Petrochemicals Packaging Pollution 08-09-2021 - Arhive

Petrochemicals Packaging Pollution

Crude Oil Prices Trend

-60.Dornbirn-GFC 2021, 15. – 17. September, Online event

96 Lectures from Industry, Universities and Research Institutes, 20 Exhibitors and Break Out Sessions – guided by top class Keynotes

For 60 years the interest of the fiber industry in internationl exchange on future oriented innovations and their implementation has still been unbroken. Specialists of the fiber- and filament producers, the textile and nonwovens industry, the processing chain and the academic research support Dornbirn GFC with its technical and scientic presentations.

This year the Dornbirn Global Fiber Congress celebrates its 60th anniversary on one of the most modern interactive online platforms. Our partner ENRA offers outstanding networking tools and generates a virtual live experience (www.enra.app).

From 15. – 17. September the visitors have the possibility to select from 96 lectures.

2 virtual lecture halls form the platform for the presentation of the lectures in its usual high quality.

„See and be seen“ is the motto for the visitors in the meeting room “wonder.me“. With one click congress participants get into a conversation. As in Dornbirn itself, networking and the exchange of informations is the focus of the congress.

-RecyClass endorses films for HDPE recycling

In what Avery Dennison claims is a market first, RecyClass has approved products from the former’s film portfolio for complying with HDPE recycling guidelines. Label producers and brand owners across the home and personal care and food sectors will benefit from this, as Avery Dennison states that it can help them increase recycling rates.

Currently, RecyClass guidelines state that for packaging to be fully recyclable, the PE, machine direction oriented (MDO) or PP label must be removable through the ‘cold wash’ process, which uses water heated to 40 deg C. This is the most common method of recycling HDPE packaging in Europe, but labels that can be removed at this temperature can also come off during normal use, like when a shampoo bottle is taken in the shower.Petrochemicals Packaging Pollution

RecyClass approved Avery Dennison’s PE White, MDO White and PP Clear labels, which feature a permanent acrylic adhesive and remain in place during a cold wash, after extensive independent testing.

-The Story behind the Development of CELLIANT® Viscose presented at Dornbirn Global Conference

» World’s first in-fiber sustainable infrared viscose

Kelheim Fibres, the leading manufacturer of viscose specialty fibers, and Hologenix®, creators of CELLIANT®, a responsive textile using infrared technology, partnered to create CELLIANT® viscose, a unique combination of nature and performance. Dominik Mayer, Kelheim’s Project Manager for Fibre & Application Development, and Courtney OKeefe, Hologenix’s Chief Supply Officer, will share the story of how this first in-fiber sustainable solution on the market was developed. They will present at a webinar during the Dornbirn Global Fiber Conference Thursday, September 16, at 5:50 pm CEST.Petrochemicals Packaging Pollution

CELLIANT viscose in blends with cotton, regular viscose, MicroModal®, lyocell and wool offers a range of varieties. Among the many applications, it is ideal for performance wear, luxury loungewear, casual wear, bedding, towels and beauty.

CELLIANT viscose features natural, ethically sourced minerals embedded into plant-based fibers to create infrared products that capture and convert body heat into infrared, improving cellular oxygenation.

Kelheim’s flexible technology permits targeted interventions in the viscose fiber process and delivers this unique fiber that provides full functionality without the need for any additional processing steps, while impressing with a softer feel and cost and time savings compared to coated fabrics.

-Aramco opens new glass fiber facility in carbon-neutral move

Saudi Aramco has officially launched a new facility which will see a reduction in the use of steel rebar in its construction projects as part of a drive towards carbon neutrality in the Kingdom.

A new fibreglass production centre has been opened, with the material a non-corrosive alternative to steel, as well as offering twice the strength at a quarter of the weight. Petrochemicals Packaging Pollution

The non-metallic glass fiber-reinforced polymer (GFRP) rebar, will be produced at IKK Mateenbar’s 10,000 m2 facility, and is expected to reduce steel rebar consumption by approximately 50,000 tons per year.

Saudi Aramco has officially launched a new facility which will see a reduction in the use of steel rebar in its construction projects as part of a drive towards carbon neutrality in the Kingdom.

A new fibreglass production centre has been opened, with the material a non-corrosive alternative to steel, as well as offering twice the strength at a quarter of the weight.

The non-metallic glass fiber-reinforced polymer (GFRP) rebar, will be produced at IKK Mateenbar’s 10,000 m2 facility, and is expected to reduce steel rebar consumption by approximately 50,000 tons per year.

-LanzaTech and Twelve partnered to produce world’s first polypropylene from CO2

Twelve’s carbon transformation technology converts CO2 into materials that are traditionally made from fossil fuels Petrochemicals Packaging Pollution

Carbon transformation company Twelve and biotechnology company LanzaTech partnered to transform CO2 emissions into polypropylene, a key polymer used for medical devices including syringes and IV bags, as well as for large-scale applications in automotive, furniture, textiles and other everyday products.

Twelve’s carbon transformation technology converts CO2 into materials that are traditionally made from fossil fuels. The company helps brands eliminate emissions by replacing the petrochemicals in their products and supply chains with CO2Made® carbon negative chemicals and materials, as well as carbon neutral fuels.

LanzaTech’s carbon recycling Pollution To Products™ technology uses nature-based solutions to produce ethanol and other materials from waste carbon sources. The partnership will bring together the two platform technologies to enable additional product development from CO2 streams, representing just one of many pathways to scale carbon transformation solutions.

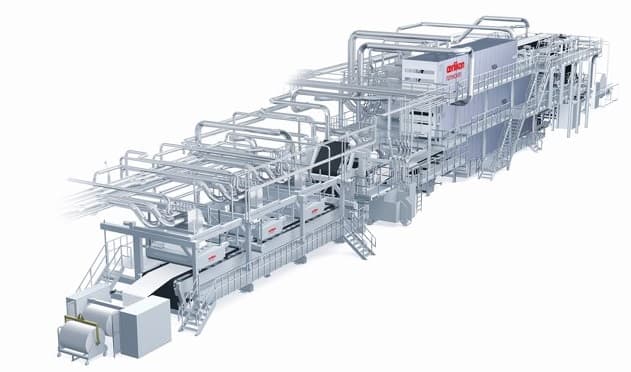

Oerlikon Nonwoven will showcase its wide range of nonwoven technologies at the INDEX 2020 exhibition in Geneva, Switzerland, from October 19-22.

Unique and highly-sophisticated nonwovens for filtration, insulation and sorption applications can be simply and efficiently manufactured with the company’s meltblown technology. Petrochemicals Packaging Pollution

The polymers used to produce the filter media and membranes are as diverse as their applications, ranging from classical polyolefins (PP, PE) as well as PET, PLA, PBT and PA, through to special plastics such as PPS and TPU.

The ecuTEC+ electro-charging unit electrostatically charges media in order to further increase filter efficiency. It distinguishes itself from other concepts with its extreme flexibility. Users can choose from numerous possible variations to set the optimum charge intensity for their respective filter applications.

-Next Horizons: Heimtextil presents the 2022/23 trends

International trade fair for home and contract textiles, 11 – 14 January 2022 to take place in Frankfurt/Main Petrochemicals Packaging Pollution

Three international design agencies form the Heimtextil Trend Council. Together, they develop a well-founded global vision of the coming interior trends. Alongside the Heimtextil Trend Council, Heimtextil management has established a trend forecast for the coming season and presented it live via an online conference on 1 September 2021 from Frankfurt am Main. Trend Council members Anja Bisgaard Gaede from SPOTT trends & business from Denmark who is directing all trend activities this season, Anne Marie Commandeur from Stiljinstituut Amsterdam and Kate Franklin and Caroline Till from London studio FranklinTill shared their insights into the future of the industry. Designers, interior architects and decorators get inspired by the design forecast for the new season.

Next Horizons: long-term and circular mindset

The Next Horizons are not a fixed goal or a finish line – they are mindsets. These are made up of long-term thinking, accepting that the best way to impact the world is simply not to. Paradoxically, we have begun our transition to sustainability by addressing the problems within our manufactured system instead of transforming our approach to not create waste or imbalance. Transforming our nexus begins with accepting our economies are embedded within nature.

-India to become first Asian country to launch a Plastics Pact

September 06, 2021 | Global themes | UKRI | Swindon, Wiltshire | United Kingdom

India has become the first Asian country to develop a plastics pact, launching a ground-breaking new initiative to bring together leading businesses at a national level to make commitments for building a circular system for plastics.

The India Plastics Pact (IPP) has launched as a collaboration between:

- WWF India

- the Confederation of Indian Industry (CII).

The pact is supported by UK Research and Innovation (UKRI) and WRAP, and endorsed by the British High Commission in India.

In Autumn 2020, UKRI committed £250,000 of funding to:

- enable WRAP to establish the India Plastics Pact

- initiate start-up

- engage the Indian government

- develop the appropriate targets and priority work streams for India.

Launching the pact

The pact was formally announced on 3 September, at the CII 16th Sustainability Summit. Professor Sir Duncan Wingham, Executive Chair of NERC spoke at the event alongside Alex Ellis, the British High Commissioner to India who was the keynote speaker.Petrochemicals Packaging Pollution

-Towards a circularity in recycling of mattresses

After an average of ten years most mattresses today are thrown away, thus squandering resources and creating high quantities of waste. At the same time, valuable raw materials are needed to manufacture new soft foam mattresses – above all crude oil. A circular economy solution for mattresses can therefore both reduce waste and save fossil resources. Petrochemicals Packaging Pollution

At BASF, we are continuously looking at ways to reuse and re-enter waste into product lifecycles and to foster circular economy solutions. With the circular economy concept BASF aims to decouple economic growth from the use of finite resources and is accelerating the adoption of these principles into our day-to-day operations. BASF offers a solution to finally closing the loop for polyurethane soft foam with the chemical recycling of mattresses.

-Social cost of plastic pollution more than GDP of India

The pollution, emissions and clean-up costs of plastic produced in 2019 alone could be $3.7 trillion, according to a report released Monday (6 September) by wildlife charity WWF, warning of the environmental and economic burden of this “seemingly cheap” material. Petrochemicals Packaging Pollution

There is increasing international alarm over the sheer volumes of fossil-fuel based plastics entering the environment, as microplastics have infiltrated even the most remote and otherwise pristine regions of the planet.

In its report, WWF said societies were “unknowingly subsiding” plastic, with their estimates for the lifetime costs of 2019 production equivalent to more than the gross domestic product of India.

Petrochemicals Packaging Pollution