Petrochemicals PETBottle GeneralNews 22-04-2021 - Arhive

Petrochemicals PETBottle GeneralNews

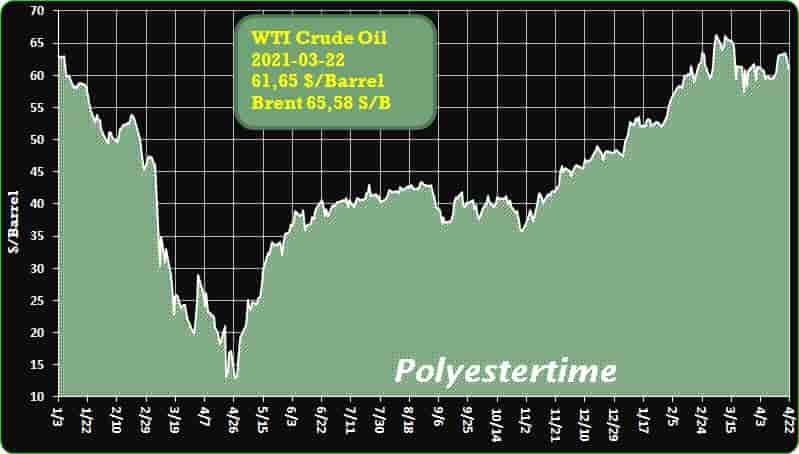

Crude Oil Prices Trend

-Dow, Lucro and Marico join forces to advance circular packaging solutions in India

Dow and Lucro Plastecycle, a homegrown Indian recycling company, welcome Marico Limited, one of India’s leading consumer goods companies into a tripartite partnership to introduce Dow’s PCR-based coalition shrink films into its line of consumer products. This alliance enables Dow to work towards meeting its new sustainability target of stopping waste by collecting 1 MMT of plastics to be collected, reused or recycled by 2030.

Earlier this year, Dow and Lucro signed a memorandum of understanding (MoU) to develop and launch polyethylene (PE) film solutions. Under the MoU, Dow will utilize its industry leading team of packaging experts, material scientists, recycling equipment, blown film manufacturing and testing capabilities at Pack Studios Shanghai and Mumbai to help Lucro develop recycled film for various applications.

With the addition of Marico Limited, this tripartite partnership forms part of Dow’s comprehensive strategy to enable a circular economy for plastics by focusing on integrating recycled content into product offerings ensuring that product’s values are maximized and extended across its lifecycle from creation to use to disposal.

Pilot plant to be built next year in the U.K. using Recycling Technologies’ depolymerization solution.

Germany’s Ineos Styrolytion (U.S. office Aurora, Ill.), Trinseo, Berwyn, Penn. and Recycling Technologies of the U.K., have reached a significant milestone in their plans to built commercial recycling plants in Europe that will use Recycling Technologies’ depolymerization process.

These three companies all share the same vision of making PS a circular material through depolymerization. The unique properties of PS reportedly allow for full circularity where PS waste is returned to its chemical building blocks before being polymerized again. Properties of the resultant recycled PS will be identical to those of virgin PS. Life cycle assessment calculations show significant decreases in greenhouse gas emissions when compared with PS production from naphtha.

-Green tie-ups: AmSty/Agilyx on to 2nd jv PS facility in US

AmSty, the largest polystyrene (PS) producer in the Americas, and recycler Agilyx Corporation, a wholly owned subsidiary of Agilyx AS, are to explore the development of a jointly owned advanced recycling facility. The initial scope of this project will be a 50 to 100 tonnes/day advanced recycling facility located at AmSty’s Styrene production facility in St. James, Louisiana. The facility will be a next generation expansion of Agilyx advanced recycling technology already in use at the parties’ Regenyx joint venture operating in Tigard, Oregon, where post-use PS products are converted back into virgin-equivalent styrene monomer. A feasibility study for the project is under way, with a timeline for construction and commissioning to be announced as progress continues.

Feedstock for this collaboration would be accessed via Cyclyx, Agilyx’s feedstock management company. AmSty is a founding member of the Cyclyx consortium. The Cyclyx platform encompasses an integrated set of innovations including chemical characterization of plastics, predictive modelling of feed sources to product pathways, custom feedstock recipes, and customized supply chains to deliver waste plastic feedstocks appropriate for recycling pathways.

-ExxonMobil plans to raise PE prices in the US in May

ExxonMobil, the largest privately-owned US petrochemical company, raised its May polyethylene (PE) prices by 6 cents a pound (USD132 a tonne) in the US market, the company said in a letter to customers.

The letter added that the company will also implement the previously announced April increase in LDL and LDPE prices by 9 cents per pound (USD198 per tonne), and HDPE prices by 7 cents per pound (USD154 per tonne).

Polyethylene demand remains strong in the United States as a series of changes in consumer behavior caused by the pandemic, including an increase in home dining and an increase in online shopping, have boosted demand for polyethylene packaging products.

According to ScanPlastAccording to the results of the first two months of the current year, according to the results of the first two months of the current year, which is 9% less than in the same period a year earlier, according to Market report company, the estimated consumption of PE in Russia was 356.37 thousand tons. The supply of high-density polyethylene (LDPE) only increased.

-Amcor invests in US-based flexible packaging firm

Switzerland-based consumer packaging company Amcor has invested around $10mn-15mn in US-based Epac Flexible Packaging, as part of efforts to achieve its 2025 sustainability goals.

The US firm produces food-safe pouches and films for items such as snacks, and frozen and microwaveable products. Its packaging films are made from polyethylene terephthalate (PET), polyethylene (PE) or biaxially oriented polypropylene (BOPP).

PE and polypropylene (PP) are widely used in the packaging of food items. But an increasing shift towards sustainable packaging among producers and downstream converters because of environmental pressure to limit single-use plastics has led to the development of recyclable PE and PP for food.

-BASF, QUANTAFUEL AND REMONDIS TO COOPERATE ON CHEMICAL RECYCLING OF PLASTIC WASTE

BASF SE (Ludwigshafen, Germany), Quantafuel ASA (Oslo, Norway) and Remondis SE & Co. KG (Lünen, Germany) have signed a memorandum of understanding (MoU) to jointly evaluate a cooperation in chemical recycling including a joint investment into a pyrolysis plant for plastic waste. It is intended that Remondis, one of the world’s leading waste and water management companies, supplies suitable plastic waste to the plant, and BASF uses the resulting pyrolysis oil as feedstock in its production Verbund as part of its ChemCycling project. Quantafuel intends to provide the technology and to operate the plant. The company is a specialist for the pyrolysis of mixed plastic waste and the purification of the resulting pyrolysis oil; the technology is jointly developed and being held with BASF. The location of the pyrolysis plant will be evaluated together.

Each year, almost 20 million metric tons (m.t.) of plastic waste in Europe go unrecycled. By establishing chemical recycling as a complementary solution to mechanical recycling it is possible to bring back more plastic waste into the materials cycle, which would otherwise be incinerated. The pyrolysis technology can be used to process plastic waste streams that are not recycled mechanically, e.g. for technological or economic reasons.

-Sabic To Raise PC And ABS Prices In The US In May

Saudi Saudi Basic Industries Corporation (Sabic), one of the world’s largest petrochemical producers, intends to raise the prices of acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) in the United States from May 17, according to the company’s letter to customers …

The proposed increase for PC and ABS is 34 cents per pound (USD750 per tonne). The company cited the current dynamics of supply and demand as the reason for the rise in prices.

Earlier it was reported that in January Saudi increased the prices of PC brand LEXAN by 20 cents per kg (USD198 per ton), PC compound and ABS brand CYCOLOY by 20 cents per kg (USD198 per ton), ABS brand CYCOLAC by 20 cents per kg (USD198 per ton), PC brand GELOY ASA by 20 cents per kg (USD198 per ton).

According toScanPlastu by MRC, the total estimated consumption of PC granulate in the Russian market (excluding imports and exports to Belarus) increased by 27% in January-February 2021 and amounted to about 16.0 thousand tons against 12.6 thousand tons a year earlier.

-Starlinger viscotec celebrates 2 Million tons of installed recycling capacity worldwide

In spring 2021 viscotec, a division of the Austrian machinery supplier Starlinger & Co GmbH, reached a milestone: an impressive 2 million tons of capacity are available for the production of PET recyclate on viscotec systems worldwide.

To take a look at the recycling quantities in Europe helps to put this number in relation. An estimated 4.3 million tons of PET packaging waste is generated annually in the European Union and around half is actually sorted for recycling.(1) With the capacity installed by Starlinger viscotec, almost the entire amount of collected and sorted PET packaging waste in the European Union could be processed to produce recycled PET (rPET).

-Durable, repairable and mainstream – How ecodesign can make our textiles circular

Executive summary

Textile products have a tremendous ecological footprint at all stages of their lives. As more clothes are produced, consumed, and thrown away than ever before, the current linear, take-make-dispose model followed by the textile

industry is putting an enormous pressure on our planet – its resources, environment and climate.

Durable, repairable and mainstream – how ecodesign can make our textiles circular

In spite of its shocking impact, the sector has been largely untouched by EU environmental policies to date. However, the tide seems to be turning: at the end of 2019, the European Commission finally noticed the potential of

circular models in the textile sector4.

An EU Strategy for Sustainable Textiles under the Circular Economy Action Plan was identified as a priority of the Commission’s European Green Deal5, alongside a Sustainable Products Policy, and a

‘zero-pollution’ ambition for a toxic-free environment.

-Amcor: More sustainable packaging delivers added, measurable benefits with PCR content

Bottled beverage producer seeks added sustainability benefits without compromising the run speeds and machinability necessary to their efficiency and profitability. Solution: AmPrima™ plus 30% PCR content.

With brands increasing their focus on 2025 sustainability pledges, exploring additional sustainability options is becoming increasingly central to meeting their goals. Many bottled beverage producers have smartly chosen Amcor’s AmPrima™ recycle ready polyethylene (PE) shrink film over corrugate and paperboard because it uses less energy and lowers greenhouse emissions in the distribution channel, without compromising run speeds and machinability. PE shrink is one of the most recycled types of plastic films in the U.S., collected through the 18,000 in-store drop-off locations in North America or curbside where available (1).

By expanding efforts to close the loop on a circular economy – with post-consumer recycled (PCR) content – additional sustainability benefits can be achieved while providing the same versatility and performance as standard PE shrink films.

-Lenzing Taps Supply Chain Leaders to Launch Tencel Lyocell Hemp Denim

Debuting at Kingpins24, the Bast Recast collection demonstrates the power of collaboration, featuring a Tencel lyocell hemp blend and environmentally friendly solutions from leaders throughout the denim supply chain that underscore hemp’s sustainable properties.

“In order to pay homage to the history of hemp, we brought together a group of companies who we knew could deliver both the quality, innovation and environmental integrity that the sustainable denim wardrobe projects demand,” said Michael Kininmonth, project manager at Lenzing.

The range includes GOTS-certified conventional and cottonized hemp fibers and yarns supplied by Kingdom, one of the world’s largest linen yarn and hemp yarn manufacturers. All fabrics were developed exclusively in-house by Pakistan-based denim producer Naveena Denim Ltd., and U.K.-based Endrime designed, pattern cut and sewed the entire collection, using hemp’s centuries-long history as inspiration.

Petrochemicals PETBottle GeneralNews