Petrochemicals Batteries Carbon Fibers 22-11-2021 - Arhive

Petrochemicals Batteries Carbon Fibers

Adipic Acid Nylon Petrochemicals

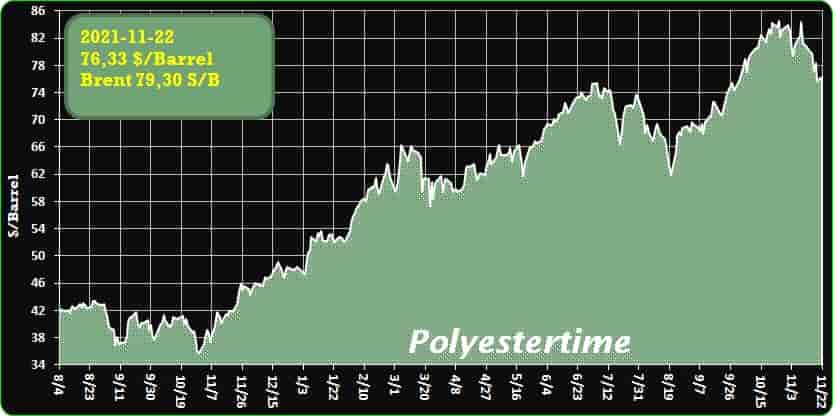

Crude Oil Prices Trend

-Arkema Accelerates Its Investments in Batteries

In the presence of Thierry Le Hénaff, Chairman and CEO of the Group, Arkema today inaugurates the Christian Collette Center of Excellence dedicated to batteries at its Pierre-Bénite Research Center. On this occasion the Group will announce a 50% increase in its Kynar® PVDF fluoropolymer production capacities at its Pierre-Bénite site in order to address the fast-growing demand for materials for lithium-ion batteries. Arkema now aims for sales of at least one billion euros in batteries by 2030.

In a context of rapidly accelerating growth in electric mobility around the world, but also for stationary uses, renewable energy storage and electronics, improvements in battery performance, including greater energy density and shorter charging time, greater autonomy and lighter weight of vehicles, today represent key R&D areas to meet the challenge of energy transition. Petrochemicals Batteries Carbon Fibers

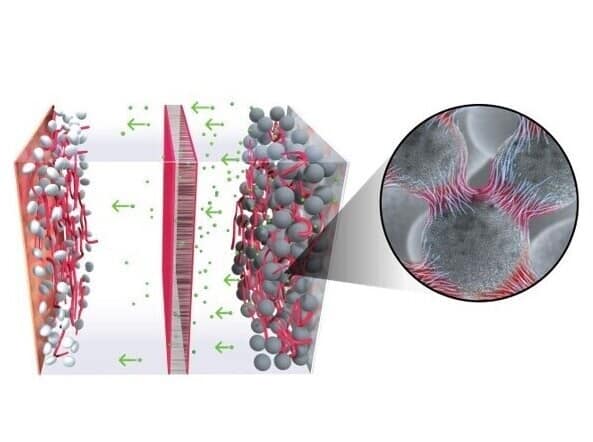

Thanks to its recognized expertise and unique offering of innovative, durable and high-performance materials, Arkema is ideally positioned at the heart of the battery ecosystem to support its customers and partners in the clean mobility revolution. Arkema is thus one of the world’s leading suppliers of high value-added solutions: PVDF for binders and separator coatings, lithium salts to improve cell performance, smart adhesives for cell-to-cell bonding, and bio-based polyamide 11 to cool battery lines.

This Center of Excellence dedicated to batteries for clean mobility is equipped with state-of-the-art design and analysis equipment, including a dry room and an electrode coating line. It draws on the scientific and technical complementarity of the Pierre-Bénite Research Center’s researchers. This Center of Excellence, which will help accelerate the development of advanced materials and processes for future generations of more efficient, safer and more compact batteries, was partly financed by the Région Auvergne-Rhône-Alpes.

Alongside this platform, a pilot line dedicated to the pre-industrialization of the next generations of electrolytes for the batteries of the future is already operational.

This new Center, named the Christian Collette Center of Excellence for Batteries, in honor of the Group’s R&D Vice President who passed away last April, is inaugurated in the presence of numerous customers, partners, and representatives of the State, the Region and the City.

-Fast fashion is killing the planet. These chemists are fighting back

Your clothes are mostly plastic. These chemists have figured out how to recycle them.

ur clothes don’t die — or, at least the non-biodegradable textiles that they’re made of don’t usually get a second life.

“Textiles are these complex mixtures of different materials,” says Moby Ahmed, the CTO of Ambercycle, a textile recycling startup. Examples are cotton, polyester, spandex, nylon, and acrylic — so basically, most of the materials that make up the clothes in your closet.

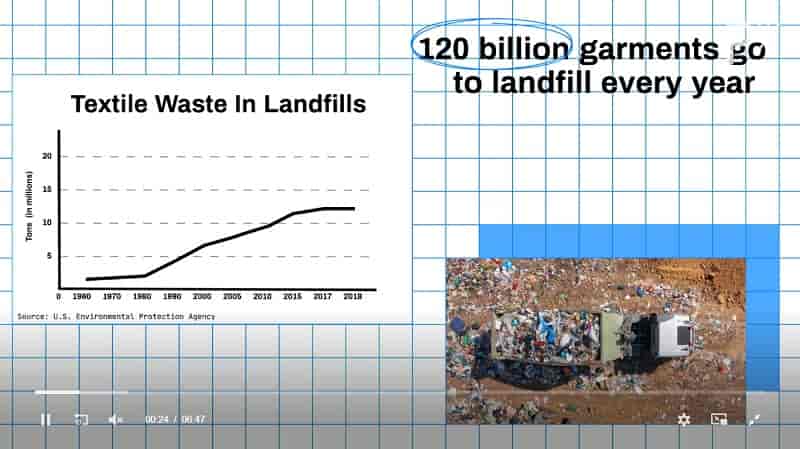

In 2018 alone, 11.3 million tons of those textile mixtures waste ended up in landfills, the EPA says. And the lion’s share of that waste comes from clothing — over a billion garments worth. Petrochemicals Batteries Carbon Fibers

Fast fashion — a term used to describe an industry that relies on fast manufacturing and styles that quickly go out of vogue — is reliant on these textiles. A June 2021 report by London’s Royal Society for Arts (RSA) found that more than 80% of some offerings on websites contained new plastic in them, and despite recent media attention, clothing companies are still slow to adopt truly recycled garments into their product lines.

-US R-PET market evolving amid supply tightness

Both recycled polyethylene terephthalate (R-PET) flake and pellet prices remain high, on strong demand due to sustainability commitments from major consumer brands.

Amid the market tightness, some suppliers have shifted their sales away from the fibre industry towards packaging.

This move is due to the premium that packaging grade or food grade R-PET commands, as well as the demand stability expected over the next several years as post-consumer recycled (PCR) content commitments and mandates grow.

In 2020, 38% of US and Canada R-PET material was used in the fibre market, down from 47% in 2018, according to statistics from the National Association for PET Container Resources (NAPCOR). Petrochemicals Batteries Carbon Fibers

The fibre market historically targeted the lower priced curbside based R-PET material as product specifications were more flexible for fibre applications.

Curbside grade is derived from sorting general consumer mixed-recycling collection. These bales typically have higher levels of wastage. This is due to contact with food waste or other plastics such as polyvinyl chloride (PVC) which act as contaminants. Traditionally, curbside grade prices trail premium grade.

Premium grade constitutes bottles collected from deposit return scheme (DRS) programmes, also termed bottle bill programmes. DRS collection systems typically result in lower contamination, thus resulting in higher recyclate yield.

One West Coast recycler noted curbside bottle bale quality degradation throughout the last year, with useable bottle feedstock yields as low as 50%. Historically, curbside bottle bale yields hovered around 60%. Curbside bale quality is very dependent on sortation technology or method and can require additional capital or production time to improve.

-An expert view on Coca-Cola’s new 100% plant-based bottle

Is Coca-Cola’s 100% plant-based bottle really better for the environment than PET alternatives? The answer to that question isn’t as simple as you might think, says Mario Grimau, a polymer engineer and materials science specialist at SPRING.

It has been a very long journey for Coca-Cola to reach its first 100% bio-based PlantBottle, since the Plant PET Technology Collaborative (PTC) project was announced in April 2012, originally signed by Coca-Cola and other big four brands. A working group focused on accelerating the development and use of 100% vegetable PET bottles and PET fibers, both based on BioPolyethylene Terephthalate or BioPET.

In fact, Coca-Cola’s journey to sustainability had already begun in 2009, when the original PlantBottle was introduced. Petrochemicals Batteries Carbon Fibers

This concept was so successful that after a year 2.5 billion bio-based PlantBottle bottles had already been manufactured. However, BioPET bottles at that time were only partially bioplastics, since only one of the monomers to obtain PET, the MEG, was obtained from biomass; which in this case was sugar cane.

PET consists of two molecules: approximately 30% monoethylene glycol (MEG) and 70% terephthalic acid (PTA); of which PET is obtained through a polymerization reaction; therefore, for almost ten years, PlantBottle consisted only 30% by weight of a bio-based precursor, while the remaining 70% corresponding to the PTA was still obtained from conventional petrochemical sources.

The new Coca-Cola prototype announced this October is finally a fully plant-based bottle, made from BioMEG in combination with plant-based PTA. Obtaining this last bio-monomer has been achieved through the new BioFormPX process from Virent (Madison, Wisconsin); in which bio-sourced p-xylene (BioPX) has been converted into terephthalic acid of vegetable origin (BioPTA) by a biochemical process.

-COEXPAN launch packaging solutions for hyper-extended shelf life

COEXPAN announces a range of packaging solutions that include its COEXSHIELD monomaterial PET or PP trays for fresh food applications, which it claims can expend shelf-life from 7 to 12 days.

Developed by INNOTECH, COEXPAN’s Innovation and Technology Centre, the new range is designerd to replace complex medium and high-barrier laminates with high-barrier monomaterials that include additives suitable for food contact.

The new range is aimed at reducing food waste in line with the Sustainable Development Goals. The company says that, depending on the product’s initial hygiene and food safety conditions, it can increase shelf-life to up to 12 days.

The antibacterial features prevent bacteria growing on the outer packaging of fresh food, according to COEXPAN. It is a rigid plastic solution that can be developed in combination with Emsur and its EMFULL barrier lids, which are apparnelty designed to allow complete recyclability of the tray. Petrochemicals Batteries Carbon Fibers

Included in the range is the COEXSHIELD RAM 0, an antibacterial tray containing a virucidal additive based on copper micro- and nanon-particles, which is effective against COVID Sars II and FDA approved. The COEXSHIELD Infinite contains antibacterial powder that is effective against E. Coli and C. Yeyuni, while the COEXSHIELD Fresher is an anti-odour scavenging tray that eliminates smells and acid-aliphatic-sulfur compound families; both are FDA and EFSA compliant.

-Toray to expand carbon-fiber manufacturing capacity in Mexico

Toray Industries, Inc. (Tokyo, Japan) announced that U.S. subsidiary Zoltek Companies, Inc. will bolster its large-tow carbon fiber (with more than 40,000 filaments) production capacity in 2023. The upgrade will cost around $130 million (around ¥14 billion). A Zoltek facility in Jalisco, Mexico, will lift its annual capacity around 54%, to more than 20,000 tons, boosting the combined annual capacity of that company’s Mexican and Hungarian operations to about 35,000 metric tons.

Toray expects the market for this fiber to expand over the medium through long terms. That is because of growing deployments of wind power as an eco-friendly source of renewable energy. An associated factor is rising demand for longer and lighter blades to boost generating efficiency, fueling the use of carbon fiber, which is lightweight, strong, and rigid. The capacity increase will stabilize supplies to cater to expanding large tow carbon fiber demand. Zoltek will keep drawing on production facilities in the United States, Hungary, and Mexico to take advantage of increasing global demand, particularly for wind turbine blades. Petrochemicals Batteries Carbon Fibers

RGE group of resources-based companies has released its 2021 progress report on its commitment to invest USD200 million in next-generation textile fibre innovation and technology over a ten-year period which started in 2019.

The annual report provides an update on the activities undertaken by RGE’s business groups (Sateri, APR, APRIL, Bracell) involved in the fashion value chain to advance its ambition towards closed-loop, circular and climate-positive cellulosic fibre.

Bey Soo Khiang, Vice Chairman, RGE said, “Our achievements this year underscore our commitment to continuous improvement in clean production and resource utilisation efficiency. We will continue to pursue manufacturing excellence and invest in best-in-class technologies for all our facilities as part of our commitment towards closed-loop and cleaner production.” Petrochemicals Batteries Carbon Fibers

In 2021, Sateri achieved full compliance with the emission limits set out in the European Union Best Available Techniques Reference Document (EU-BAT BREF) for all of its five viscose mills in China, two years ahead of schedule. Bracell completed construction of the world’s largest and greenest new generation pulp mill in São Paulo which uses cutting-edge technology for fossil fuel-free generation.

Amid the COVID-19 pandemic continuing to restrict travel and collaboration, RGE persisted in building upon existing partnerships, while entering into new agreements. Sateri strengthened its strategic collaboration with Infinited Fiber Company, participating in the company’s EUR30 million funding round, which attracted new and existing investors such as H&M Group, Adidas, BESTSELLER and Zalando.

New partnerships formed by RGE included a five-year textile recycling research collaboration with Nanyang Technological University Singapore, and a three-year strategic partnership with the Textile and Fashion Federation Singapore which seeks, among others goals, to advance research and innovation in circular economy approaches to fashion waste in Asia.

Petrochemicals Batteries Carbon Fibers