Plastic-Recycling – Cirular-Economy 20-09-2022 - Arhive

Plastic-Recycling – Cirular-Economy

Crude Oil Prices Trend

-EU Commission proposes to cut €7.5 billion funding to Hungary

Citing worries over corruption in Hungary, the European Commission proposed on Sunday (18 September) to suspend one-third of the cohesion funds allocated to the country if its reform efforts remain insufficient in the coming two months.

In a meeting on Sunday morning, the EU executive proposed suspending €7.5 billion in EU funding for Budapest, or about a third of the total amount of cohesion funds that Hungary is allocated until 2027.

The suspension is focused on programmes that are heavy on public procurement and therefore most vulnerable to corruption. Moreover, the Commission will demand that EU programmes like Horizon Europe should not commit any money to Hungarian public interest trusts.

“Today’s decision is a clear demonstration of the Commission’s resolve to protect the EU budget, and to use all tools at our disposal to ensure this important objective,” the EU’s Budget Commissioner Johannes Hahn said in a statement.

The conditionality mechanism shows its teeth

The Commission acted on the basis of the conditionality mechanism that has been part of the EU’s budget rules since January 2021. It allows the EU to suspend payments to member states in cases where breaches of rule of law principles risk affecting the EU’s financial interests. Plastic-Recycling – Cirular-Economy

Worried about Hungary’s slide towards autocracy under Prime Minister Viktor Orbán, the European Parliament has long pushed the Commission to trigger the conditionality mechanism, which the EU executive did in April.

It also notified the Hungarian government of its concerns, but in its reply, Budapest denied the corruption allegations and offered no measures to remedy the situation.

That is why the Commission sent another letter to the Hungarian government in July to inform it of the measures it intended to propose.

“That seems to have focused the minds in Budapest,” an EU official said.

Over the summer, the Hungarian government came forward with a set of 17 measures in a bid to dissipate the Commission’s concerns, for example, the establishment of an independent “Integrity Authority” and an anti-corruption task force that would involve civil society.

-Lenzing also switches to green electricity at its Chinese site

- Gradual transition to green electricity will significantly reduce annual carbon emissions

- Milestone in the transformation of production capacities to TENCEL™ branded modal fibers

Nanjing – The Lenzing Group, a world-leading provider of wood-based specialty fibers, is continuing to expand its global clean electricity portfolio by gradually transitioning to green energy at its production site in Nanjing. This will enable its Chinese subsidiary Lenzing Nanjing Fibers to use electricity derived solely from renewable sources from 2023 onwards and reduce the site’s carbon emissions by 100,000 tonnes annually. Lenzing only recently announced the transition to green electricity at its Indonesian production facility.

In 2019, Lenzing became the first fiber producer to set a target of halving its carbon emissions by 2030 and becoming climate neutral by 2050. This carbon reduction target has been recognized by the Science Based Targets Initiative. In Nanjing, Lenzing is currently investing in cutting its carbon emissions and converting a standard viscose production line to 35,000 tonnes of TENCEL™ branded modal fibers. Thanks to this move, the Chinese site will exclusively produce eco-friendly specialty fibers.

“Demand for our wood-based, biodegradable specialty fibers is constantly rising. We see enormous growth potential, especially in Asia. Thanks to our investments in China and other Lenzing sites around the world, we will be better positioned to meet this growing demand in future. At the same time, we are continuing to make considerable progress towards achieving a carbon-free future and becoming a champion of circularity,” comments Robert van de Kerkhof, Chief Commercial Officer for Fiber at Lenzing.

Boosting growth in specialty fibers

Man-made climate change is one of the most pressing problems of our time. The fashion industry has an extremely negative impact on the environment due to its fast fashion business model and the growing consumption of fossil resources in textile production. Lenzing’s sustainably produced specialty fibers under the TENCEL™ brand help its customers, especially brands and retailers, to reduce their global footprint immensely.

Specialty fibers are Lenzing’s key strength. The company aims to generate more than 75 percent of its fiber revenue from the wood-based, biodegradable specialty fibers business under the TENCEL™, LENZING™, ECOVERO™ and VEOCEL™ brands by 2024. With the launch of the lyocell plant in Thailand in March 2022 and the investments in existing production sites in China and Indonesia, the share of specialty fibers in Lenzing’s fiber revenue is set to exceed the 75 percent target by a significant margin as early as 2023.

-Oil Industry Pioneer Starts Strategic Review to End Refining in Finland

Neste Oyj, Finland’s only oil refiner, has begun studying how it will end the processing of crude in the Nordic country by the middle of the next decade.

The world’s biggest maker of renewable diesel said its refinery in Porvoo, which already makes biofuels, would undergo a transformation starting with the co-processing of both renewable and circular feedstock, according to a statement. A spokeswoman contacted by Bloomberg News verified the statement.

The transition could continue with retrofits of existing units at a later stage and the targeted transformation would lead to a discontinuation of crude oil refining in Porvoo in the mid-2030s, the company said. It will also continue to actively study opportunities of green hydrogen at the site.

Neste is seen as somewhat of a pioneer in the oil industry having made its first investment in renewable diesel — a product made entirely from renewable raw materials — as early as 2005. After initially being unprofitable, the product overtook traditional oil products as the company’s main profit driver in 2018. The refiner is also processing sustainable aviation fuel from waste and makes renewable polymers and chemicals.

-the family car according to Ferrari

In the making for a very (very) long time at Ferrari, the very first four-door, four-seater car from the Italian brand was eagerly awaited. Very recently, it was within the Teatro del Silenzio located in Lajatico, in the province of Pisa, that the Italian manufacturer lifted the veil on its new creation: Purosangue. A family car that promises to combine increased space with the company’s famous performance.

Ferrari Purosangue, pur-sang italien

Side look, this new Ferrari Purosangue oscillates between the station wagon and the SUV, although the manufacturer does not use this name at any time. For Ferrari, the Purosangue is a vehicle derived from “of a new segment“, which is characterized in particular by rear-hinged passenger doors. According to Ferrari, this allows the passenger to get in and out of the car with ease without having to increase the size of the vehicle.

Under the hood is a 725bhp 6.5-litre V12 engine (without the slightest trace of electrification here), painstakingly tuned to give the driver seemingly endless power under his right foot, with a dual-clutch transmission at eight speeds and cylinder heads derived from the formidable 812 Competizione. Enough to go from 0 to 100 km/h in just 3.3 seconds, and from 0 to 200 km/h in a record time of 10.2 seconds.

Ferrari also promises a vehicle “durable“, since 85% of the car’s launch finishes were produced with this in mind. Plastic-Recycling – Cirular-Economy

Also, the fabric headlining is made from recycled polyester, the carpet is made from recycled polyamide from fishing nets recovered from the oceans and the newly formulated Alcantara is also made from recycled polyester.

On board, the driver’s compartment inspired by the SF90 Stradale remains in the DNA of the Ferrari sports car. Note that the front passenger can also enjoy a dedicated 10.2” screen displaying performance figures in real time. That of the driver of course displays the counters, as well as the duplication of the smartphone thanks to Android Auto or Apple CarPlay.

On the availability side, Ferrari will play the exclusivity card, with a Purosangue which will be produced in limited quantities, with the first deliveries scheduled for the second quarter of 2023. On the price side, this new SUV Ferrari vehicle should be displayed from €390,000.

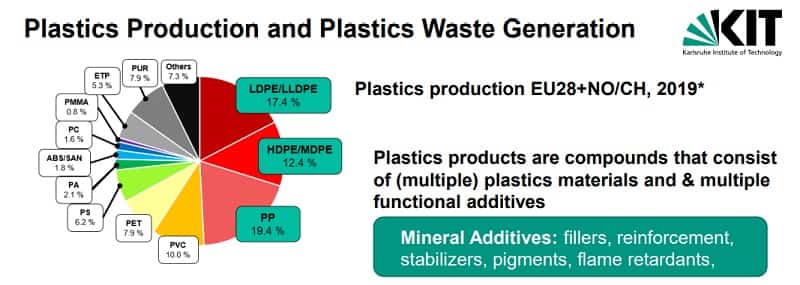

Plastics Production and Plastics Waste Generation

Total Plastics Waste Development, Recycling and Recovery in Germany

Recycling Processes for Mixed Plastics Waste and Key Products

Examples of Plastics Waste Produced Plastic-Recycling – Cirular-Economy

Pyrolysis Mass Balance – Pyrolysis Carbon Recovery – Pyrolysis Energy Balance – Upgrading of Pyrolysis Products to Secondary Petrochemical Feedstock –

Pyrolysis Oil Characterization* and Hydrotreatment – Case: Recycling of Light Weight Packaging Waste

-What is the current situation of recycled plastic in Europe?

Although the volume of plastic recycling in Europe has improved, initiatives are being developed to increase the weight of recycled plastic.

According to Eurostat, each European generates an average of 34 kilos of plastic packaging waste per year, of which around 14 kilos is recycled. Over the last decade, the volume of plastic packaging waste generated per inhabitant increased by 24%, while the recycling rate of plastic packaging waste grew by almost 50%.

However, there is considerable room for improvement in areas such as the collection of plastic waste, its arrival at recycling plants and the quality of some virgin plastic packaging, which prevents it from being reused or makes the recycling process more costly and complicated. Plastic-Recycling – Cirular-Economy

Initiatives that have been launched

For about a decade, the European Union (EU) has been strongly committed to favoring a circular economy. In the particular case of plastic, in 2015, the European Parliament approved the restriction of disposable plastic bags. Later, in 2018, the European Commission presented a proposal to tackle the amount of plastic waste that ends up in the sea, focusing on specific measures to combat single-use plastics.

Europe has been committed to circular economy for a decade by improving plastic recycling volume

A year later, in 2019, the European Green Pact called for 55% of plastic packaging waste to be recycled by 2030. In addition, other initiatives were developed, such as the introduction of quality standards for secondary plastics or the design of mandatory rules on the minimum recycled content of certain products. In parallel, the Commission has been issuing various standards in recent years aimed at reducing the volume of microplastics on the market.

How is plastic recycling done?

In Europe, the main recycled plastic material is PET thanks to its unique properties, which make it very attractive to many industries. These include its light weight, its transparency (which makes it ideal for consumer packaging, for example in the food sector), its high level of resistance and impermeability to microorganisms and liquids, its resistance to heat and abrasion, its great flexibility, and the fact that it is fully recyclable, in many cases indefinitely, and that it can be used for a wide range of applications.

-Will spandex prices rebound amid soaring BDO?

BDO-PTMEG-Spandex prices hit periodical bottom in Sep. Price of BDO soars due to low supply and growing demand, up by near 3,000yuan/mt compared with the year low by Sep 15. PTMEG plants intend to raise price but price still shivers at low level. Sales of spandex accelerate supported by low operating rate and recovering demand. Supply of some spandex varieties becomes tight. Downstream demand for spandex is supported by the traditional peak season expectation. Plastic-Recycling – Cirular-Economy

Will prices of spandex rebound?

Firstly, the cash flow of spandex value chain shrinks to low level, and supply obviously contracts. Supply of BDO is low with intensive production curtailment and suspension during the turnaround season in Sep, while demand grows. BDO price is revised up to lower losses. Demand for PTMEG touches bottom and gradually recovers. Sales of PTMEG increase in Sep. Supply of PTMEG rises while is obviously low. Price of PTMEG edges up stably. The cash flow of spandex 40D apparently decreased in Jul and Aug with substantially reducing PTMEG price while the spot profit increases to positive territory when price of spandex declines slower. The operating rate of spandex plants has been ascended to above 60% from 50%, remaining low.

Secondly, demand improves and sales of spandex rise. Sep and Oct are traditional peak season for fabric and textiles market. Downstream buyers turn to purchase normally to cover 7-20 days of production from only buying on a need-to-basis. Some downstream plants have replenished 1-month of spandex. The operating rate of downstream plants is advancing, especially warp knitting super-soft fabrics and circular knitted fabric producers. Spandex producers see apparently increasing sales. Stocks of spandex have fallen to above 36 days, down by near 15 days from high level. The delivery of some warp knitted spandex 40D is tight and needs to queue. Supply of 30D is also tight in some plants while that of 15-20D keeps abundant. Plastic-Recycling – Cirular-Economy

The operating rate of spandex downstream fabric mills has continued rising since late-Aug, with that of circular knitting plants at 30-50% in Zhejiang, Jiangsu, Guangdong and Fujian and that of warp knitting mills up to 50-70%, even above 70% in Haining. The run rate of lace knitting plants also advances. Most downstream plants witness better domestic orders, mainly for the online shopping spree in Nov and Dec, which can mostly guarantee production until end-Sep. Export orders also slightly grow.

-Circular economy: new EU rules to allow use of recycled plastics in food packaging

Today, the Commission has adopted new rules on the safety of recycled plastic materials and articles intended to come into contact with food.

This Regulation will set clear rules to ensure that recycled plastic can be safely used in food packaging in the EU.

It will contribute to increasing the overall sustainability of the food system and achieving the objectives of the Circular Economy Action Plan. Executive Vice-President for the European Green Deal, Frans Timmermans, said: “To lower our dependency on primary raw materials and build a fully circular economy, we need to boost the market for recycled plastics and significantly reduce plastic waste in the food sector and beyond. Plastics are useful to preserve food, but their use has to be sustainable.

Today’s new rules enable food manufacturers to use more recycled plastics in food packaging. This is an important step towards safe and sustainable use of recycled plastics in the food sector.” Plastic-Recycling – Cirular-Economy

Commissioner in charge of Health and Food safety, Stella Kyriakides, said: “The EU needs new rules to produce safe recycled plastics that can be trusted by food businesses and consumers. With around 50% of all plastic packaging in the EU used for food products, we need to ensure that this sector can transition towards a more sustainable food production safely and efficiently – using more recycled plastic is key to achieve this. Protecting our environment and the health of our citizens are two sides of the same coin, and our new rules will deliver on these objectives!” The Regulation makes it possible to authorise recycling processes for manufacturing safe recycled plastic materials for use in food packaging. It will also help the recycling industry establish suitable ways for recycling plastics that presently cannot be recycled into food packaging.

In addition, the European Food Safety Authority (EFSA) will have a clearer basis to evaluate the suitability of recycling technologies and the safety of the recycled plastic in food packaging manufactured with processes using these technologies.

The Regulation will allow granting individual authorisations for more than 200 mechanical PET (polyethylene terephthalate) recycling processes, which will help the industry to meet the binding 2025 target of 25% recycled plastic in PET beverage bottles.

In addition, the new Regulation will establish a public register of recycling processes, recyclers, and recycling installations under its scope, providing an increased level of transparency. Plastic-Recycling – Cirular-Economy

Plastic-Recycling – Cirular-Economy