to explore the feasibility of using its advanced recycling concepts such as depolymerisation for future packaging solutions. Petrochemical SustainableSources BOPET

The aim of INEOS Styrolution is to develop a process to convert complex plastic waste back to fully recyclable materials that comply with food contact regulations.

The INEOS Styrolution recycling concept aims at contributing to a circular economy, based on the depolymerisation process that converts post-consumer complex plastic waste back to its monomers. The new material created through this process would also comply with food contact regulations.

2020 has been an incredibly challenging year for the world, and the remaining weeks will not change that picture. The fall-out from the US elections, the cliff-edge scenario posed by a no-deal Brexit, the second wave of COVID infections and the related restrictions to economic activity to help contain the spread, and renewed incidents of fundamentalist attacks on human and democratic values: all of these ask for leadership and clear directions to strengthen the resilience of our society. Petrochemical SustainableSources BOPET

Relations between Europe and the USA are expected to improve with President-elect Joe Biden taking office in 2021, but Donald Trump still has some 70 days to cause tension on the international scene, whether by his own actions or by others misusing the void in direction and diplomacy for their own interests. This may contribute to further uncertainty in the global economic outlook.

-IOM3 welcomes UK plastic packaging tax

UK HMRC has published the draft legislation for the introduction of a new tax on plastic packaging with less than 30 per cent recycled content. This is to take effect from April 2022. IOM3 welcomes the announcement. Petrochemical SustainableSources BOPET

IOM3 CEO Dr Colin Church said: “It is good to see progress being made on this important issue. Creating strong demand for recycled plastic is a key element of moving to a more circular economy, which in turn will both help tackle the marine plastic pollution problem and support the world’s efforts to avoid harmful climate change.”

However, IOM3 was disappointed that the government has chosen to retain the proposed position for transport packaging to exclude packaging used for transporting imported goods but include packaging used for transporting exports. The different tax treatment for imports and exports risks disadvantaging UK manufacturers, according to an IOM3 press release.

-Vynova pioneers production of circular-attributed PVC

Vynova has launched the world’s first range of certified circular-attributed PVC resins. The innovative PVC portfolio is manufactured using circular ethylene which is produced from mixed plastic waste, helping close the loop on plastics recycling.

The new circular-attributed PVC is produced using ethylene which is made from pyrolysis oil as feedstock. This feedstock is produced from mixed plastic waste streams via pyrolysis – a chemical recycling process in which plastic waste is heated without oxygen.

This approach contributes to sustainable management of difficult to recycle plastic waste streams, advancing the journey towards a circular economy. Furthermore, the pyrolysis oil replaces conventional fossil feedstock, resulting in a CO2 emission reduction of 50 per cent. The circular ethylene is supplied to Vynova by SABIC from the company’s production facilities in Geleen (the Netherlands). Petrochemical SustainableSources BOPET

-Evonik, Linde develop membrane-based technology to extract hydrogen from natural gas

Evonik Industries and Linde say that their joint membrane-based technology for natural-gas processing can efficiently separate hydrogen from natural gas blend at the point of extraction, according to Chemweek.

The companies say that a demo plant at Linde’s Dormagen, Germany, site will act as a showcase for the efficiency and cost effectiveness of their joint technology. Further details have not been disclosed. Petrochemical SustainableSources BOPET

“The economic viability of extracting hydrogen from the current natural gas infrastructure depends largely on the efficiency of the gas separation technology. Membrane selectivity is a key success factor,” says Harald Schwager, deputy chairman of Evonik.

Petrochemical SustainableSources BOPP 13-11-2020

Petrochemical SustainableSources BOPET