Petrochemicals Carbon Fiber Prepreg 18-08-2021 - Arhive

Petrochemicals Carbon Fiber Prepreg

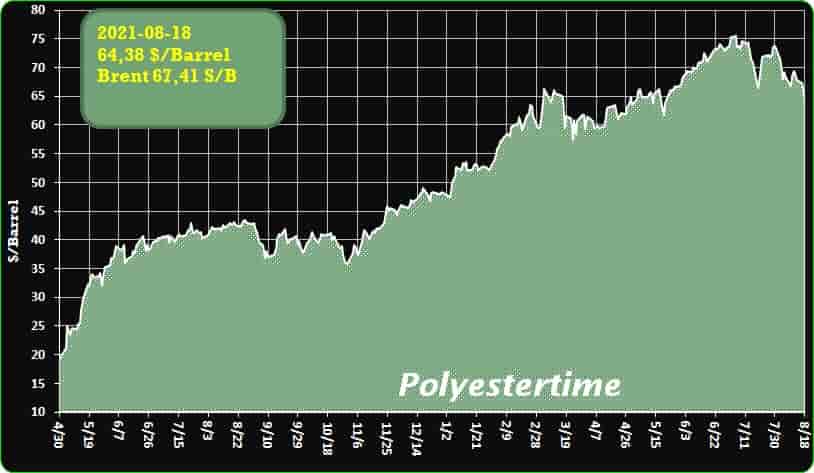

Crude Oil Prices Trend

The companies have signed a memorandum of understanding to form a joint venture that will build and operate the new plant.

Pact, Cleanaway and Asahi Beverages are already collaborating to build a PET recycling facility in Albury-Wodonga – expected to be completed later this year.

The newly announced proposal for an additional facility aims to increase the production and availability of recycled PET resin in Australia.

The proposed facility is expected to process the equivalent of around 1 billion bottles each year to produce more than 20,000 tonnes of recycled PET bottles and food packaging.

The partnership will see waste management company Cleanaway provide PET through its collection and sorting network, and Pact provide technical and packaging expertise, while CCEP, Asahi Beverages and Pact will all buy the recycled material from the plant.

-INEOS Styrolution Joins Cyclyx as Founding Member

Cyclyx International, a consortium-based feedstock management company with a mission to increase the recycling rate of plastic from 10% to 90%, announced that INEOS Styrolution, a global leader in styrenics, has joined the Cyclyx consortium as a founding member. Ricardo Cuetos, vice president, INEOS Styrolution America, will join the Cyclyx executive advisory board. Petrochemicals Carbon Fiber Prepreg

INEOS Styrolution recently announced its global plastic pledge to move toward a more circular economy for plastic packaging. The company has developed a family of products made from recycled post-consumer plastic waste as well as materials based on renewable feedstock in an effort to fulfil its vision to be recognized as the global leader in sustainable styrenics solutions. These products, marketed under the name INEOS Styrolution ECO, match the performance of the company’s existing producing portfolio while reducing its greenhouse gas footprint and reducing the amount of post-consumer waste going to landfill.

INEOS Styrolution has a strong vision for sustainability aimed at improving and increasing the recovery of post-consumer plastic waste and strengthening innovation for circularity. In his role on the Cyclyx executive advisory board, Mr. Cuetos will actively contribute to innovative advancements in the sustainability and circular economy of plastics.

As a member of the Cyclyx consortium, INEOS Styrolution will have access to the Cyclyx platform which includes an integrated set of innovations including chemical characterization of plastics and predictive modelling of feedstock sources to product pathways, custom feedstock recipes, and customized supply chains, offering INEOS Styrolution essential tools to accelerate progress on its sustainability goals.

-Bioplastic grade M∙VERA® GP1045 – Suitable for medium stiffness applications

The new M·VERA® GP1045 consists primarily of renewable resources, is home compostable and has been specially designed for injection moulding applications

As a branch of AKRO-PLASTIC GmbH, BIO-FED is the specialist for innovative and application-oriented biocompounds. The product portfolio of biodegradable and/or biobased compounds under the trade name M·VERA® is constantly being expanded with new products. Petrochemicals Carbon Fiber Prepreg

Depending on the requirements profile, these compounds are either biodegradable in various environments or suitable for long-term use – and completely or partially made from renewable raw materials.

BIO-FED supplies a wide range of M∙VERA® compounds for injection moulding. This broadly diversified portfolio contains high shares of renewable content range from 50 to almost 100 %. These materials are PLA-, PBAT- or PHA-based and certified according to standards provided by TÜV AUSTRIA Belgium.

Tove Andersen has TOMRA as president and CEO effective today. She takes over from Stefan Ranstrand, who held the position for the past 12 years, and becomes the first female President and CEO of the company. Petrochemicals Carbon Fiber Prepreg

Andersen joins TOMRA from global fertilizer company YARA International, which is also headquartered in Norway, where she was EVP for Europe.

Chairman of the TOMRA Board of directors, Jan Svensson, said: “The Board is delighted that, after a search process and her appointment as communicated before, Tove Andersen is now joining TOMRA as the company’s president and CEO.

“Tove Andersen is a proven leader with a distinguished track record, broad expertise and a passion for sustainability. Tove is a people- and customer-centred person which we believe ideally suits TOMRA in its present development stage. I am personally very pleased that we have been able to attract someone of her caliber, track record and potential.”

Andersen added: “TOMRA is a company I have known for many years. I have always been impressed by the business’s continued evolution and the position it has created for itself today globally under Stefan’s leadership.

“With the increased focus worldwide on sustainability and, in particular, the circular economy, TOMRA is more relevant than ever before and is perfectly placed to continue being a very successful company.

-Carbon-Fiber Prepreg Boasts World’s Fastest Curing Time

The carbon-fiber-reinforced prepreg sheet cures in as little as 30 seconds and can be stored at room temperature.

Japan’s DIC Corp. and its local partners have developed a fast-curing carbon-fiber-reinforced prepreg sheet that reportedly boasts the world’s fastest curing time and can be stored at room temperature. Petrochemicals Carbon Fiber Prepreg

DIC Seiren Co. Ltd. and the Industrial Technology Center of Fukui Prefecture recently completed a research project aimed at commercializing fast-curing prepreg made with carbon-fiber composites for automotive applications. It was chosen as a major research project by the New Energy and Industrial Development Organization (NEDO) and subsidized for three years from July 2018 to June 2021. The three entities also developed a mass-production process and began providing samples in July using a demonstration plant operated by Seiren.

Carbon-fiber-reinforced prepreg sheet is an intermediate material made by processing bundles of carbon fibers into flat sheets and impregnating the sheets with resin. Thanks to its light weight and exceptional strength, carbon-fiber-reinforced prepreg sheet is finding increasing applications in aircraft, spacecraft, and automobiles to improve fuel economy and reduce body weight, underscoring positive expectations for further demand growth in the years ahead. Molding and processing carbon-fiber-reinforced plastic (CFRP) composite materials, including prepreg sheets, typically have been time-consuming, and technologies that shorten molding times are seen as crucial to their wider use.

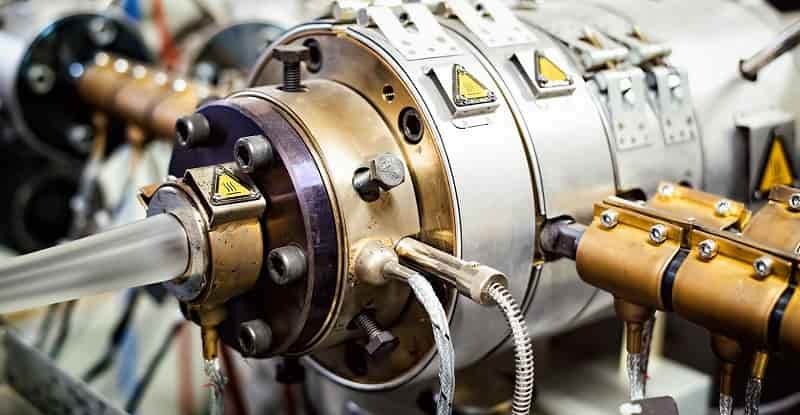

-Extrusion Basics: Mastering Material Changes and Shutdowns

Purge compounds can speed up material changes and reduce the amount of scrap. They are especially useful between runs of incompatible materials on large extruders.

Around the year 1900, cars and trucks began to share the road with horses and people. They usually kept to the right (or left in the British Empire, Japan, and Sweden), but there were no lights at intersections to stop the flow in one direction and allow flow in the other. That led to towers with traffic cops to keep order, more or less. Petrochemicals Carbon Fiber Prepreg

The first stoplights in the US — some say the world — went up in Cleveland in 1912, but I remember the unique ones on New York’s 5th Avenue crowned by a likeness of Mercury, designed by Joseph H. Freedlander in 1929 and in use until 1964.

Mercury is the Roman god of speed with winged feet — Hermes in Greek mythology. Mercury and bromine are the only elements that are liquid at room temperature. (Water is a compound, not an element.

-New generation of Biobased polyesters for durable products

Starch-based molecule called ISOIDIDE allows researchers to develop a new generation of polymer that can be used not only in BPA(Bisphenol A)-free packaging but also in engineering applications

Biobased products are gradually claiming their share in everyday products like packaging already, and now we want to develop polymers for the high-performance market as well. Petrochemicals Carbon Fiber Prepreg

Using Archer Daniels Midland’s rigid starch-based molecule called ISOIDIDE, we are developing a new generation of polymer materials that can be used not only in BPA(Bisphenol A)-free packaging but also in engineering applications such as automotive and electronics.

Researching together with industrial partners

These Biobased, yet strong and thermally resistant materials, show great versatility, which will be demonstrated by project partners of Wageningen Food & Biobased Research: Refresco is interested to explore the potential of HIPPSTAR materials for bottles, Beckers will use them as metal coatings, while HollandColours will use them in their colorants formulations. Working together with important industrial partners is the best way to develop polymers that meet the requirements and standards of the market.

-Pact Group and partners plan to build PET recycling facility in Australia

Pact Group, Cleanaway, Asahi Beverages and Coca-Cola Europacific Partners (CCEP) have partnered to develop a polyethylene terephthalate (PET) recycling facility in Australia. Petrochemicals Carbon Fiber Prepreg

The industry partners have signed a memorandum of understanding (MOU) to create a joint venture to build the proposed plant.

The recycling facility will process raw plastic materials collected through Container Deposit Schemes and kerbside recycling.

It will feature advanced sorting, washing, decontamination and extrusion technology and have the capacity to process around one billion bottles a year.

The plant will manufacture more than 20,000t of new recycled PET bottles and food packaging.

Pact will run the facility once it is operational and provide technical and packaging expertise, while Cleanaway will provide available PET through its collection and sorting network.

-Clyde plant to expanded production of recycled plastic

A new expansion project will allow a Clyde manufacturing plant to more than double its ability to recycle plastic for food and beverage containers.

The expansion at Evergreen, a plastics reclaimer and recycled polyethylene terephthalate (rPET) manufacturing facility, is being aided by a $5 million loan. Half is from the American Beverage Association in partnership with Closed Loop Partners and the other half from Closed Loop Partners’ Infrastructure Fund.

The expansion project will cost between $22 million and $24 million and will expand the plant’s ability to produce food-grade recycled plastic for containers from about 40 million pounds a year to a little more than 80 million pounds, said Gregory Johnson, vice president of operations for Greenbridge, the plant’s parent company.

Johnson said the Evergreen plant, located in east Clyde just east of downtown, currently employs 120 people. Nine new jobs are expected to be added as a result of the expansion, he said. Petrochemicals Carbon Fiber Prepreg

The current facility has 240,000 square feet and 54,000 square feet will be added, Johnson said.

-The Chemical Content of Recycled Products

Recycled materials are found in an increasing number of consumer products. What substances are contained in recycled products is generally not known. Therefore, Kristin K. Isaacs, U.S. Environmental Protection Agency, Research Triangle Park, NC, USA, and colleagues studied 210 household items made from either recycled or virgin materials. They used a suspect screening analysis with two-dimensional gas chromatography-time-of-flight mass spectrometry (GC × GC-TOFMS). Chemicals present in the products were tentatively identified using a standard spectral library or confirmed using chemical standards. Petrochemicals Carbon Fiber Prepreg

A total of 918 probable chemical structures (of which 112 were confirmed) were identified in recycled materials, and 587 (110 confirmed) in new materials. The identified chemicals were grouped based on their chemical structure classes, known or predicted functional role, and reported use in commerce. Hierarchical cluster analysis was then used to identify unique groups of chemicals that co-occur in subgroups of products. In addition, the commercial uses of the chemicals within the clusters were examined to provide evidence of the source and thus the potential exposure pathway. Screening-level risk metrics (useful for prioritizing chemicals for further investigation) were calculated for each identified chemical using abundance and detection frequency results along with available high-throughput exposure and bioactivity information.

Petrochemicals Carbon Fiber Prepreg