Petrochemical SustainableSources Packaging 07-11-2020 - Arhive

Petrochemical SustainableSources Packaging

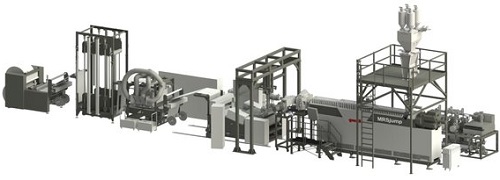

-Gneuss launches new MRSjump for unique PET Tray-to-Tray recycling

Gneuss has developed the innovative MRSjump Extruder, for the process of tray-to-tray recycling,

The new MRSjump Extruder combines the high decontamination performance of the MRS degassing extruder, which has been well established over the past decades, with a viscosity boost.

The MRSjump extrusion process does not necessitate any pre- or post-treatment of the input material, such as crystallisation or pre-drying of the recycled material or an IV boost in a solid state polycondensation (SSP).

The high degassing efficiency of the MRSjump Extruder makes it possible to comply with EFSA and FDA limits without time- and cost-intensive upstream or downstream material treatment.

Hengli to use Invista tech for two PTA lines in China

Invista’s technology and licensing group, Invista Performance Technologies (IPT), and Hengli Petrochemical (Huizhou) Co, a subsidiary of Hengli Group (Hengli), have reached agreement to license Invista’s P8 purified terephathalic acid (PTA) technology for two PTA lines. These two lines will be installed at Xiachong, Daya Bay, Huizhou City, Guangdong province, China. Petrochemical SustainableSources Packaging

Hengli is also operating another five PTA lines on Changxing Island (Dalian), all of which utilise Invista’s PTA technology, with a total capacity of 12 million tonnes/year.

-Are new food and biomass technologies more sustainable? A Review

The new nova paper #14 gives an overview on the status and sustainability assessments of new food and biomass technologies such as organic farming, insect protein, artificial meat, precision agriculture, vertical urban farming and improved plant varieties

20-11-04-nova-paper-14_Thumbnail_NLThe results of the review are summarised in „key facts“ for each technology. Petrochemical SustainableSources Packaging

Most modern food and biomass production technologies have both positive and negative aspects that are, to a certain degree, interdependent. The apparent incommensurateness of animal welfare and low environmental impacts in (organic) livestock production is a good example for the challenges of sustainable food production.

-PVC recycling reaches a new high in UK and Ireland

According to Recovinyl the UK and Ireland collected and recycled a total of 143,428 tonnes of waste PVC across all PVC recycling formats in 2019. Within this total, PVC window profiles accounted for 86,057 tonnes, according to latest industry figures.

The UK’s achievement represents 18.6% of the 771,313 tonnes of waste PVC recycled throughout Europe in 2019 – a new record high and 4.3% up on the previous year, second only to Germany. Petrochemical SustainableSources Packaging

Recovinyl, the PVC industry’s recycling scheme, was the largest contributor to this total and registered a total of 769,233 tonnes of PVC waste entirely recycled in Europe in 2019.

-Asia Chemical Conference 2020: COVID-19 a windfall for ABS producers

Consumption of acrylonitrile-butadiene-styrene (ABS) has surged as a result of home quarantines imposed by the spread of COVID-19, with producers’ cash margin in excess of USD500/metric ton in 2020 and expected to rise above $600/metric ton in 2021, said Daniel Siow, IHS Markit director/styrenics on Thursday at the eighth Asia Chemical Conference, being held by IHS Markit in a virtual format, as per Chemweek.

The global economy was plunged into despair when COVID-19 first hit in early 2020 and a second wave is now recurring in major European countries and the US.

This has meant that cities have to be locked down and working or schooling from home has become the norm until an effective vaccine can be discovered and large populations inoculated. Petrochemical SustainableSources Packaging

-Upcycling used mixed plastic back to the original polymer

In the summer, Unilever’s ice cream brand Magnum announced the rollout of recyclable ice cream tubs made with recycled polypropylene (rPP), following a successful pilot launch in Spain, Belgium, and the Netherlands last year. The rPP was developed in cooperation with Sabic. Petrochemical SustainableSources Packaging

Packaging Europe spoke to Mark Vester, Circular Economy Leader at SABIC, to find out more about food-grade rPP and the company’s TRUCIRCLE™ portfolio.

What challenges had to be overcome to make rPP suitable for food contact?

Consumers rightly expect packaging to become more sustainable and more recyclable. By using more sustainable materials to manufacture new products and transforming previously unrecyclable plastic into a valuable material, we can help protect our planet’s natural resources. SABIC was the first petrochemical company to scale-up processes to recycle used mixed plastic back to the original polymer for commercial application.

-Double Planetary Mixers Granulate and Dry

High-precision mixing, granulation and vacuum drying in a single vessel.

The Ross Double Planetary Mixer is billed as an ideal machine for high-precision mixing, granulation and vacuum drying—all in a single vessel. Powders and granules are gently blended by two rectangular planetary blades that rotate on their own axes while orbiting the mixing zone on a common axis.

Atomizing spray nozzles enable controlled and spill-free addition of liquid raw materials as the mixing blades continuously ensure uniform composition and temperature throughout the batch. Petrochemical SustainableSources Packaging

As a result, granulation and drying procedures can reportedly be completed in significantly shorter times compared to conventional, non-vacuum granulators and dryers.

-Germany’s BASF puts India joint chemical complex plan on hold due to pandemic

BASF has placed a plan for a chemical complex in Mundra, India on hold due to uncertainties arising from the coronavirus pandemic, the German chemicals major said in a joint statement on Thursday. Petrochemical SustainableSources Packaging

BASF on 4 October last year signed a memorandum of understanding (MoU) with the Abu Dhabi National Oil Company (ADNOC), Indian conglomerate Adani Group and Austria’s Borealis to evaluate collaborating on the chemical complex in Gujarat state.

The joint feasibility study for the complex has been completed, BASF said in a statement.

“The global economic uncertainties caused by the pandemic have led the Partners to review the timing for undertaking this investment,” it said.

-Braskem launches portfolio for 3D printing in South America

Polypropylene filaments, pellets and powder can be used in industrial and desktop printers to make processes more versatile and to make more resistant and stable pieces

Braskem, taking another important step in its innovation strategy, launches this month a portfolio of exclusive products for the additive manufacturing segment, popularly known as 3D printing, which is experiencing robust growth in Brasil. The market, whose main characteristics are decentralization of production and customization of solutions, also has helped to combat the novel coronavirus with the production of face shields and components for mechanical respirators, for example. Petrochemical SustainableSources Packaging

Braskem’s solutions made from polypropylene (PP) have proved attractive and ideal for additive manufacturing, given the recyclability, impact strength and dimensional stability of the raw material, which features the capacity to make durable hinges and lower density than other types of plastics. PP for 3D printing can be found in the form of pellets and filaments, both of which are produced in Brazil, and powder, which is imported from the United States. The products also can be used in both industrial and desktop 3D printers.

SRF to set up 2nd BOPP film line in Indore

Indian film packaging maker SRF is to set up a second BOPP film line with a metalliser at its Indore plant, either directly or through a wholly owned subsidiary.

The existing capacity is 45,000 tonnes/year and will be upped to 60,000 tonnes/year of additional capacity. The new capacity should go on stream within 20 months.

The rationale for expansion is the growth of BOPP market both in India and overseas, and the need for ability to service the customer for the entire spectrum of BOPP products, says the firm. Petrochemical SustainableSources Packaging

Petrochemical SustainableSources Packaging