Petrochemicals Polyamide CarbonFiber PP 24-07-2020 - Arhive

Petrochemicals Polyamide CarbonFiber PP

Crude Oil Prices Trend

-Project XYZ supplies second life to Alabama injection molding plant

Huntsville Ala.-based operating company Project XYZ finalized its purchase of a CBC INGS America injection molding plant in Muscle Shoals Ala., after the subsidiary of Tokyo-based CBC Group notified the Shoals Economic Development Authority it would cease operations in the area in late January.

SEDA contacted Kim and Larry Lewis, owners of Project XYZ, which had other projects in the area, to see if they were interested in purchasing the facility, Larry Lewis told Plastics News.

-What the oil crash means for bioplastics

Bioplastics, plastics made from a biological feedstock, could be a renewable and more sustainable alternative to fossil-based plastics.

Unlike the vast majority of fossil-based plastics, many bioplastics are biodegradable, which could help provide a solution to the dizzying escalation in plastic waste seen across much of the world. Petrochemicals Polyamide CarbonFiber PP

Although bioplastics have historically struggled to deliver the same performance as fossil-based plastics, technology is increasingly closing the gap, creating highly functional plastics that do not cost the Earth.

-Japan faces up to its plastic problem

At the beginning of this month, I walked into a bakery with a reusable shopping bag and the best of intentions. I was ready to do my bit for the environment as Japanese stores finally began to charge a tiny fee for disposable plastic bags.

But even before I paid, it all felt rather futile. Petrochemicals Polyamide CarbonFiber PP

The pastries I selected were individually wrapped in plastic bags; the cashier, standing in front of a plastic curtain, wore a plastic face shield. By the time I returned home, UberEats had delivered my dumplings in a plastic lunchbox wrapped in a plastic bag.

-A straightforward explanation of biodegradable vs. compostable vs. oxo-degradable plastics

As consumer demand for sustainable products grows, bioplastics —which can reduce our reliance on fossil fuels and decrease greenhouse emissions— will become more prevalent. Production of bioplastics is expected to grow by as much as 20% by 2022, and as it does, consumer understanding of bioplastics will need to grow with it.

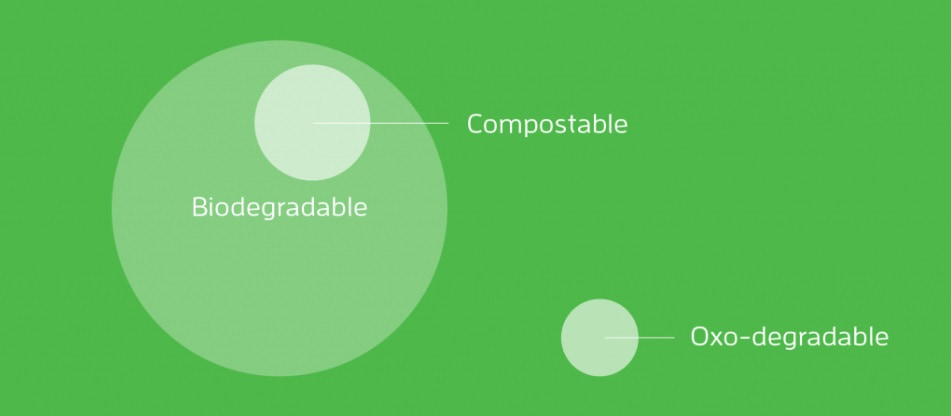

A major source of confusion is the difference between three terms: Biodegradability, compostability and oxo-degradability. Although these terms are often used interchangeably, they are not synonymous. Confusion regarding common bioplastics terminology such as these, especially where it concerns the disposal of bioplastic products, can have dire consequences. Petrochemicals Polyamide CarbonFiber PP

Companies need to understand the distinctions between each category in order to accurately and honestly market their products. And consumers need to understand these terms in order to make educated purchasing decisions and properly dispose of bioplastic products at the end of use.

-New HDPE material from the ML Polyolefins

ML Polyolefins has developed a new HDPE blend to meet expectations of the growing and demanding recycling field. The regranulate manufacturer has developed a unique blend for extrusion which is characterised by high stability of technical parameters and repeatability. Petrochemicals Polyamide CarbonFiber PP

Product PIPEFIN HD46 – this is the actual name of this material used in the ML portfolio and this product is introduced as another premiere in the time of celebration for 20th anniversary of the company. This time ML has developed a material dedicated to processing, where quality and specific technical requirements are extremely important: – We have been working in our R&D department for a long time on new recipes to meet customer needs. Most of the popular recycling companies on the market create universal products ignoring important specifications of various production processes and materials requirements.

-Stora Enso and Cordenka joined forces to develop precursor for bio-based carbon fiber

Stora Enso and Cordenka, the leading producer of premium quality industrial rayon based in Germany, are developing precursors for bio-based carbon fiber, both driven by the need for high performance carbon fiber in transportation, construction and power generation.

Stora Enso has been developing the technology for manufacturing carbon fiber from wood-based raw materials, i.e. dissolving pulp and lignin, at laboratory scale.

The partnership with German company Cordenka GmbH aims at upscaling the precursor development process to pilot-scale operation. Petrochemicals Polyamide CarbonFiber PP

The precursor development is carried out with specialised manufacturing spinning equipment at Cordenka’s Obernburg production site in Germany.

The venture is supported by BMC, owner of Cordenka, as part of their strategy to extend the reach of Cordenka into new growth markets and Asia.

-Carbon fiber qualified for Airbus

Teijin Limited says that its Tenax dry reinforcements (DR) carbon fiber material is now qualified to produce Airbus A320neo wing spoilers using resin transfer molding (RTM).

The automated RTM process can now incorporate Tenax dry reinforcements non-crimp fabrics (DRNF) and dry reinforcements braided fibers (DRBF) to form skins and stiffeners while maintaining existing product interfaces, so that final spoiler components can be directly replaced, the company said. Petrochemicals Polyamide CarbonFiber PP

Teijin says that its Tenax DRNF materials are made of bundled carbon fiber filaments spread out in one direction in multiple layers with different directions, depending on the final component`s structural requirements, while Tenax DRBF can be applied within the spoiler component structure to act as cavity fillers. Both materials have been qualified individually by Airbus specifically for this application.

-1TcA launches face masks enhanced by HeiQ Viroblock tech

1TcA in collaboration with sustainability driven business Project Plan B, has launched the first British made reusable, sustainable and recyclable face masks and snoods manufactured using Global Recycle Standard (GRS) fabric woven from recycled waste plastic and treated with HeiQ Viroblock technology. The products are available immediately for procurement. Petrochemicals Polyamide CarbonFiber PP

1TcA was aware of the risk of face coverings acting as vectors for viruses and bacteria. Before, during and after use there is a risk of fabric contamination and the transfer of pathogens to and from the surface of the face masks: when putting them on and taking them off, during disposal and when touching the mask whilst wearing or during adjustment of the fit. The addition of HeiQ Viroblock technology makes the fabric resistant to harmful microbes.

HeiQ Viroblock is one of the first textile finishing technologies that have been successfully tested against the virus that causes the Covid-19 disease, SARS-CoV-2, in the laboratory, using the Viral Stability and Persistence test

-Covestro launches partially biobased polycarbonate film

Covestro has recently introduced a new polycarbonate (PC) film with more than half of its carbon content sourced from plant-based raw materials, reported Chemweek.

The partially biobased film, in which a portion of oil-based primary products are replaced by biomass material, will be the first in the company’s product portfolio and will reduce the film’s carbon dioxide (CO2) footprint by approximately 20%, it says. Increased use of alternative resources for in-house production is part of the company’s long-term strategic program as it “fully commits” to a circular economy, it adds.

The new film can be used in applications in the electrical, consumer, and automotive industries, as is typical for conventional PC films, Covestro says. Petrochemicals Polyamide CarbonFiber PP

-Macron calls for EU sanctions against Turkey amid Ankara-Athens tensions

“It is unacceptable that the maritime space of (EU) member states be violated and threatened. Those who are doing that must be sanctioned,” said the French leader.

Tensions sparked by Turkey’s intent to prepare for oil-and-gas drilling in the Eastern Mediterranean escalated Thursday, prompting France to call for European Union sanctions against Ankara and the Greek government to warn it will repel Turkish moves.

In response to plans by Turkey to proceed with an oil-and-gas exploration mission south of Greek islands in the Eastern Mediterranean, Greece said it will do “whatever is necessary” to defend its sovereign rights. Petrochemicals Polyamide CarbonFiber PP

The dispute over seabed mineral rights has led to increased navy deployments by both NATO members in the region, where a Turkish research vessel, the Oruc Reis, is being prepared for a survey mission.

-EU to introduce levy on non-recycled discarded plastic, VCI opposes the additional charge

The European Council decided, after a special meeting held on 21 July, to introduce a levy on non-recycled discarded plastic as part of the EU’s COVID-19 recovery plan, reported Chemweek. Petrochemicals Polyamide CarbonFiber PP

However, Germany’s chemical industry association VCI (Frankfurt) had, prior to the EU Council’s meeting, expressed opposition to the project because it adds a regulatory and cost burden rather than supporting packaging recyclability.

The EU Council says, “As a first step, a new own resource will be introduced and apply as of 1 January 2021 composed of a share of revenues from a national contribution calculated on the weight of nonrecycled plastic packaging waste with a call rate of EUR0.80 per kilogram with a mechanism to avoid an excessively regressive impact on national contributions.”

Petrochemicals Polyamide CarbonFiber PP

Petrochemicals Polyamide CarbonFiber PE 23-07-2020