Polymers Petrochemicals PET Resin 02-05-2019 - Arhive

Crude Oil Prices Trend

-Technology profile: polyethylene furanoate production

This column is based on “Polyethylene Furanoate Production — Cost Analysis,” a report published by Intratec. It can be found at: www.intratec.us/analysis/polyethylene-furanoate-production-cost.

Polyethylene furanoate (PEF) is a polymer synthesized from the copolymerization of 2,5-furandicarboxylic acid (FDCA) with monoethylene glycol (MEG). Since both monomers can be obtained from biomass starting material, and the resulting PEF is 100% recyclable, PEF is considered a bio-based analogue to polyethylene terephthalate (PET). Also, PEF production is thought to have the potential to reduce greenhouse gas emissions compared to the production of PET.

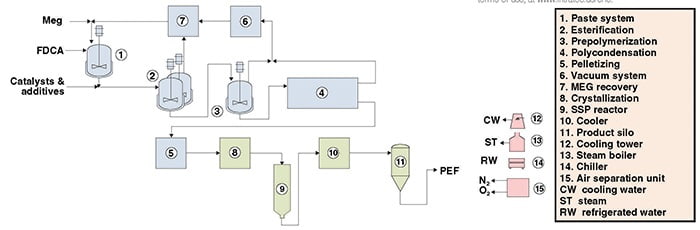

Strong parallels are reported in the literature between the production of PET and PEF, to the point that existing PET assets may be used for PEF production. FDCA and MEG are polymerized in two steps (Figure 1) yielding bottle-grade PEF.

Melt-phase polymerization. MEG and FDCA are initially fed to the paste system, which prepares a uniform feed slurry batch-wise for melt-polymerization downstream. The mixture then passes through two agitated and jacketed reactors, in which esterification takes place, generating bis(2-hydroxyethyl)-2,5-furandicarboxylate (BHEF). Small amounts of water formed are removed, as well as the excess unreacted ethylene glycol that is boiled off and directed to the MEG recovery system.

-Sustainability a major topic at Techtextil and Texprocess

In 2017 Techtextil and Texprocess welcomed over 47,500 visitors. © Messe Frankfurt Exhibition GmbH / Jean-Luc Valentin

In 2017 Techtextil and Texprocess welcomed over 47,500 visitors. © Messe Frankfurt Exhibition GmbH / Jean-Luc Valentin

Sustainability at Techtextil and Sustainability at Texprocess are the two topics by which these leading international trade fairs for technical textiles and nonwovens, and for the processing of textile and flexible materials, will be explicitly turning their focus for the first time onto their exhibitors’ approaches to sustainability. To this will be added a broad complementary programme on this topic. Among those contributing will be major players in the industry, such as Kering, Lenzing and Zalando.

-Plastics dominate new online rigid containers marketplace

Out with the old, in with the new. That’s the intent of Denver-based Dempsey International’s planned launch of Raptor Packaging, a marketplace platform designed to bring buyers and sellers of rigid packaging together. The company aims to revolutionize the future of procurement in the market by leveraging a wealth of state-of-the-art tools.

Jason Small, COO, Raptor Packaging, says “industries are changing so rapidly with the advancement of new web-based technologies, that what was once unachievable is now a reality.”

-In Asia, they have not reached an agreement on the May contract prices of para-xylene.

The participants in the negotiation process to agree on the May contract prices of paraxylene in Asia failed to reach an agreement for the next month amid an uncertain market situation, market sources told ICIS .

According to them, the approval of the monthly contractual price of the material is achieved when it is agreed by at least two suppliers and two buyers.

The last price range, within which negotiations were conducted, was USD930-1,050 per tonne, CFR Asia, market participants said.

-French Machinery Manufacturers to Evaluate Opportunities at ITMA 2019

French machinery manufacturers to evaluate opportunities at ITMA 2019. One of the most important participants of ITMA fairs, French machinery manufacturers will participate in this year’s edition by highlighting the themes of innovation and reliable partnership. UCMTF will continue to support its members in order to increase the industry’s share in the global market.

French machinery manufacturers develop high-tech solutions for textile manufacturing processes from spinning to weaving, dyeing and finishing to technical textiles, and will present their competence in this area at the ITMA 2019. Evelyne Cholet, Secretary General of UCMTF, a member of ITMA’s organizer CEMATEX, issued a special statement to Textilegence about the preparations for the upcoming ITMA 2019 and the contributions of UCMTF to the industry.

-Virgin plastics producer acquires recycled compounder

Closeup of plastic resins of various colors.Multinational oil and gas company MOL Group will acquire a German recycled plastics compounder.

The Hungarian energy giant has agreed to acquire Aurora, which produces engineering plastics and recycled PP-based compounds. Aurora supplies automakers and other manufacturers.

The investment allows MOL to offer polyamide, PP and other recycled-content compounds alongside its virgin PP and PE, according to a press release.

The acquisition is the latest case of a petrochemicals company buying a plastics reclaimer. In Europe, Indorama Ventures acquired French PET and HDPE reclaimer Sorepla Industrie, Total acquired French PP reclaimer Synova and LyondellBasell became a partner in Netherlands HDPE and PP reclaimer Quality Circular Polymers (QCP).

Kern-Liebers to participate in ITMA 201901

Kern-Liebers Textiles will be represented by Kern-Liebers knitting parts, Saxonia and Leistner at ITMA from May 20 in Barcelona. Under the umbrella brand Kern-Liebers, the company offers a complete range of needles, components for weft and warp knitting machines. The entire range of the company’s parts and needles will be presented at the exhibition.

“Because the warp knitting market is creating more and more complex end products, the technical requirements for these products, and in particular for blocks, are constantly increasing. Meeting these increased requirements again and again presents new challenges for our developers, but it also means that we achieve the highest standards in terms of quality, the lifespan of our end products, and development expertise,” Kern-Liebers said in a press release.

-Oil prices fall as U.S. crude stocks climb to highest since September 2017

Oil futures sank about 1% on Wednesday after U.S. crude inventories in the United States soared more than expected to their highest since September 2017 as production hit a record high of 12.3 million barrels per day.

The declines were somewhat tempered by the intensifying crisis in Venezuela and Washington’s stopping Iranian oil sanction waivers as of May 1, with the fall in the global Brent benchmark more muted.

-MBA Polymers UK announces acquisition of PPR Wipag

MBA Polymers UK has announced the acquisition of Dover based automotive plastics recycler PPR Wipag.

PPR Wipag are specialists in the processing of post industrial plastics from the automotive industry including complex multi-layered parts and converting them back into high quality closed loop resins.

MBA Polymers UK currently specialise in the processing of complex post consumer plastics from Automotive Shredder Residue (ASR) and Waste Electrical and Electronic Equipment (WEEE). These outputs are compounded, at their recycling facility, into high quality virgin replacement polymer grades.

-Working towards solving the Circular Economy challenge

In cooperation with major players such as Borealis and Nestlé, SYSTEMIQ initiated Project STOP in order to address the sustainability issues of the day. Elisabeth Skoda spoke to the company’s materials platform associates Julia Koskella and Jessica Stewart about ways to achieve a circular economy and the role the packaging industry can play.

Could you give us a quick overview of SYSTEMIQ’s work and, in particular, Project STOP?

SYSTEMIQ’s goal is to build the world’s leading system change company, combining coalition-building, advisory work with pioneer institutions, business incubation, venturing, and redirecting large-scale capital. We believe this shift to better markets can unlock economic value well in excess of US$10 trillion per year, in addition to massive social and environmental benefits.

-Pretium Packaging Acquires Olcott Plastics

Chesterfield, Missouri-based Pretium Packaging is acquiring St. Charles, Illinois-based Olcott Plastics Inc. This takeover will give Pretium access to Olcott’s long-standing business. Olcott started its injection molding plastic jars business nearly fifty years ago and still retains some of its initial customers. Presently, Olcott manufactures over 1 million jar and closure combinations for the applications in the health, personal care, and beauty sectors. Pretium is of the opinion that the deal will add the knowledge base of Olcott including their exceptional beauty care packaging expertise and a strong product range, which will enhance its portfolio.

The products of the plastics company will also be complementary to Pretium’s health and beauty care packaging segment. Olcott’s products comprise of injection mold making and decorating single- and double-wall polypropylene (PP) jars and seamless PET jars.

-US May benzene contracts increase with higher crude

US May benzene contracts increased 8 cents/gal ($24/tonne) on the back of higher spot prices in April associated with higher crude values.

US May benzene contracts increased to $2.33/gal FOB (free on board) USG (US Gulf) from $2.25/gal in April.

Ample supply in the global market extended by expectations of new capacity in the key China market limited the increase.

Increased benzene capacity as a coproduct of paraxylene (PX) production at Hengli Petrochemical’s new plant in Dalian, China, is weighing on the market, with May benzene trading at a 4.5 cent premium to June on Tuesday afternoon.

Increased capacity and easing crude futures have the potential to stop the uptrend in US benzene contracts, which have steadily increased since the start of 2019.

-Autefa to offer future-proof solutions at Techtextil

Autefa Solutions, a full line supplier for carded- crosslapped needlepunch lines and thermobonding lines, will offer future-proof solutions for improving quality and productivity at the upcoming Techtextil trade fair that take place from 14-17 May in Frankfurt.

During Techtextil, the company will present its portfolio. Autefa Solutions lines cover the needs of the highly-competitive nonwovens market. “An improved and even surface quality has been set as key target by the customers,” the company reports. “Therefore, Autefa Solutions offers the service of a customised needle board pattern.”