Petrochemicals Hydrogen Cotton Yarn 24-08-2021 - Arhive

Petrochemicals Hydrogen Cotton Yarn

Crude Oil Prices Trend

-Aquapak innovation maximizes fibre recovery rates critical to meeting circular economy

New research conducted by Aquapak Polymers highlights that recycle-ready adhesives and fully soluble barriers can replace plastics in fibre-based packaging, making it fully recyclable in high volume recycling mills. Based on the research, Aquapak has developed a novel biodegradable, non-toxic and water-soluble polymer called Hydropol which is three times stronger than alternatives and is designed to be used in existing thermo-processing equipment, giving it a wider range of applications.

According to the company, Hydropol enables up to 100 percent paper/board recovery whatever the percentage packaging makeup.The new technology is non-toxic, marine safe, dissolve and subsequently biodegrades, but still provides the much-needed functionality required for food, drink and household product packaging.

-NPP POLYPLASTIC plans to launch two compounding lines in Engels

NPP POLYPLASTIC, the largest Russian manufacturer of thermoplastic composite materials, plans to commission two compounding lines in Engels this year, the company said.

Investments in equipment amounted to EUR3.3 mn euros (Rb286 mn). After reaching the design capacity by 2022, these lines will produce 20,000 tonnes of material per year in addition to the volume that is already being produced today, and in 2023 it is planned to build a plant in the Special Economic Zone (SEZ) of the Volga region.

The report notes that in August 2021, NPP POLYPLASTIC celebrates its 30th anniversary. The company has produced 2 mn tonnes of thermoplastic compounds in three decades.

Earlier it was reported that RPC “POLYPLASTIC” plans to increase the volume of exports several times in the near future.

NPP “POLYPLASTIC” plans to modernize 50% of production lines by 2025 in terms of automation of the control system and traceability of production process data.

-Chevron invests in waste-to-hydrogen and renewable synthetic fuel startup in northen California

Chevron and other partners said they are investing in a startup to build modular waste-to-green hydrogen and renewable synthetic fuel facilities in northern California with tentative plans to eventually grow worldwide, reported S&P Global.

The USD20 million investment in Wyoming-based Raven SR is focused on technology to develop combustion-free, green hydrogen for transportation that is cleaner than so-called blue hydrogen derived from natural gas.

Unlike alternative approaches to waste disposal, such as incineration or gasification, Raven touts a steam and carbon dioxide reformation process that does not involve any combustion, purportedly reducing emissions and producing more green hydrogen per ton of waste than competing processes.

The goal also is to utilize the technology to produce more synthetic liquid fuels, including diesel and jet fuel, as well as other additives and solvents, such as naphtha, and even some electricity via microturbines. Further decarbonizing the production of jet fuel is a key goal, Raven said, to help combat climate change.

Other project partners include New York-based Hyzon Motors, Japan’s Itochu Corp. and the Ascent Hydrogen Fund. Hyzon, which focuses on hydrogen fuel cell-powered commercial vehicles, and Raven plan to build up to 250 hydrogen production facilities worldwide.

But the first facilities with Chevron and the partners will be in the San Francisco area.

PetroChina Liaoyang Petrochemical Co Ltd , part of the Chinese petrochemical major – PetroChina, has successfully started up its new polypropylene (PP) plant this week, according to CommoPlast with reference to market sources.

Based in Liaoning City, Liaoyang Province, China, the new PP plant has a production capacity of 300,000 tons/year. Petrochemicals Hydrogen Cotton Yarn

A source closed to the company informed that they has achieved prime grade production since 5 pm, 18 August, 2021, hence the commercial run was officially started up.

As MRC reported previously, the construction of a new PP plant in Liaoning began in September, 2019, and was completed in early June, 2021.

-PolyOne rebrands as Avient following Clariant Masterbatch acquisition

PolyOne has rebranded to ‘Avient’ following the acquisition of the colour masterbatch businesses of Clariant and Clariant Chemicals India Ltd.

The entry into the agreement to acquire the Clariant Masterbatch business was originally announced in December 2019. The Clariant Masterbatch business includes 46 manufacturing operations and technology centres in 29 countries and approximately 3,500 employees, who will join Avient’s Colour, Additives and Inks segment.

Robert M. Patterson, Chairman, President and Chief Executive Officer of Avient, commented: “We proudly welcome our newest associates and valued customers from Clariant Masterbatch.

-A novel green technology to transform the single-use plastic market

The CSIR has developed a bioplastic technology for producing 100% biodegradable and compostable plastic. The technology enables single-use plastic products that, when they end up in landfills, bio-degrade within 180 days. The bioplastic products, when combined with organic waste, can turn into compost within 90 days, leaving no toxic residues.

The CSIR has developed a bioplastic technology for producing 100% biodegradable and compostable plastic. The technology enables single-use plastic products that, when they end up in landfills, bio-degrade within 180 days. The bioplastic products, when combined with organic waste, can turn into compost within 90 days, leaving no toxic residues.

Bioplastics are a relatively new field within the South African plastics industry. As a result, landfills overflow with plastic bags and products from the household waste removal process. The CSIR’s bioplastic is made from plant-based materials to ensure that the disposed plastic waste in landfills is transformed from the biobased polymer into organic fertiliser. The development is a significant milestone for the CSIR in working towards environmental sustainability and a green economy for South Africa.

“Our bioplastic technology is based on the use of biopolymers and agricultural waste by-products such as starch, cellulose and glycerol.

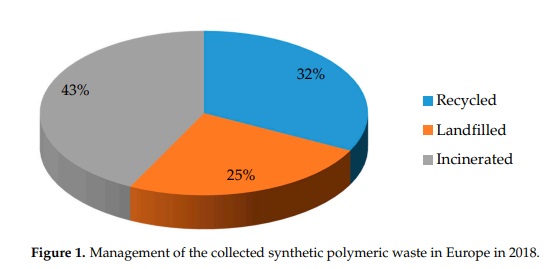

-Circulatory Management of Polymer Waste: Recycling into Fine Fibers and Their Applications

In modern society, it is impossible to imagine life without polymeric materials. However, managing the waste composed of these materials is one of the most significant environmental issues confronting us in the present day.

Recycling polymeric waste is the most important action currently available to reduce environmental impacts worldwide and is one of the most dynamic areas in indus[1]try today. Petrochemicals Hydrogen Cotton Yarn

Utilizing this waste could not only benefit the environment but also promote sustainable development and circular economy management.

In its program statement, the European Unionhas committed to support the use of sorted polymeric waste.

This study reviews recent attempts to recycle this waste and convert it by alternative technologies into fine, nano-, and microscale fibers using electrospinning, blowing, melt, or centrifugal spinning.

This review provides information regarding applying reprocessed fine fibers in various areas and a concrete approach to mitigate the threat of pollution caused by polymeric materials.

-How long will the rise of cotton yarn last?

ZCE cotton futures climbed up and broke through prior high after falling back in the end of Jul. Jan contracts once moved up to 18,500yuan/mt at the highest, nearly 1000yuan/mt higher from the low in early Aug. Cotton yarn paled facing the hot cotton. The offers of cotton yarn mills have increased by 500-1000yuan/mt, but they are hardly accepted by downstream buyers. The reason lies in the inconsistent anticipations of upstream and downstream in a sign that big differences exist in the fundamentals between cotton and cotton fabric which embarrasses the intermediate link cotton yarn. Petrochemicals Hydrogen Cotton Yarn

From the perspective of cotton, production reduction of new cotton and rush procurement of seed cotton seem to be inevitable and this anticipation generally recognized on the market boosts cotton price. Most players expect the price of new seed cotton over 8yuan/kg, even 10yuan/mt, about 24,000yuan/mt conversed into lint cotton price. Even if the specific price level is hard to tell, the ginners are highly possible to procure seed cotton in a rush and push up cotton price. CCFGroup also holds the bullish attitude to cotton price before Oct.

Oxo-biodegradable technology is an environmentally responsible solution for your plastic product, film, or packaging needs.

Products made with d2w biodegradable technology look and feel like conventional plastic. The difference is that if a bag or packaging made with d2w escapes collection and ends up as litter in the open environment, it will degrade and biodegrade in a continuous, irreversible and unstoppable process until there is nothing left. it biodegrades in the same way as nature’s wastes, without leaving toxic residues or microplastics behind. Petrochemicals Hydrogen Cotton Yarn

The d2w accelerates the natural process of oxidation until the product is no longer a plastic and has become a material which can be bio-assimilated (i.e. used as a food source) by bacteria and fungi on land or sea.

This has recently been confirmed beyond doubt by a 5-year study sponsored by the French government, called the Oxomar Project.

-Material shortages are forcing a supply chain rethink in automotive

Widespread shortages in range of materials used to make cars are impacting production but OEMs and suppliers are responding by accelerating the development of alternative closed-loop supply chains

Shortages in electronic components and semiconductors are costing OEMs dear in production and logistics. Losses in output are likely to impact overall new vehicle sales volumes as well. However, headlines around semiconductors and computer chips can miss the fact that many other commodities are currently in short supply, from leather and fabrics, to steel and rubber. Petrochemicals Hydrogen Cotton Yarn

These supply chain issues may not be shutting down production lines but they are likely to hit the bottom line of many manufacturers with significant price increases. That is leading to a serious rethinking of many current supply chains. OEMs are already making more use of control towers, asset tracking and other data, as well as digital tools to improve visibility of the supply chain. However, manufactures are also looking at changes in sourcing, including having additional supply options, or new alternatives altogether.

Petrochemicals Hydrogen Cotton Yarn