Petrochemicals PETBottle BioFilm 19-04-2021 - Arhive

Petrochemicals PETBottle BioFilm

Petrochemicals Naphtha R-POYPolyester Trend

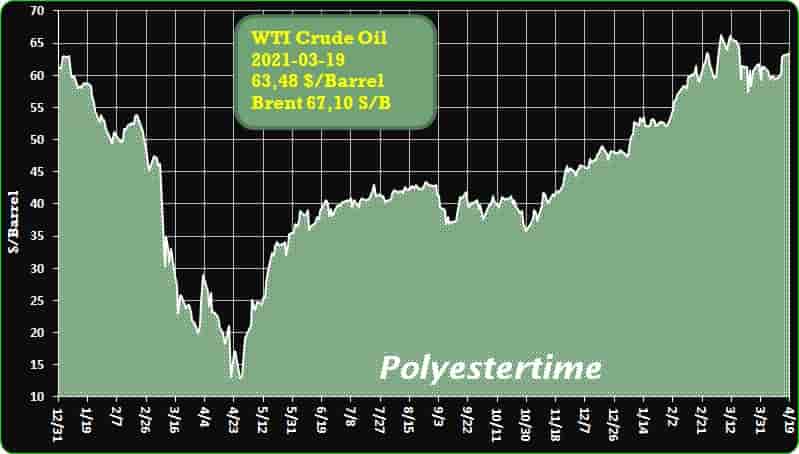

Crude Oil Prices Trend

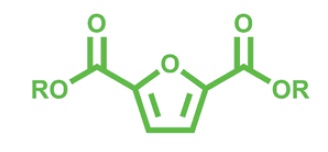

-PEF can become the ‘standard in the food and drink industry’, says plastics producer

The use of PEF plastic – which is made entirely from plants, is fully recyclable and which degrades in nature much faster than normal plastics — has the potential to become the standard in the food and drink industry, claims the company attempting to scale up the material. Petrochemicals PETBottle BioFilm

Dutch biochemical company Avantium says it is on track to open its first commercial production plant by the end of 2023. The facility – in Delfzijl, the Netherlands, will produce 5,000 metric tonnes of FDCA per annum. FDCA is the key building block for polyethylene furanoate (PEF), a 100% plant-based, fully recyclable biopolyester. According to Avantium, PEF has the potential to replace various packaging materials such as PET, glass or aluminium in typical applications like bottles for soft drinks, water, alcoholic beverages and fruit juices. It expects bottles made with PEF to appear in Europe’s supermarkets by the beginning of 2024.

The Euronext Amsterdam-listed company’s plans have been boosted after it raised around €28 million by issuing 5.2 million new shares and announced a deal with Belgium-based plastic packaging supplier Resilux for the supply of a fixed volume of PEF resin from the Avantium plant.

It has also signed collaboration agreements to develop sustainable bottles with an undisclosed ‘major global food and beverage brand owner’, the Japanese specialty chemical company Toyobo, the US specialty polyester film producer Terphane, and the Dutch beverage bottling company Refresco.

-ADNOC seeks hydrogen ventures with India

The Abu Dhabi National Oil Company (ADNOC) wants to explore hydrogen opportunities with India’s public and private sectors to cater to growing demand for energy and for cleaner fuels, the group’s managing director and CEO said on Thursday. Petrochemicals PETBottle BioFilm

Dr. Sultan Ahmed Al Jaber, who is also the UAE’s minister of industry and advanced technology, revealed ADNOC produces about 300,000 tonnes/year of hydrogen a year as part of its current industrial processes.

The company’s existing infrastructure and commercial-scale Carbon Capture Utilisation Storage (CCUS) capabilities should help it become a major player in the developing blue hydrogen market, the senior executive explained.

Adnoc is also exploring the potential of green hydrogen through the Abu Dhabi Hydrogen Alliance which was recently established by the company and other partners.

-Coveris stretch films project nears completion

Coveris is close to completing a £6 million ($8.3m) machine and infrastructure upgrade at its stretch films facility in Winsford, UK.

In a year-long project, site capacity has been increased by over 25 per cent to meet growing market requirements for recyclable and recycled performance films, the flexible packaging converter said. Petrochemicals PETBottle BioFilm

Improvements include the construction of an 825 sq m film hall, and the installation of four new co-extrusion lines, acquired from the former Total Polyfilm business.

Among the products developed at Winsford are the company’s latest 11-micron stretch film, and a 5-micron pre-stretch and hybrid cast replacement Blast film.

The project completes when the site’s technical development capabilities are further enhanced with “next generation assets”, Coveris said.

According to the company, the plant was now a “centre of excellence” for industrial, agri and recycled stretch products, positioned alongside its Kufstein facility in Austria.

-Weak Demand, China PET Supply and Demand Deadlock, Up and Down Dilemma

According to the data monitored by SunSirs, as of April 14, the quotation of PET water bottle manufacturers was 7,050.00 RMB/ ton, and the market focus of PET bottle chips declined, which was 1.63% lower than that of the same period last month. Petrochemicals PETBottle BioFilm

The overall market transaction atmosphere was cold.

PET market price is stable but weak, some factories slightly reduce 50-100 RMB/ ton, downstream demand is insufficient, the number of new orders is limited, upstream price is up in a narrow range, pet cost support is general, compared with the same period last week, PET price decreased 1.63%, or 110 RMB/ ton, inventory consumption is slow, supply and demand is stalemate.

-Packaging Matters and Origin Materials announce partnership

US-based carbon-negative materials company Origin Materials has partnered with packaging company Packaging Matters to develop advanced packaging materials. In the partnership’s initial stage, Origin Materials will produce sustainable furandicarboxylic acid (FDCA), a chemical used to make the next-generation polymer polyethylene furanoate (PEF). Petrochemicals PETBottle BioFilm

The PEF will support the development of novel polymers to fulfil both customer and consumer requirements, primarily being used to make products for fresh fruit, vegetables and salad.

Packaging Matters founder and CEO Chuck Buff said: “By partnering with Origin Materials and purchasing sustainable carbon-negative PET, we are one step closer to achieving our goal of delivering a carbon-neutral solution that drops in seamlessly to the existing recycling infrastructure. By replacing petroleum-based PET with Origin Materials’ sustainable carbon-negative PET and PEF, we aim to create new, better-performing products, with competitive and more stable pricing.

-PVC Plasticizers Based on Renewable and Chemically Recycled Feedstock

BASF’s new biomass balance BMB and chemically recycled Ccycled now part of the company’s portfolio of plasticizers. Petrochemicals PETBottle BioFilm

A portfolio of PVC plasticizers from BASF also contains versions based on renewable or chemically recycled feedstock, Said to have the same specifications and technical properties as those of conventional fossil fuel plasticizers, the alternative feedstock for these plasticizers is allocated to the sales products according to a mass balance approach. The products include:

▪ BMB, biomass balanced plasticizers, including Hexamoll DINCH BMB, Palatinol N BMB, Palatinol 10-P BMB and Plastomol DOA BMB, are produced with bio-naphtha or biogas. These materials are derived from organic waste or vegetable oils. Biomass balanced plasticizers have a lower carbon footprint than the conventional ones and help save fossil resources. Both, BASF’s mass balance approach and BMB plasticizers are certified according to REDcert2 .

-Armacell and METYX pursue joint business opportunities turkey

Armacell, a global leader in flexible foam for the equipment insulation market and a leading provider of engineered foams, pursues discussions with METYX, a Turkey-based manufacturer of high-performance technical textiles, to jointly serve the Turkish composite manufacturing market. Petrochemicals PETBottle BioFilm

Strengthening Armacell’s position in the Turkish composite industry

PET-based foam core kitting operations for wind turbine manufacturing

Armacell’s 7th global PET foaming line to be installed in Turkey

The collaboration will provide the local production of Armacell’s PET-based foam products supply to METYX’s core kitting operations and distribution. Armacell has a long expertise in developing and manufacturing innovative and environmentally friendly PET foam solutions, and METYX is excelling in the production of high-performance technical fabric products.

-Palmolive Unveils 100% Post-Consumer Recycled Plastic Bottles in Drive toward Circular Economy

Palmolive is relaunching its Palmolive Ultra dish soap in bottles now made with 100% post-consumer recycled (PCR) plastic. The company says the move will divert more than 5,200 tons of plastic a year from landfills in the US and Canada and help the company in its drive to achieve a circular economy.

The company says it is the biggest dish soap brand in North America to transition to 100% PCR bottles. Petrochemicals PETBottle BioFilm

Palmolive is made at a Colgate-Palmolive facility in Cambridge, Ohio, that has achieved TRUE Zero Waste certification from Green Business Certification Inc. The new PCR Palmolive Ultra bottles feature labels that highlight the brand’s use of recycled plastic, 100% ingredient transparency, and a How2Recycle logo, which communicates recycling instructions so shoppers can properly recycle the bottles at home and help stimulate the circular economy.

The packaging transition will contribute to Colgate-Palmolive’s commitment to design and deliver zero plastic waste solutions for all products, including eliminating one third of its new plastics by 2025, the company says.

-Europe April R-PET prices firm on tight supply, strong demand

Senior editor for recycling, Matt Tudball, looks at the drivers behind this week’s recycled polyethylene terephthalate (R-PET) price increases, discussing:

- price rises across all three products; Petrochemicals PETBottle BioFilm

- major concern on post-consumer bottle availability; and

- uncertain outlook for summer PET bottle demand.

Petrochemicals PETBottle BioFilm